A kind of production method of high-fiber blackberry whole pulp

A production method, blackberry technology, applied in food ingredients containing natural extracts, food science, application, etc., can solve the problems of waste of resources, pollution of the environment, sour and smelly, etc., to achieve improved grades, uniform particle size distribution, and improved digestion and absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Production of high-fiber blackberry whole pulp.

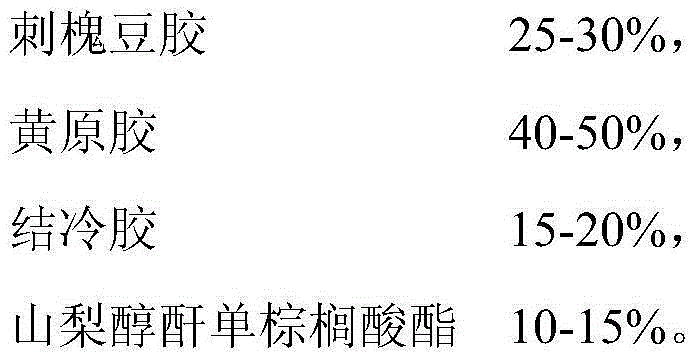

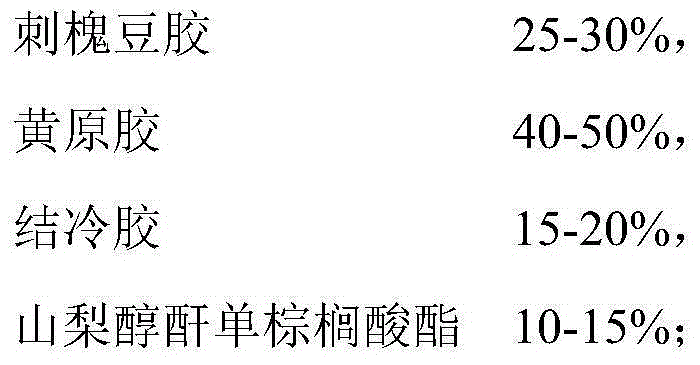

[0024] Spray the cleaned ripe blackberry fresh fruit (or thawed frozen fruit) with high-pressure steam (0.15-0.2MPa) for 1min, cool it quickly with cold air (2-4°C) to below 10°C, make a pulp, and add 0.3% blackberry pulp by weight Cellulase (100000~200000U / g, Tai'an Xindeli Biological Engineering Co., Ltd.), 0.2% composite stabilizer of blackberry slurry weight (composite stabilizer is made of locust bean gum of 25% by mass percentage composition, 50% yellow Raw gum, 15% gellan gum, 10% sorbitan monopalmitate), mix homogeneously, high-speed cutter pulverizer (Jiangnan University Food Equipment Engineering Research Center) superfine pulverization, rotating speed 10000rpm, cycle 3 times, then Under the pressure of 150MPa, the dynamic ultra-high pressure treatment (Microfluidics Company of the United States) is carried out. The treated materials are sterilized at 135-140°C for 2-4 seconds, cooled to 30-40°C, ...

Embodiment 2

[0029] Embodiment 2: Production of high-fiber blackberry whole pulp.

[0030] Spray the cleaned ripe blackberry fresh fruit (or thawed frozen fruit) with high-pressure steam (0.15-0.2MPa) for 0.5min, cool it quickly with cold air (2-4°C) to below 10°C, make a pulp, and add 0.1% of the weight of the blackberry slurry Cellulase (100000~200000U / g, Tai'an Xindeli Biological Engineering Co., Ltd.), 0.4% composite stabilizer of blackberry slurry weight (composite stabilizer consists of locust bean gum that is 30% by mass percentage, 40% Xanthan gum, 15% gellan gum, 15% sorbitan monopalmitate), mix homogeneously, high-speed cutting pulverizer (Jiangnan University Food Equipment Engineering Research Center) superfine pulverization, rotating speed 9000rpm, cycle 4 times, then Under the pressure of 100MPa, dynamic ultra-high pressure treatment (Microfluidics Company of the United States) is carried out, and the processed materials are sterilized at 135-140°C for 2-4 seconds, cooled to 3...

Embodiment 3

[0031] Embodiment 3: Production of high-fiber blackberry whole pulp.

[0032] Spray the cleaned ripe blackberry fresh fruit (or thawed frozen fruit) with high-pressure steam (0.15-0.2MPa) for 1.5min, cool it quickly with cold air (2-4°C) to below 10°C, make a pulp, and add 0.5% of the weight of the blackberry slurry Cellulase (100000~200000U / g, Tai'an Xindeli Biological Engineering Co., Ltd.), 0.3% composite stabilizer of blackberry slurry weight (composite stabilizer is composed of locust bean gum of 30% by mass percentage, 40% Xanthan gum, 20% gellan gum, 10% sorbitan monopalmitate), mix uniformly, high-speed cutting pulverizer (Jiangnan University Food Equipment Engineering Research Center) superfine pulverization, rotating speed 10000rpm, cycle 2 times, then Under the pressure of 200MPa, dynamic ultra-high pressure treatment (Microfluidics Company of the United States) is carried out. The treated materials are sterilized at 135-140°C for 2-4 seconds, cooled to 30-40°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com