Method for continuously manufacturing high-silicon steel sheet and continuous casting device

A high-silicon steel sheet and high-silicon steel technology is applied in the field of melting preparation of silicon steel alloys, which can solve the problems of product compactness, high cost, shortened life and other problems, achieve small thickness variation, improve surface quality, and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

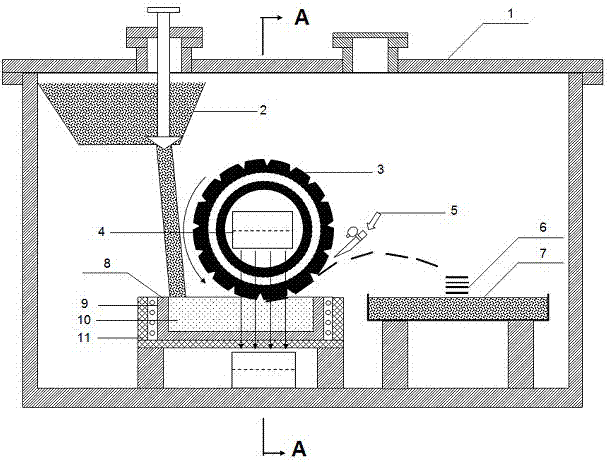

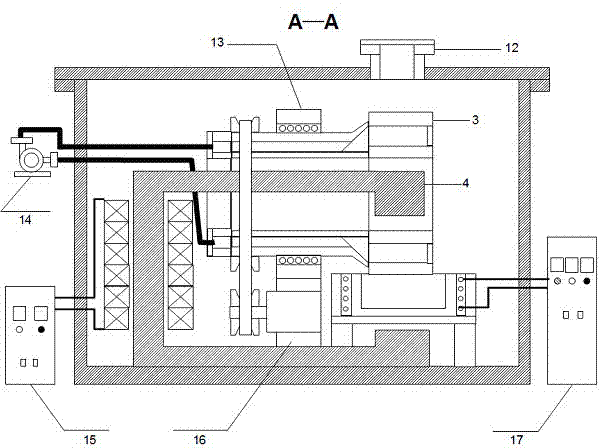

[0035] In this example, see figure 1 and figure 2 , a high-silicon steel sheet continuous casting device, mainly composed of a feeding device 2, a crucible 8, a continuous casting machine body and a heating control device, the crucible 8 contains molten metal 10, and the molten metal 10 is added to the crucible 8 through the feeding device 2 The heating control device is composed of a heating body 9 and a heating power supply 17. The heating power supply 17 supplies power to the heating body 9. The heating body 9 is arranged outside the crucible 8 to heat the molten metal 10. The feeding control system of the feeding device 2 , make the surface of the molten metal 10 in the crucible 8 stable, and keep the liquid level of the molten metal 10 in the crucible 8 stable. Between the outer wall and the inner wall of the heat insulating sleeve 11, the continuous casting machine body is mainly composed of a magnetic field generating device, a silicon steel sheet continuous casting s...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, the main body of the continuous casting machine is placed in a vacuum environment through a vacuum pump. The vacuum pump is a Roots vacuum pump, and a regulating valve is connected in series at the air suction port to maintain the vacuum degree through the control of the regulating valve. Stable, so that the entire continuous casting process is in a vacuum environment, so that the continuous preparation of high-silicon steel sheets can proceed smoothly.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this embodiment, the cooling water enters the inner cavity of the water-cooled copper plate 3 from the water inlet pipe, and adopts the multi-input and multiple-outlet mode. The water-cooled copper plate 3 is made of red copper, which has a much better cooling effect than the commonly used water-cooled plate. Due to the large heat capacity of the copper material, it can exchange with the cooling water to the maximum extent, which improves the cooling rate of the molten alloy liquid. One end of the water-cooled copper plate 3 is connected to a 300Kw DC drive motor 16 and a series of controllable speed-regulating devices. The speed of the drive motor 16 is 5000 rpm; the other end adopts a water-sealed dynamic seal. The depth of contact between the toothed water-cooled copper plate 3 and the molten metal 10 can be continuously and accurately adjusted; by controlling the immersion depth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com