Method for producing corn liquid fertilizer by sisal hemp wastewater

A technology of sisal waste water and sisal waste residue, applied in liquid fertilizer, sewage/sludge fertilizer, nitrogen fertilizer, etc., can solve pollution and other problems, achieve the effect of solving environmental pollution problems, low production cost, and wide sterilization spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

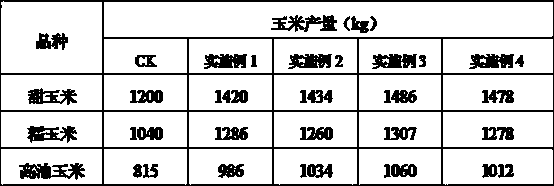

Examples

Embodiment 1

[0033] Raw material formula ratio: 650 kg of fresh sisal waste water, 72 kg of urea (containing N as 46.0%), 64 kg of diammonium phosphate (containing N as 16%, containing P 2 o 5 According to 46.0%, 2 kg of calcium magnesium phosphate fertilizer (containing P 2 o 5 18.0%, 9% Mg, 28.4% Ca, 12.7% Si), 72 kg potassium sulfate (K2 O is 50.0%, S is 17.0%, trace elements 0.5 kg (copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, sodium tetraborate), organic acid 1.0 kg (citric acid, oxalic acid, acetic acid, malic acid ), botanical fungicide 0.1 kg.

[0034] Production method of corn liquid fertilizer: the production process is as follows: according to the above formula, take fresh sisal wastewater, inorganic fertilizer, medium elements, trace elements, organic acid and botanical fungicide, stir and mix evenly, and then put them into a closed fermenter Fermentation is carried out at a temperature of 30-50° C., and the fermentation time is 10-15 days. Then the ferm...

Embodiment 2

[0036] Raw material formula ratio: 700 kg of fresh sisal waste water, 93 kg of urea (containing N as 46.0%), 81 kg of diammonium phosphate (containing N as 16%, containing P 2 o 5 According to 46.0%, ), calcium magnesium phosphate fertilizer 3 kg (containing P 2 o 5 18.0%, 9% Mg, 28.4% Ca, 12.7% Si), 93 kg potassium sulfate (K 2 O is 50.0%, S is 17.0%), trace elements are 0.6 kg (copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, sodium tetraborate), organic acids are 1.5 kg (citric acid, acetic acid, malic acid), Plant source fungicide 0.2 kg.

[0037] Production method of corn liquid fertilizer: the production process is as follows: according to the above formula, take fresh sisal wastewater, inorganic fertilizer, medium elements, trace elements, organic acid and botanical fungicide, stir and mix evenly, and then put them into a closed fermenter Fermentation is carried out at a temperature of 30-50° C., and the fermentation time is 10-15 days. Then the fer...

Embodiment 3

[0039] Raw material formula ratio: 720 kg of fresh sisal waste water, 110 kg of urea (containing N as 46.0%), 96 kg of diammonium phosphate (containing N as 16%, containing P 2 o 5 According to 46.0%, ), 4 kg of calcium magnesium phosphate fertilizer (containing P 2 o 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 110 kg of potassium sulfate (containing K 2 O is 50.0%, S is 17.0%), trace elements are 0.8 kg (copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, sodium tetraborate), organic acids are 1.8 kg (citric acid, acetic acid, malic acid), Plant source fungicide 0.4 kg.

[0040] Production method of corn liquid fertilizer: the production process is as follows: according to the above formula, take fresh sisal wastewater, inorganic fertilizer, medium elements, trace elements, organic acid and botanical fungicide, stir and mix evenly, and then put them into a closed fermenter Fermentation is carried out at a temperature of 30-50° C., and the fermentation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com