Production technique of norbornene

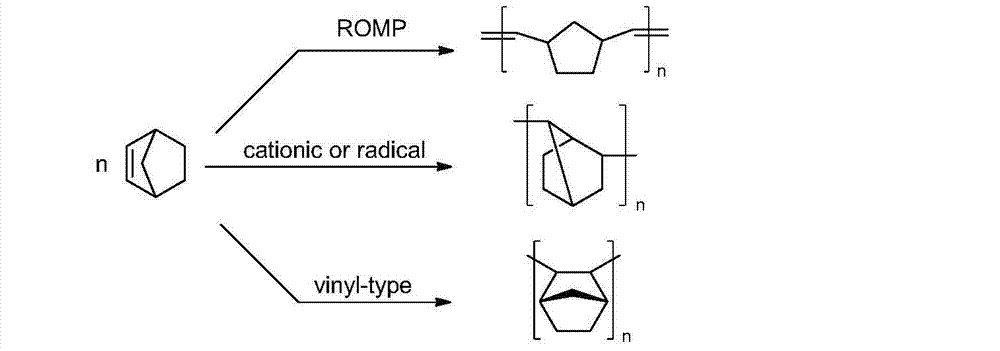

A norbornene and production process technology, applied in the field of norbornene production process, can solve the problems that dicyclopentadiene is prone to polymerization and cannot be produced continuously, so as to achieve high product purity, avoid the generation of water vapor, and slow down carbonization problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

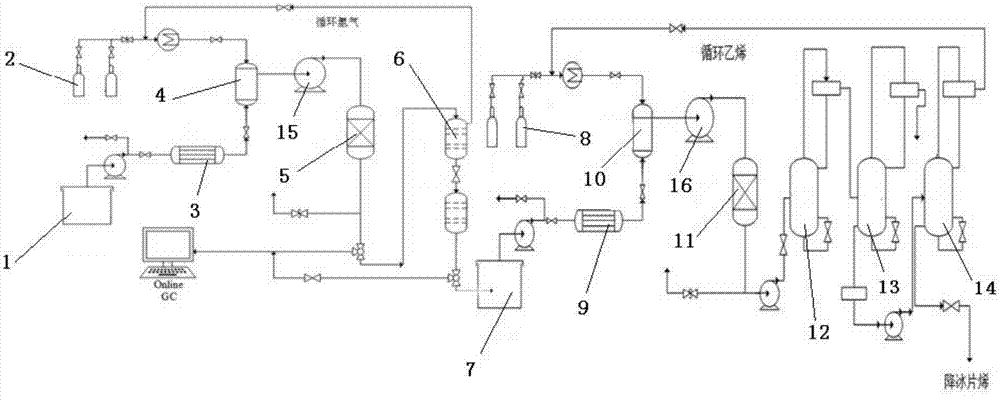

[0034] Adjust the temperature control systems, instruments and valves of the pilot plant in advance, and conduct leak detection. Add the dicyclopentadiene in the dicyclopentadiene storage tank 1 to the first heater 3 for preheating with a metering pump. The heating temperature is 170° C., and the vapor pressure is controlled at 10 MPa by adjusting the temperature. The hydrogen in the hydrogen storage tank 2 is preheated, and the dicyclopentadiene gas produced is mixed with the preheated hydrogen at a molar ratio of 1:30 in the first static mixer 4, and the mixed gas is pumped through the first metering pump 15 Into the first reactor 5, the feed flow rate of the first metering pump 15 is controlled to be 1mL / min, and cracking is carried out under the protection of excess hydrogen. In the first reactor 5, the controlled cracking temperature is 300 ° C, the reaction time is 10s, and the pressure is 10MPa. The mixture of products and reactants is drawn from the first reactor 5, a...

Embodiment 2

[0036]Adjust the temperature control systems, instruments and valves of the pilot plant in advance, and conduct leak detection. Add the dicyclopentadiene in the dicyclopentadiene storage tank 1 to the first heater 3 for preheating with a metering pump. The heating temperature is 190° C., and the vapor pressure is controlled at 15 MPa by adjusting the temperature. The hydrogen in the hydrogen storage tank 2 is preheated, and the dicyclopentadiene gas produced is mixed with the preheated hydrogen at a molar ratio of 1:40 in the first static mixer 4, and the mixed gas is pumped through the first metering pump 15 Into the first reactor 5, the feeding speed of the first metering pump 15 is controlled to be 1.5mL / min, and cracking is carried out under the protection of excess hydrogen, the cracking temperature of the first reactor 5 is controlled to be 310 ° C, and the reaction time is 8s. The pressure is 15MPa. The mixture of products and reactants is drawn from the top of the fir...

Embodiment 3

[0038] Adjust the temperature control systems, instruments and valves of the pilot plant in advance, and conduct leak detection. Add the dicyclopentadiene in the dicyclopentadiene storage tank 1 to the first heater 3 for preheating with a metering pump. The heating temperature is 210° C., and the vapor pressure is controlled at 20 MPa by adjusting the temperature. The hydrogen in the hydrogen storage tank 2 is preheated, and the dicyclopentadiene gas produced is mixed with the preheated hydrogen at a molar ratio of 1:50 in the first static mixer 4, and the mixed gas is pumped through the first metering pump 15 Into the first reactor 5, control the feed flow rate of the first metering pump 15 to 2mL / min, carry out cracking under the protection of excess hydrogen, control the cracking temperature to be 320°C, the reaction time is 6s, and the pressure is 20MPa. The mixture of products and reactants is drawn from the top of the first reactor 5, and enters the rectification equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com