Method for preparing 1,4,5,8-tetraaminonaphthalene tin chloride hydrochloride

A technology of tetraaminonaphthalene tin chloride and hydrochloride is applied in the preparation of amino compounds, the preparation of organic compounds, chemical instruments and methods, etc., and can solve the problems of difficult industrialized scale-up production, cumbersome post-processing, and many by-products, etc. Achieve the effect of increased fiber surface energy, good wettability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

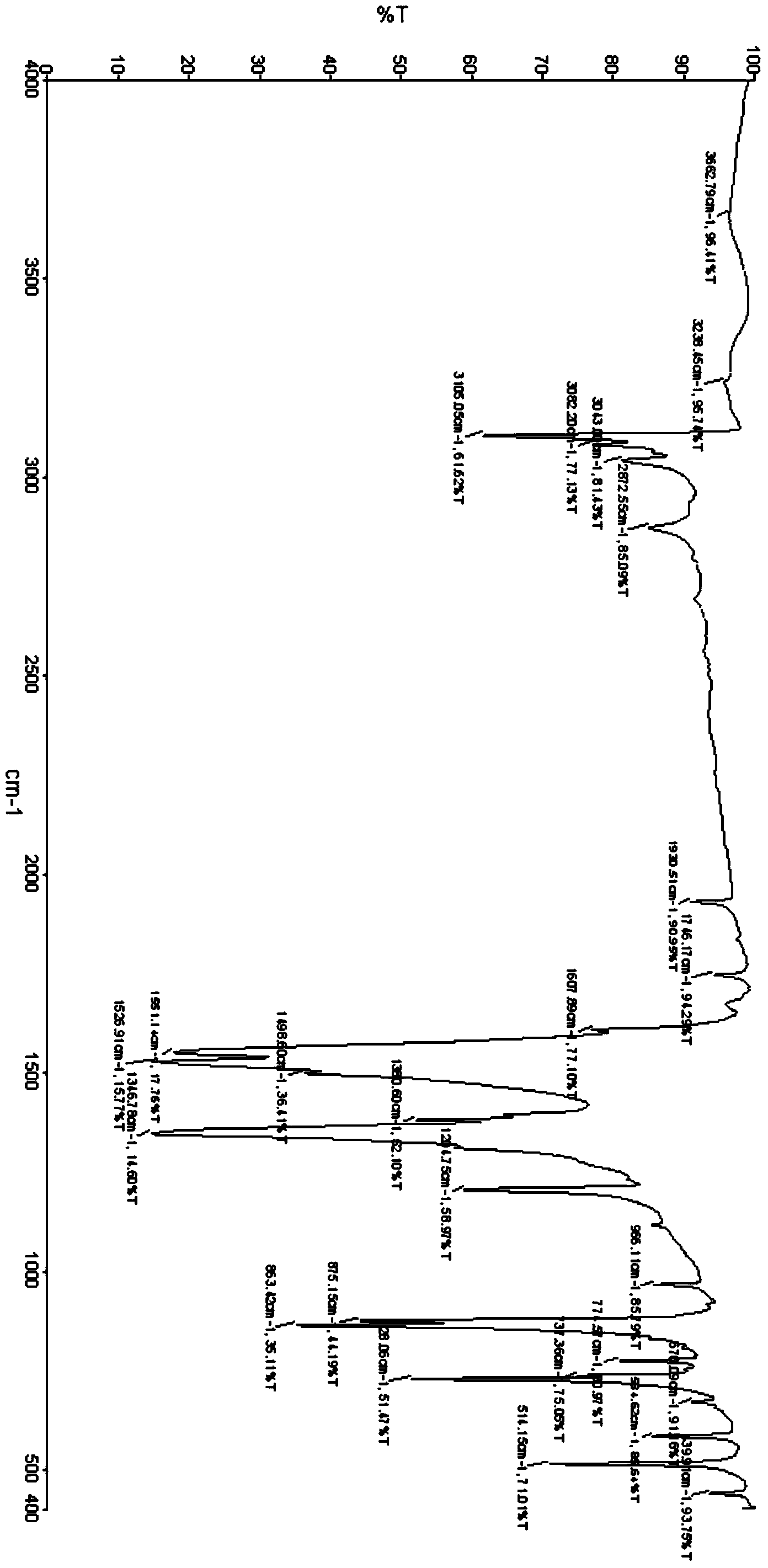

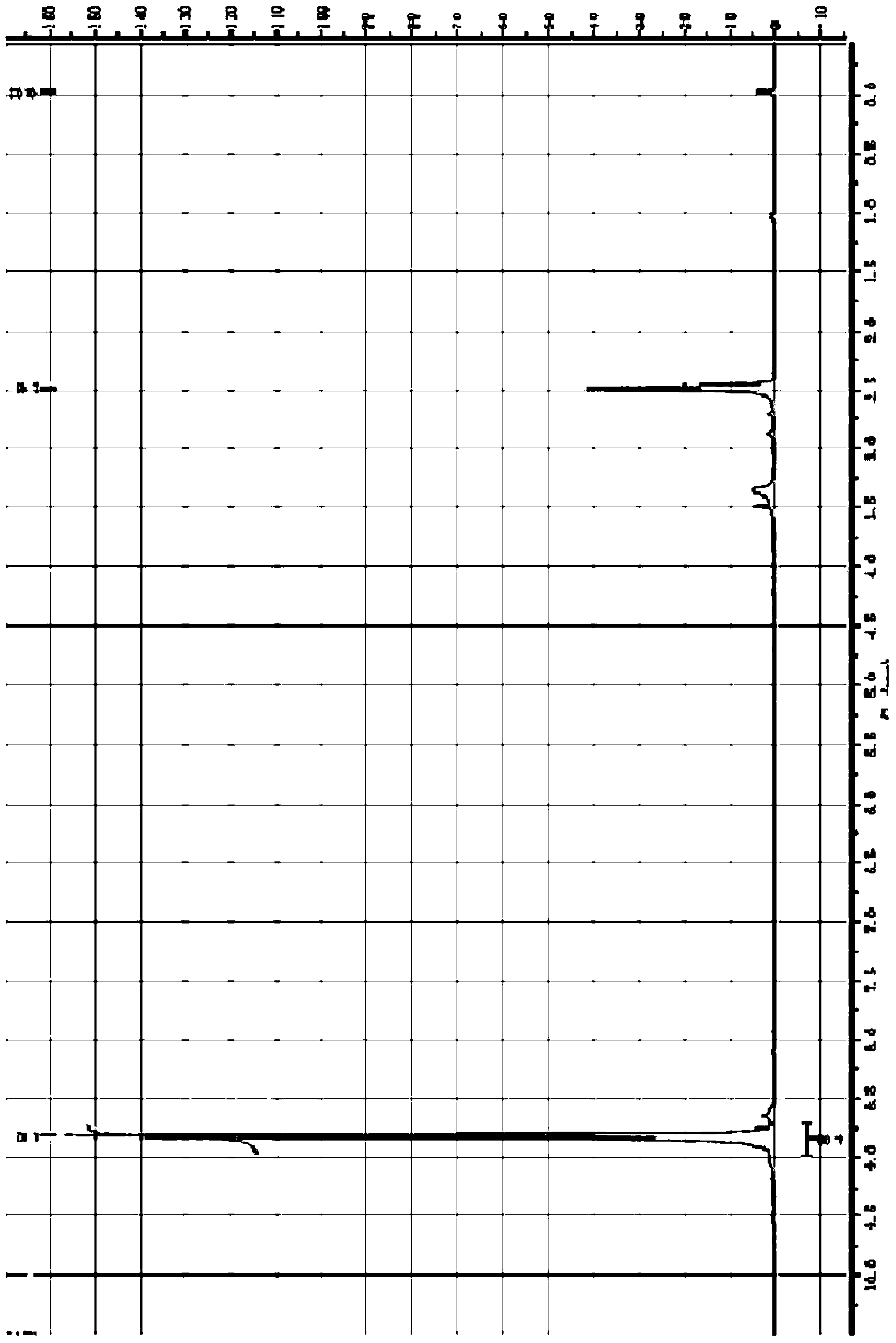

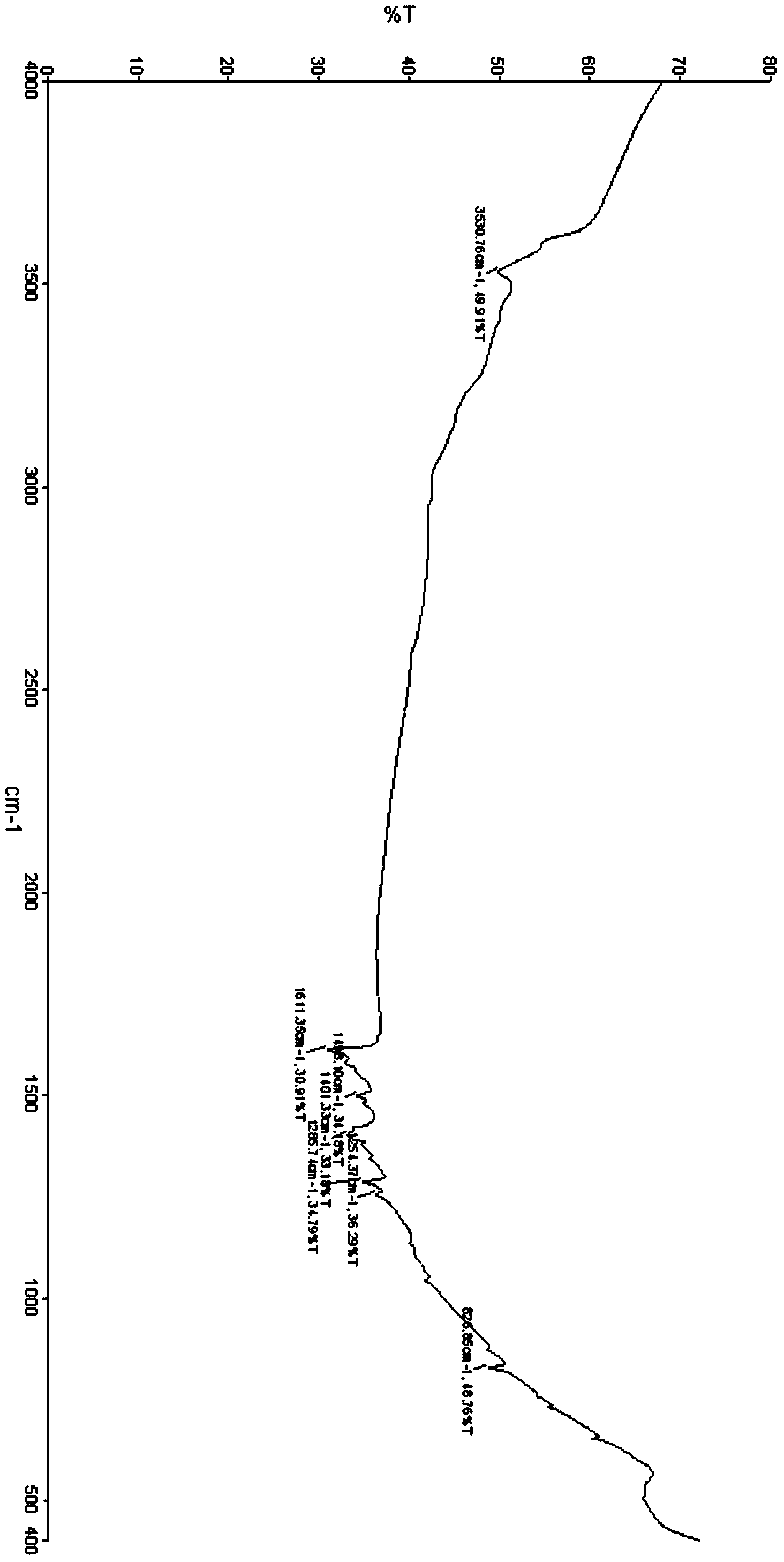

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment 1: The preparation method of 1,4,5,8-tetraaminonaphthalene tin chloride hydrochloride in this embodiment is carried out according to the following steps:

[0019] 1. Using 1,5-dinitronaphthalene as the starting material, add it to the reaction flask at room temperature, add the nitrating reagent, and then heat to 40~100℃, keep the reaction temperature for 2~5h, and then cool to room temperature. The reaction mixture is then poured into an ice-water mixture, stirred, filtered, and washed with water until it is neutral to obtain crude 1,4,5,8-tetranitronaphthalene, and the solvent is recrystallized to obtain high purity 1,4, 5,8-Tetranitronaphthalene.

[0020] 2. Add organic solvent to the 1,4,5,8-tetranitronaphthalene obtained in step 1, then add concentrated hydrochloric acid and catalytic promoter, add reducing agent at a temperature of 30-40℃, keep it for 2~3h , Then heated to 50~100℃ for catalytic reduction reaction for 3~5h, cooled to room temperatur...

specific Embodiment approach 2

[0024] Specific embodiment two: This embodiment is different from specific embodiment one in that: the nitrating agent described in step one is a mixed solution of concentrated sulfuric acid and fuming nitric acid, a mixed solution of concentrated sulfuric acid and potassium nitrate or fuming nitric acid. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment is different from specific embodiment one or two in that: in step one, it is heated to 50-80° C. and kept for 3 to 4 hours for reaction. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com