Double-ester-group aliphatic chain organosilane quaternary ammonium salt type compounds and preparation and applications thereof

An organosilane, quaternary ammonium salt technology, applied in the field of mesoporous ZSM-5 silica-alumina molecular sieves, can solve problems such as unfavorable large-scale application, weak acidity, poor stability, etc., to improve the internal diffusion limit and keep the crystallinity intact , the effect of fast homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

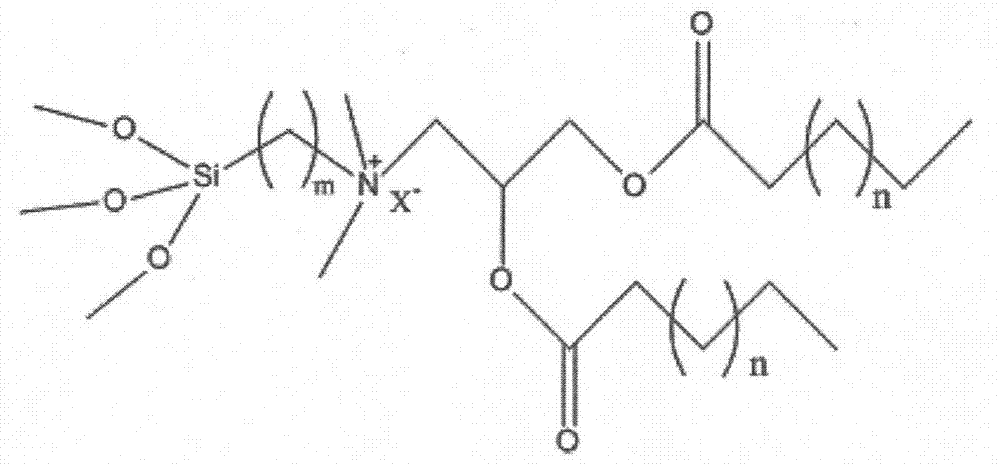

[0042] Synthesis of diester-based aliphatic chain (n=4) organosilane quaternary ammonium salt: Weigh 5g of hexanoic acid and 2g of 3-dimethylamino-1,2-propanediol, add the two to a 250mL three-necked flask, add 100mL Toluene, stir to mix evenly, heat up to 130°C at a heating rate of 1-5°C / min, reflux and divide water for 12 hours, wash the resulting mixed solution with water and 10% sodium carbonate solution repeatedly until no foam occurs , dry with anhydrous calcium chloride, obtain 1.8g diester-based aliphatic chain intermediate after column chromatography;

[0043]Add the intermediate obtained above and 2g (3-iodopropyl)trimethoxysilane into a 50mL round-bottomed flask, heat to 110°C at a heating rate of 1-5°C / min, and react for 24h under continuous stirring. After the reaction, Naturally cooled to room temperature, washed several times with anhydrous ether to obtain 2.3 g of diester-based aliphatic chain organosilane quaternary ammonium salt compound. Its structural form...

Embodiment 2

[0045] Synthesis of diester-based aliphatic chain (n=8) organosilane quaternary ammonium salt: Weigh 7g of lauric acid and 2g of 3-dimethylamino-1,2-propanediol, add the two to a 250mL three-necked flask, add 100mL Toluene, stir to mix evenly, heat up to 130°C at a heating rate of 1-5°C / min, reflux and divide water for 12 hours, wash the resulting mixed solution with water and 10% sodium carbonate solution repeatedly until no foam occurs , dry with anhydrous calcium chloride, obtain 2.3g diester-based aliphatic chain intermediates after column chromatography;

[0046] Add the intermediate obtained above and 3g (3-iodopropyl)trimethoxysilane into a 50mL round-bottomed flask, heat to 110°C at a heating rate of 1-5°C / min, and react for 24h under continuous stirring. After the reaction, Naturally cooled to room temperature, washed several times with anhydrous ether to obtain 2.8g diester-based aliphatic chain organosilane quaternary ammonium salt compound, its structural formula i...

Embodiment 3

[0048] Synthesis of diester-based aliphatic chain (n=12) organosilane quaternary ammonium salt: Weigh 8g of palmitic acid and 2g of 3-dimethylamino-1,2-propanediol, add the two to a 250mL three-necked flask, add 100mL of toluene, stir to mix evenly, heat up to 130°C at a heating rate of 1-5°C / min, reflux and divide water for 12h, wash the resulting mixed solution with water and 10% sodium carbonate solution repeatedly until no foam Produced, dried with anhydrous calcium chloride, and obtained 2.9g diester-based aliphatic chain intermediates after column chromatography;

[0049] Add the intermediate obtained above and 3.5g (3-iodopropyl)trimethoxysilane into a 50mL round bottom flask, heat to 110°C at a heating rate of 1-5°C / min, and react for 24h under continuous stirring. , naturally cooled to room temperature, washed several times with anhydrous ether to obtain 3.7g diester-based aliphatic chain organosilane quaternary ammonium salt compound, its structural formula is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com