Production method for food safety type monascorubin

A technology for monascus pigment and food safety, applied in biological engineering and fields, can solve problems such as affecting the quality of monascus pigment, and achieve the effects of reduced citrinin content, high safety, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Inoculate Monascus on solid slant medium and culture at 32°C for 5 days to obtain first-grade slant seeds. Solid slant medium: 6% glucose, 2% peptone, 3% agar, pH 5.5~6 ;

[0026] (2) Take one of the cultured slant seeds, elute the bacteria and spores with normal saline into 100ml of normal saline, inoculate it into the secondary liquid seed medium at 10% of the inoculation amount, and fill it in a 250ml triangular flask The volume is 100ml, add 20 glass beads, cultivate at 200rpm, 32°C for 24h-48h, the secondary seed medium is: rice flour 3%, sodium nitrate 0.5%, potassium dihydrogen phosphate 0.25%, magnesium sulfate heptahydrate 0.1 %, lactic acid to adjust pH5.5~6;

[0027] (3) Inoculate the secondary liquid seeds after 48 hours of cultivation into the fermentation medium at an inoculum amount of 6-10%. In a 300ml Erlenmeyer flask, the liquid volume is 100ml, and cultivate at 32°C and 200rpm for 6 days, and the fermentation medium For: rice flour 9%, sodium ni...

Embodiment 2

[0031] Steps (1)-(3) are the same as (1)-(3) in the method of Example 1.

[0032] (4) Add 100 μl of 2 mg / ml transforming agent B to the fermentation broth after 24 hours of cultivation;

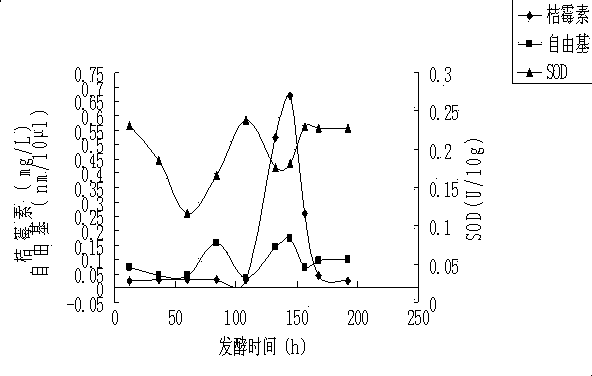

[0033] (5) During the fermentation process, samples were taken out at 12h, 36h, 60h, 84h, 108h, 132h, 144h, 156h, 168h, and 192h to measure color value, citrinin, superoxide dismutase (SOD) and free radicals . See results image 3 .

Embodiment 3

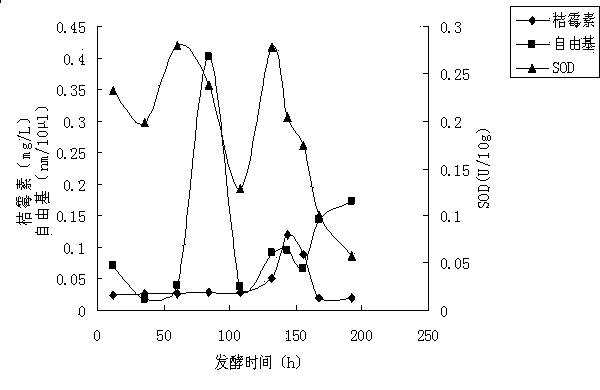

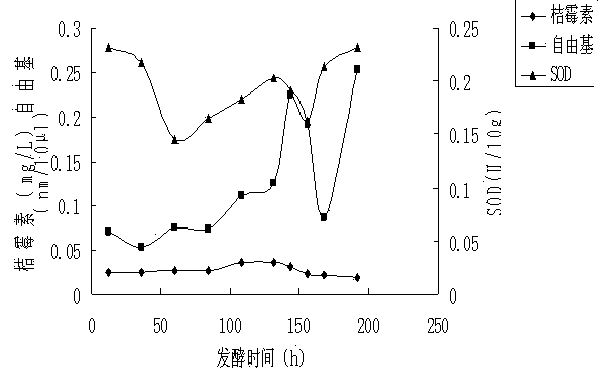

[0035] Steps (1)-(3) are the same as (1)-(3) in the method of Example 1. See results Figure 4 .

[0036] (4) Add 100ul 5mg / ml transforming agent C to the fermentation broth after 24 hours of cultivation.

[0037](5) During the fermentation process, one bottle was taken out at 12h, 36h, 60h, 84h, 108h, 132h, 144h, 156h, 168h, and 192h to measure color value, citrinin, superoxide dismutase (SOD) and free radicals. See results Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com