A kind of preparation method of tellurium-based composite thin film and its application in MIM capacitor

A technology of composite thin film and thin film capacitors, applied in the direction of thin film/thick film capacitors, multilayer capacitors, ion implantation plating, etc., can solve the problems of not having too high processing temperature, metal electrode oxidation, etc., to reduce production costs, avoid The effect of oxidation and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

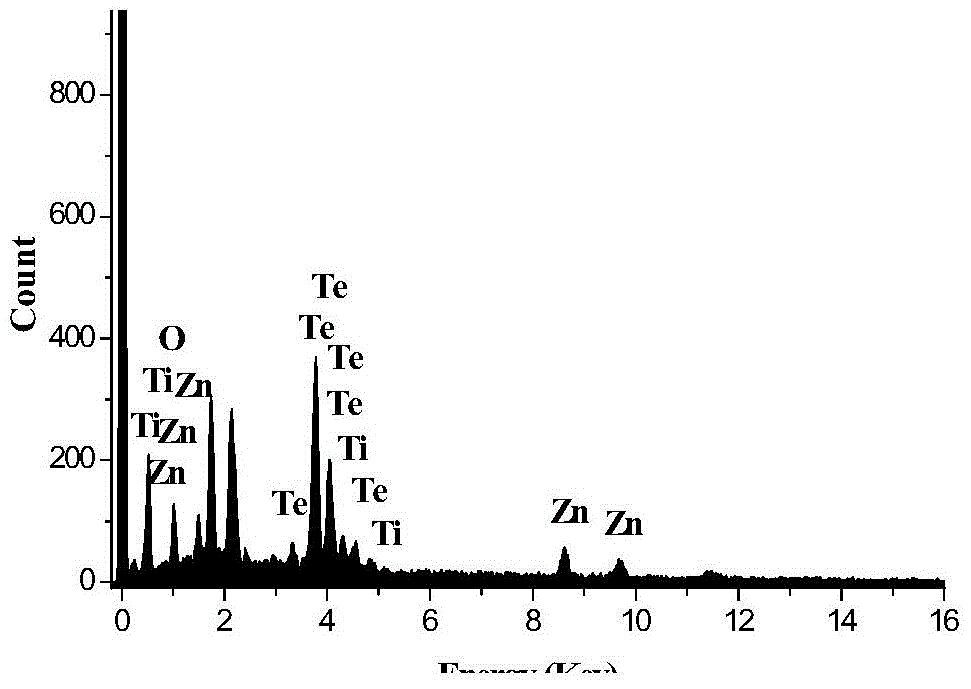

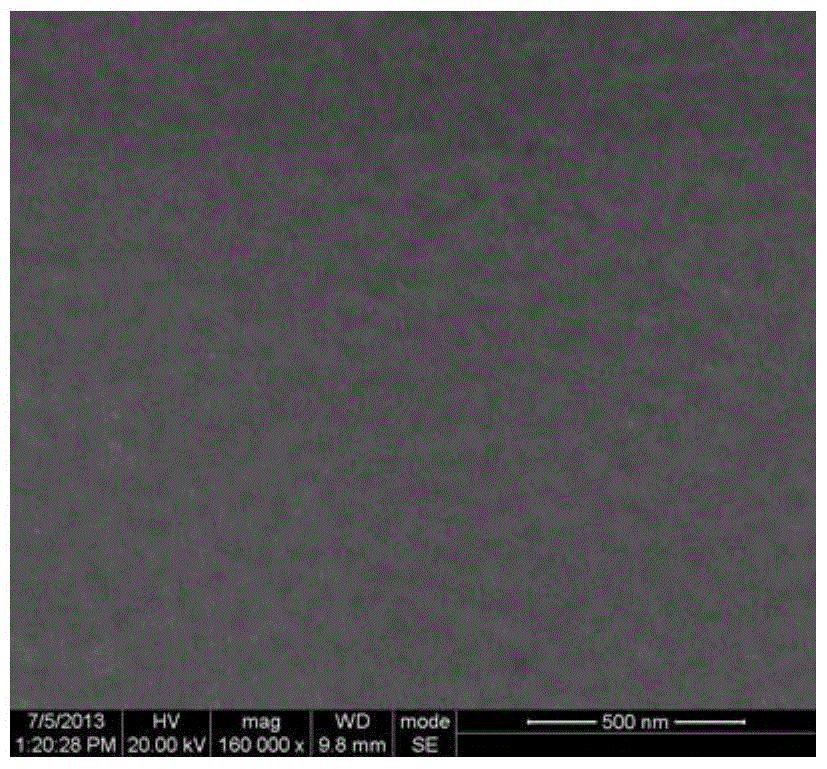

[0035] A preparation method for a tellurium-based composite thin film, comprising the following steps:

[0036] Step 1: Preparation of Zn by solid phase sintering method 2 Te 3 o 8 -TiTe 3 o 8 Composite ceramic target: ZnO 2 with TeO 2 Weighing and mixing according to the molar ratio of 2:3, ball milling for 24 hours and drying, TiO 2 with TeO 2 According to the molar ratio of 1:3, the materials were weighed and mixed, ball milled for 24 hours and dried, and the dried ZnO 2 -TeO 2 The powder is pre-calcined at 500°C to obtain Zn 2 Te 3 o 8 Powder, dried TiO 2 -TeO 2 The powder is calcined at 570°C to obtain TiTe 3 o 8 Powder; the Zn 2 Te 3 o 8 Powder and TiTe 3 o 8 The powder is weighed and mixed according to the mass ratio of 1:0.1~0.5, and ball milled for the second time. After drying, paraffin wax is added to granulate, and then placed in an oven for 30 minutes at 160°C~165°C, and cooled; the above dried powder Press into a disk with a diameter of 147mm...

Embodiment 1

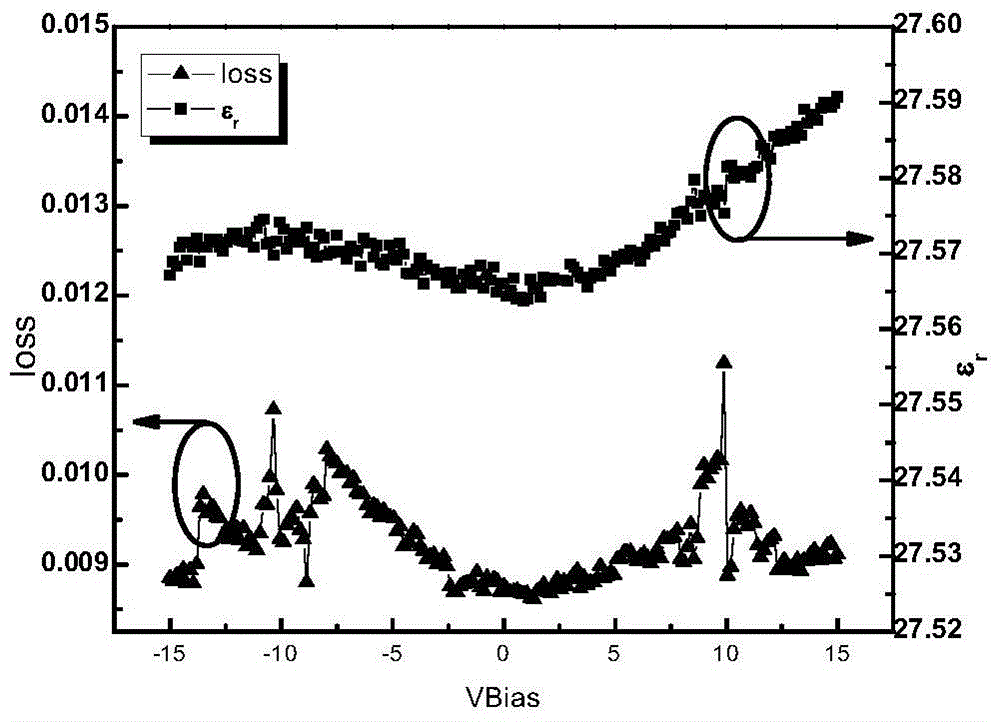

[0046] A tellurium-based composite film, the tellurium-based composite film is Zn 2 Te 3 o 8 and TiTe 3 o 8 A film formed by compounding at a mass percentage of 100:30.

[0047] A kind of MIM thin-film capacitor, from bottom to top successively is lower electrode metal layer, capacitor insulating layer, upper electrode metal layer, it is characterized in that, described capacitor insulating layer is a tellurium-based composite film, and described tellurium-based composite film is Zn 2 Te 3 o 8 and TiTe 3 o 8 A film formed by compounding at a mass percentage of 100:30.

[0048] A preparation method for a tellurium-based composite thin film, comprising the following steps:

[0049] Step 1: Preparation of Zn by solid phase sintering method 2 Te 3 o 8 -TiTe 3 o 8 Composite ceramic target: ZnO 2 with TeO 2 Weighing and mixing according to the molar ratio of 2:3, ball milling for 24 hours and drying, TiO 2 with TeO 2 According to the molar ratio of 1:3, the materia...

Embodiment 2

[0058] A tellurium-based composite film, the tellurium-based composite film is Zn 2 Te 3 o 8 and TiTe 3 o 8 A film formed by compounding at a mass percentage of 100:30.

[0059] A kind of MIM thin-film capacitor, from bottom to top successively is lower electrode metal layer, capacitor insulating layer, upper electrode metal layer, it is characterized in that, described capacitor insulating layer is a tellurium-based composite film, and described tellurium-based composite film is Zn 2 Te 3 o 8 and TiTe 3 o 8 A film formed by compounding at a mass percentage of 100:30.

[0060] A preparation method for a tellurium-based composite thin film, comprising the following steps:

[0061] Step 1: Preparation of Zn by solid phase sintering method 2 Te 3 o 8 -TiTe 3 o 8 Composite ceramic target: ZnO 2 with TeO 2 Weighing and mixing according to the molar ratio of 2:3, ball milling for 24 hours and drying, TiO 2 with TeO 2 According to the molar ratio of 1:3, the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com