A kind of synthesis method of superfine grain diamond single crystal

A diamond single crystal and ultra-fine particle technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of inability to obtain equal-volume particles, difficulty in meeting precision polishing, and disordered particle shapes, and achieve Improve the color and purity, promote a large number of nucleation, and improve the effect of uniform nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

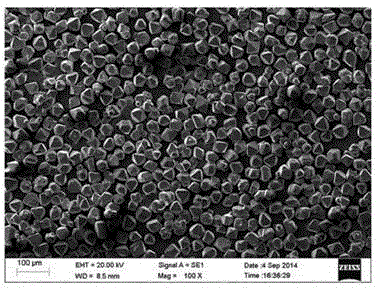

Embodiment 1

[0031] The synthetic method of superfine particle diamond single crystal of the present invention, detailed steps are as follows:

[0032] a. Mixing of graphite powder and catalyst powder: take graphite powder (spherical graphite with an impurity content less than 20ppm, the particle size of graphite powder is 600-1000 mesh) and catalyst powder according to the weight ratio of 4:6 and mix them;

[0033] Graphite powder is baked in the oven for 5 hours before use, and the baking temperature is 200°C;

[0034] The catalyst powder is a Ni-based alloy catalyst powder with a fineness of 600-1000 mesh; expressed in weight percentage, the Ni-based alloy catalyst powder is made of the following raw materials according to conventional methods: Fe 25%, Co 5%, Ce 2%, Mn 5%, SiC 1%, Mo 1%, the balance is Ni;

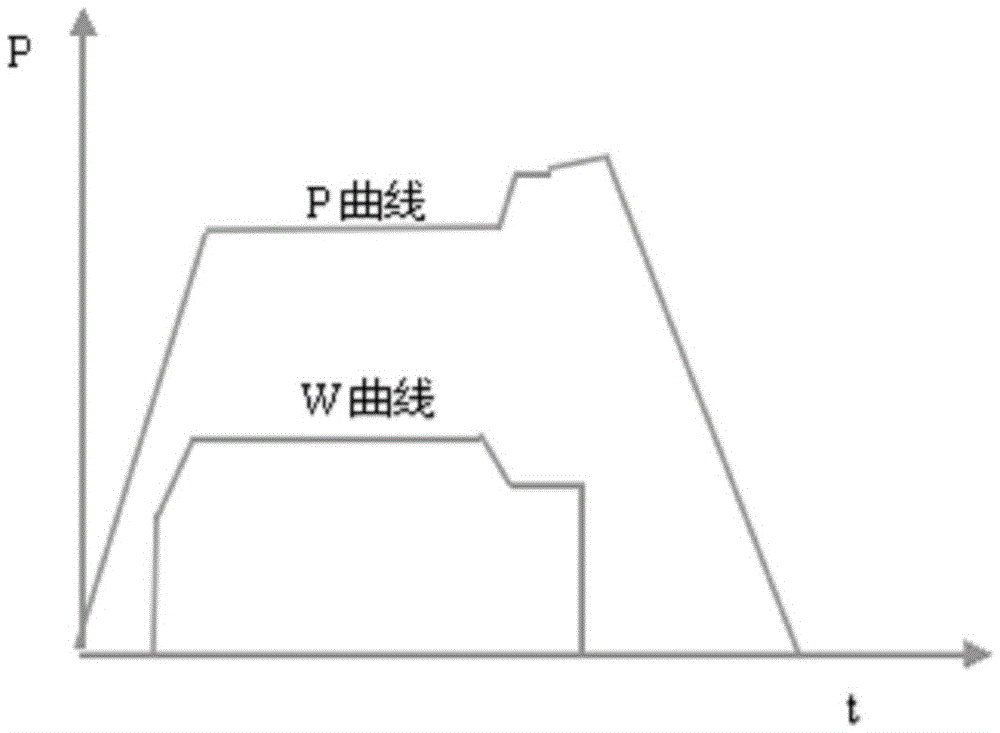

[0035] b. Place the mixed raw material obtained in step a in a three-dimensional mixer for 6 hours, perform isostatic pressing at 230 MPa, and then granulate after the treatment to...

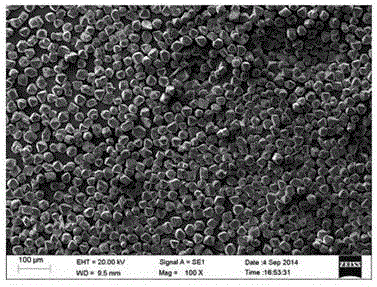

Embodiment 2

[0044] The synthetic method of superfine particle diamond single crystal of the present invention, detailed steps are as follows:

[0045] a. Mixing of graphite powder and catalyst powder: take graphite powder (spherical graphite with an impurity content less than 20ppm, the particle size of graphite powder is 600-1000 mesh) and catalyst powder in a weight ratio of 5:5 and mix them;

[0046] Graphite powder is baked in an oven for 6 hours before use, and the baking temperature is 200°C;

[0047] The catalyst powder is a Ni-based alloy catalyst powder with a fineness of 600-1000 mesh; expressed in weight percentage, the Ni-based alloy catalyst powder is made of the following raw materials according to conventional methods: Fe 20%, Co 3%, Ce0.5%, Mn3%, SiC 0.5%, Mo0.5%, the balance is Ni;

[0048] b. Place the mixed raw material obtained in step a in a three-dimensional mixer for 5 hours, perform isostatic pressing at 240 MPa, and then granulate after the treatment to form a sp...

Embodiment 3

[0057] The synthetic method of superfine particle diamond single crystal of the present invention, detailed steps are as follows:

[0058] a. Mixing of graphite powder and catalyst powder: take graphite powder (spherical graphite with an impurity content less than 20ppm, the particle size of graphite powder is 600-1000 mesh) and catalyst powder according to the weight ratio of 4:6 and mix them;

[0059] Graphite powder is baked in the oven for 4 hours before use, and the baking temperature is 200°C;

[0060] The catalyst powder is a Ni-based alloy catalyst powder with a fineness of 600-1000 mesh; expressed in weight percentage, the Ni-based alloy catalyst powder is made of the following raw materials according to conventional methods: Fe 22%, Co 4%, Ce 1.2%, Mn4%, SiC 0.75%, Mo0.75%, the balance is Ni;

[0061] b. Place the mixed raw material obtained in step a in a three-dimensional mixer for mixing for 6 hours, perform isostatic pressing at 260 MPa, and then granulate after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com