Manufacturing method for hierarchical pore metal fiber sintered plate

A metal fiber and manufacturing method technology, applied in the field of composite metal, can solve the problems of high equipment dependence, difficult processing and manufacturing, long production cycle, etc., and achieve the effects of broad application prospects, fast connection speed, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, copper is used as the first metal to make fibers, and aluminum is used as the second metal to make the middle layer aluminum foil. The manufacture of copper fiber can be processed on an ordinary lathe by turning copper rods with special multi-tooth tools. The surface roughness of the metal fiber processed by this method is appropriate, and the equivalent diameter is 50-100 μm. In particular, the copper fiber of 50 μm is used in this embodiment. Next, the copper fiber is cut into appropriate small sections with a length of about 10-20 mm, especially, 10 mm is used in this embodiment. Copper fibers are pressed into copper fiber sheets with a predetermined porosity.

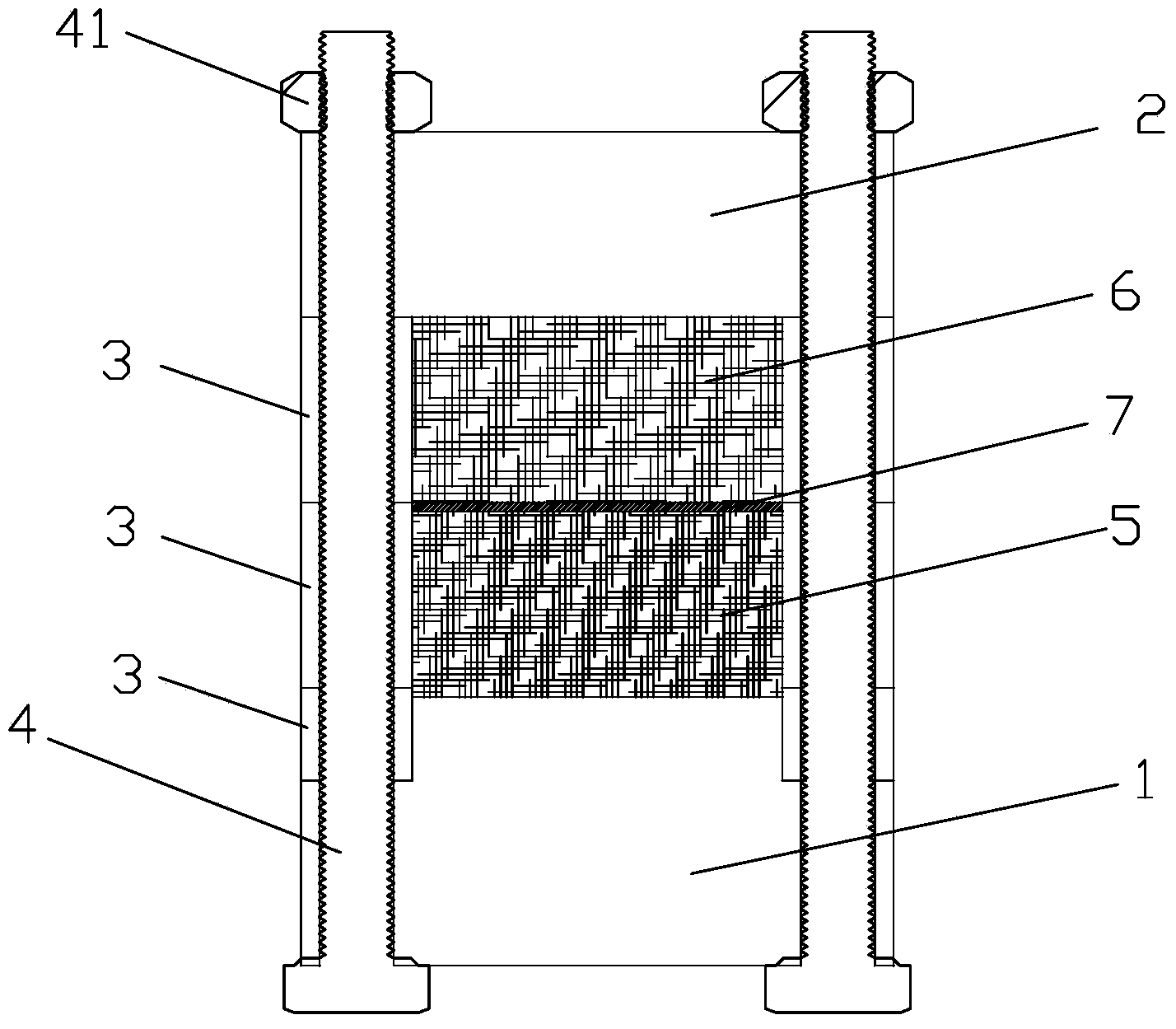

[0026] The present invention designs and manufactures a special mold for metal fiber sintered plates, and its structural schematic diagram is as follows figure 1 shown. The mold is composed of a bottom plate 1, a pressing plate 2, a plurality of gaskets 3 of different thicknesses, bolts...

Embodiment 2

[0031] In this embodiment, aluminum is used as the first metal, tin is used as the second metal, and the structure of the mold is the same as that of Embodiment 1. Aluminum fibers with a length of 10-20 mm and a diameter of 75 μm are made of aluminum. According to the relationship between mass and porosity, a certain mass of aluminum fiber is weighed and pre-pressed by a mold to form a fiberboard with a predetermined porosity, and the thickness range is 5-100mm. The relationship between porosity and mass is E=1-m / (ρV), where E is porosity, m is the mass of aluminum fiber, ρ is the density of aluminum, and V is the volume of aluminum fiberboard. Make two aluminum fiber boards with a porosity of 85% and 98% respectively, cut the tin foil with a thickness of less than 0.1mm into the middle layer of the corresponding size of the aluminum fiber board, place it between the two aluminum fiber boards to form a laminated structure, and place it in the mold suppress. The mold is put i...

Embodiment 3

[0033]In this embodiment, stainless steel is used as the first metal, manganese is used as the second metal, and the structure of the mold is the same as that of Embodiment 1. Stainless steel fibers with a length of 10-20 mm and a diameter of 100 μm are made of stainless steel. According to the relationship between mass and porosity, a certain mass of stainless steel fibers is weighed and pre-pressed by a mold to form a fiberboard with a predetermined porosity, and the thickness range is 5-100mm. The relationship between porosity and mass is E=1-m / (ρV), where E is porosity, m is the mass of stainless steel fiber, ρ is the density of stainless steel aluminum, and V is the volume of stainless steel fiber plate. Two stainless steel fiber plates with a porosity of 60% and 70% were made, and the manganese foil with a thickness of less than 0.1 mm was cut into an intermediate layer of the corresponding size as the stainless steel fiber plate and placed between the two stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com