Lignin-based grafted modified porous adsorbing material and preparation method thereof

A porous adsorption material, graft modification technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of molecular weight polydispersity, limited large-scale application, complex structure, etc. The effect of improving molecular weight, simple process and good material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

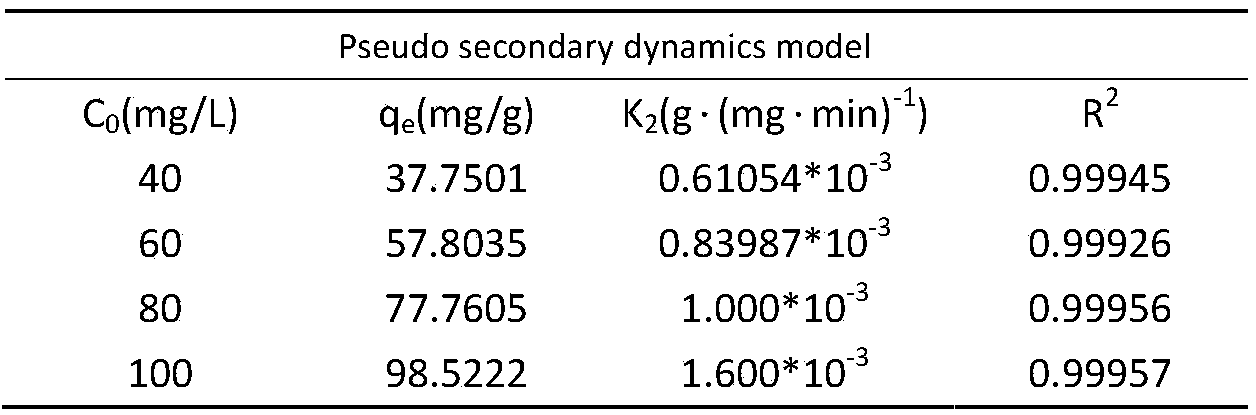

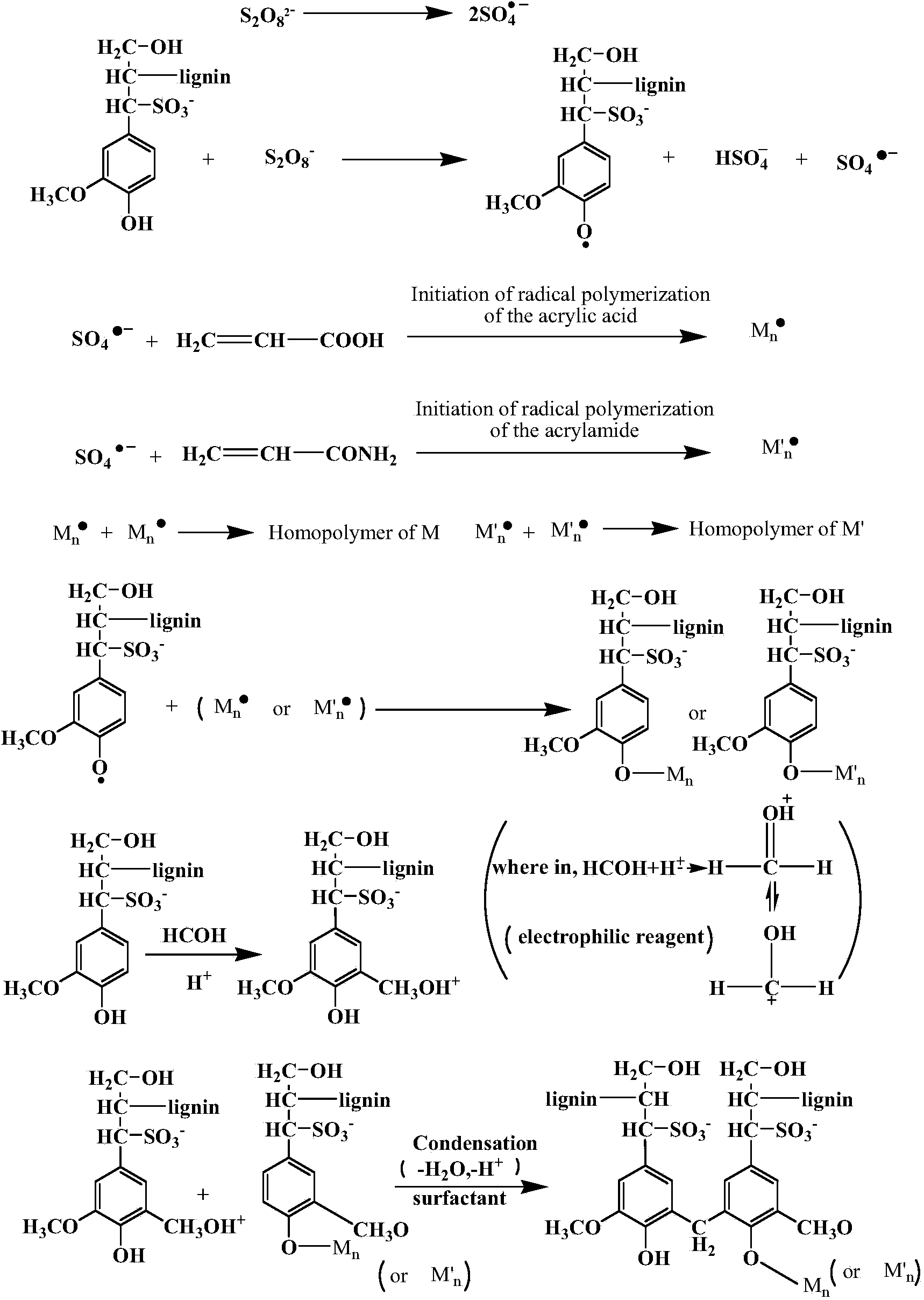

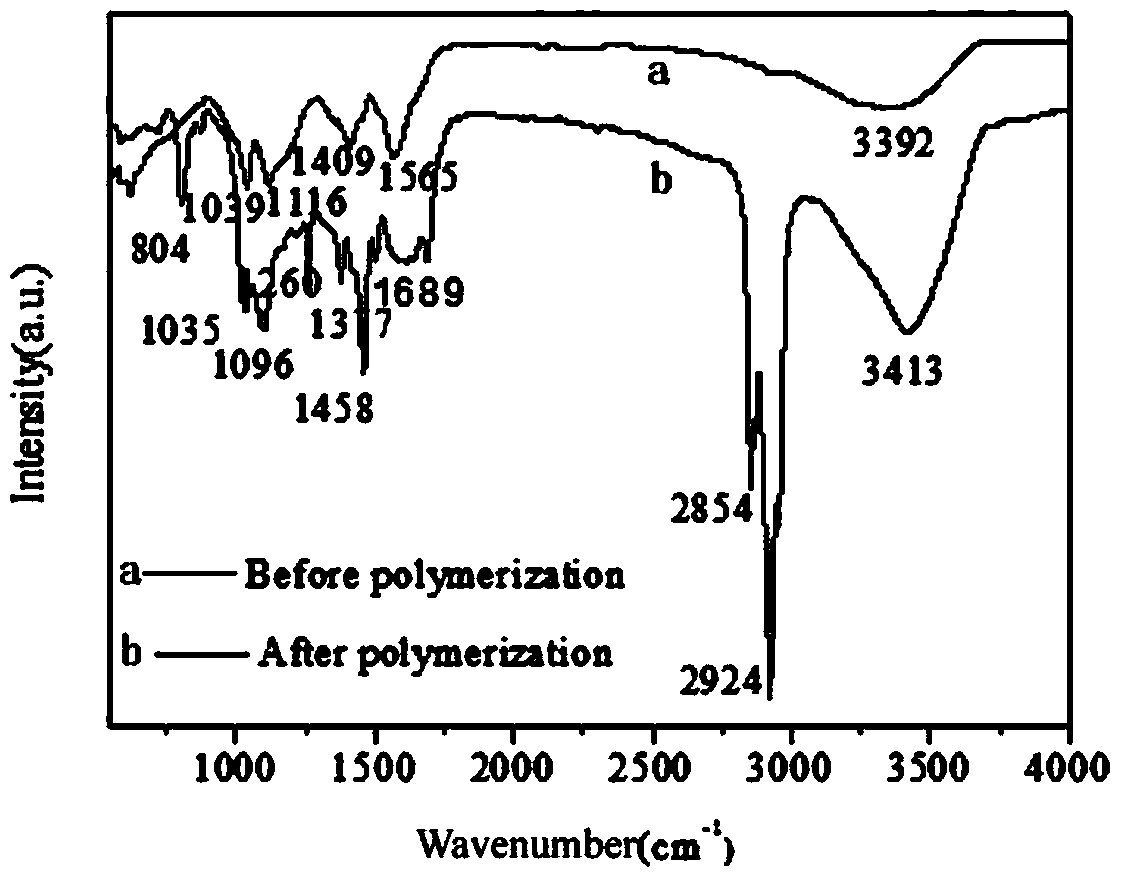

[0033] Weigh 4.000g sodium lignosulfonate and 4.000g acrylamide and dissolve in 150ml water, take 8ml acrylic acid and add it to the solution, adjust the pH of the solution to 8.0, seal it, heat up to 80°C and add 0.05g potassium persulfate for 6 hours After cooling to room temperature, the grafted lignosulfonate grafted product was obtained. Take 100ml of liquid paraffin, add 5ml of concentrated hydrochloric acid and 10ml of formaldehyde, and add 1ml of Tween 80, heat up to 80°C, slowly add the above-mentioned grafted lignosulfonate grafted product under stirring conditions, and stop for 5 hours reaction. After opening and heating to 105°C to remove small molecular substances, pass the obtained product through a 60-100 mesh sieve, and fully wash (with acetone, acid solution, lye solution, and distilled water in sequence), and freeze-dry. The quality of the obtained product is 0.0756g . And keep the final product sealed.

Embodiment 2

[0035] Weigh 4.000g of sodium lignosulfonate and 4.000g of acrylamide and dissolve them in 150ml of water, take 8ml of acrylic acid and add it to the solution, adjust the pH of the solution to 8.0, seal it, and add 0.1g of potassium persulfate after heating up to 80°C for 6 hours After cooling to room temperature, the grafted lignosulfonate grafted product was obtained. Take 150ml of liquid paraffin, add 5ml of concentrated hydrochloric acid and 15ml of formaldehyde, and add 2ml of Tween 80, heat up to 80°C, slowly add the above-mentioned grafted lignosulfonate grafted product under stirring conditions, and stop for 5 hours reaction. After opening and heating to 105°C to remove small molecular substances, pass the obtained product through a 60-100 mesh sieve, and fully wash (with acetone, acid solution, lye solution, and distilled water in sequence), and freeze-dry. The quality of the obtained product is 0.129g . And keep the final product sealed.

Embodiment 3

[0037] Weigh 4.000g sodium lignosulfonate and 4.000g acrylamide and dissolve in 150ml water, take 8ml acrylic acid and add it into the solution, adjust the pH of the solution to 8.0, seal it, heat up to 80°C and add 0.15g potassium persulfate for 6 hours After cooling to room temperature, the grafted lignosulfonate grafted product was obtained. Take 200ml of liquid paraffin, add 5ml of concentrated hydrochloric acid and 20ml of formaldehyde, and add 3ml of Tween 80, heat up to 80°C, slowly add the above-mentioned grafted lignosulfonate grafted product under stirring conditions, and stop for 5 hours reaction. After opening and heating to 105°C to remove small molecular substances, pass the obtained product through a 60-100 mesh sieve, and fully wash (with acetone, acid solution, lye solution, and distilled water in sequence), and freeze-dry. The quality of the obtained product is 0.208g . And keep the final product sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com