Polycarbonate-containing styrene thermoplastic elastomer composite material, and preparation method of formed body made of composite material

A technology of thermoplastic elastomer and styrene type, which is applied in the field of preparation of styrene type thermoplastic elastic composite materials and their moldings, can solve the problems of high price, poor processability, stress cracking, etc., and achieve dimensional stability and excellent tensile strength and tear strength, the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

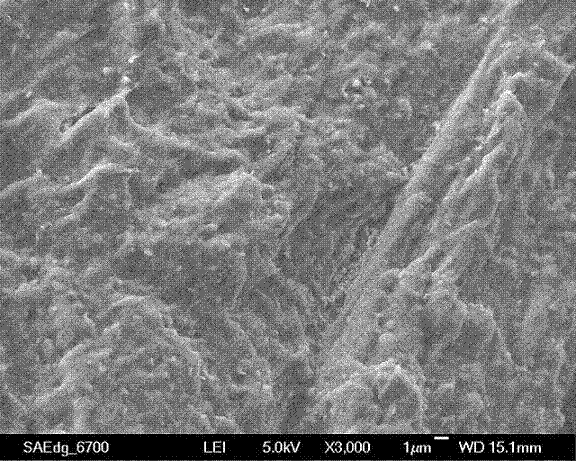

Image

Examples

Embodiment 1

[0019] In this embodiment, the styrene-type thermoplastic elastomer composite material containing polycarbonate is made up of following components: 10kg styrene-type thermoplastic elastomer SBS (YH 815), 2.5kg carbonate / acrylonitrile-butadiene-benzene Ethylene copolymer alloy (PC / ABS), 0.3kg methacrylic acid-butadiene-styrene copolymer (MBS), 4kg white mineral oil, 30g light and heat stabilizer 1076, 100g zinc stearate, the above components The materials are pre-mixed in a high-speed mixer for 8 minutes, and then the pre-mixed material is passed through a twin-screw extruder, melted and extruded at 190 degrees, cooled and granulated, and then molded by injection molding to obtain a molded shoe sole.

[0020] The thermoplastic elastomer sole that above-mentioned preparation obtains is milky white, density 0.91g / cm 3 , DIN wear-resistant 60 cm 3 , Dimensional shrinkage of 0.13%, tear strength of 18N / mm, elongation at break of 224%, low temperature (-30 degrees) folding resistan...

Embodiment 2

[0022] In this embodiment, the polycarbonate-containing styrene-type thermoplastic elastomer composite material is made up of the following components: 10kg styrene-type thermoplastic elastomer SBS (YH 815), 2.5kg polycarbonate / polystyrene alloy (PC / PS), 0.3kg maleic anhydride grafted SBS (SBS-g-MAH), 4kg white mineral oil, 30g light and heat stabilizer B1004, 100g ethylene bis stearamide (EBS), the above component materials were mixed at high speed Premixed in the machine for 8 minutes, then the premixed material is passed through a twin-screw extruder, melted and extruded at 190 degrees, cooled and granulated, and then injection molded to obtain a molded body.

[0023] The thermoplastic elastomer molded body prepared above is milky white and has a density of 0.90 g / cm 3 , DIN wear-resistant 67 cm 3 , Dimensional shrinkage 0.18%, tear strength 17N / mm, elongation at break 213%, low temperature (-30 degrees) 150,000 times of folding without cracks.

Embodiment 3

[0025] In this embodiment, the polycarbonate-containing styrene-type thermoplastic elastomer composite material is composed of the following components: 10kg styrene-type thermoplastic elastomer SEBS (YH 561), 2.5kg PC / ABS alloy, 0.3kg maleic anhydride Branch SEBS (SEBS-g-MAH), 5kg white mineral oil, 30g light heat stabilizer 1076, 100g zinc stearate, premix the above component materials in a high-speed mixer for 8 minutes, then pass the premix through double Screw extruder, melt extrusion at 200 degrees, cool and granulate, and then use injection molding to obtain a molded body.

[0026] The thermoplastic elastomer molded body prepared above has a density of 0.93g / cm 3 , DIN wear-resistant 69 cm 3 , Dimensional shrinkage of 0.18%, tear strength of 18N / mm, elongation at break of 209%, low temperature (-30 degrees) folding resistance of 150,000 times without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Wear-resistant | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com