Single crystal copper-silver composite conductor and preparation method thereof

A technology of composite wire and single crystal copper, which is applied in the direction of single crystal growth, metal/alloy conductor, cable/conductor manufacturing, etc., can solve the problem of high conductivity, flexibility and signal fidelity, copper wire conductivity and Flexibility is difficult to meet the requirements, pure silver wire is expensive and other problems, to achieve the effect of improving electrical conductivity and signal transmission performance, reducing electron scattering, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

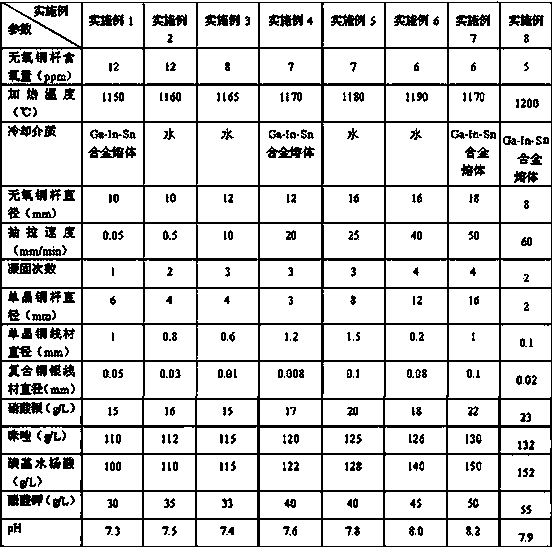

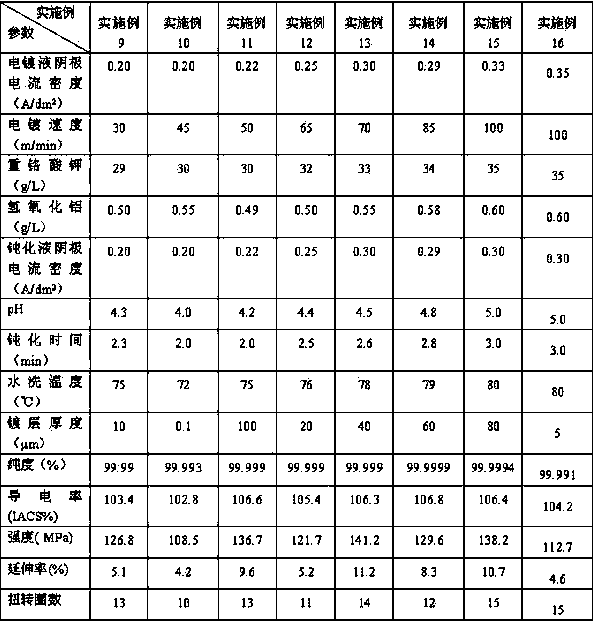

[0015] A method for preparing a single-crystal copper-silver composite wire, the method comprising the following steps: ① Preparation of a single-crystal copper wire: heating an oxygen-free copper rod, and after the oxygen-free copper rod is partially melted, the partially melted oxygen-free copper The rod is pulled and directional solidified to obtain a single crystal copper rod, and the single crystal copper rod is drawn into a single crystal copper wire; Water washing-alkali washing-the second washing-acid washing-the third washing and then enter the electroplating tank; ③Preparation of single crystal copper-silver composite wire: use cyanide-free silver plating process to silver-plate the surface of single-crystal copper wire; The final single crystal copper-silver composite wire is drawn into single crystal copper-silver composite wire; ④ Preparation of single crystal copper-silver composite wire: use electrochemical passivation method to generate a layer of corrosion-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com