Construction method and applications of antibacterial bionic silicification collagen scaffold material

A technology of scaffold material and silicified collagen, applied in medical science, prosthesis, etc., can solve the problems of partial degradation of collagen, long cycle, limited calcification depth, etc., to improve mechanical properties, good mechanical properties, and promote adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

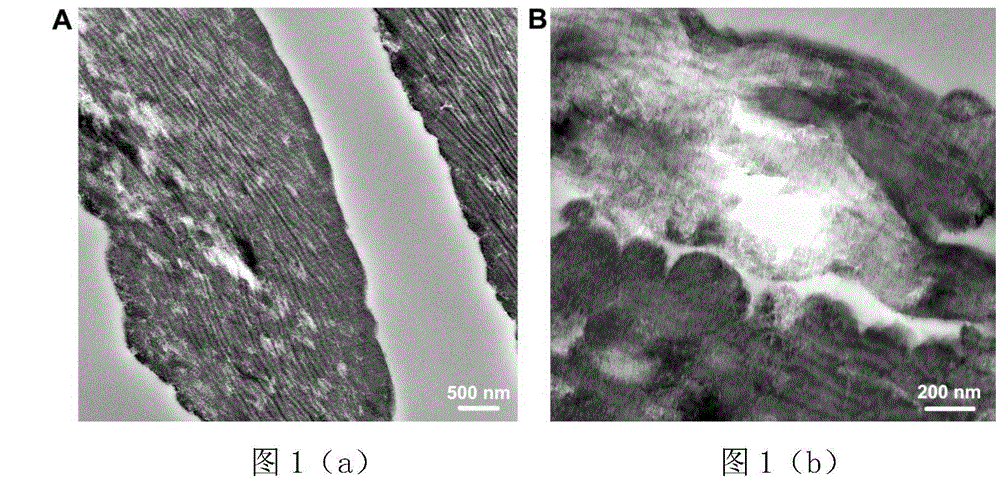

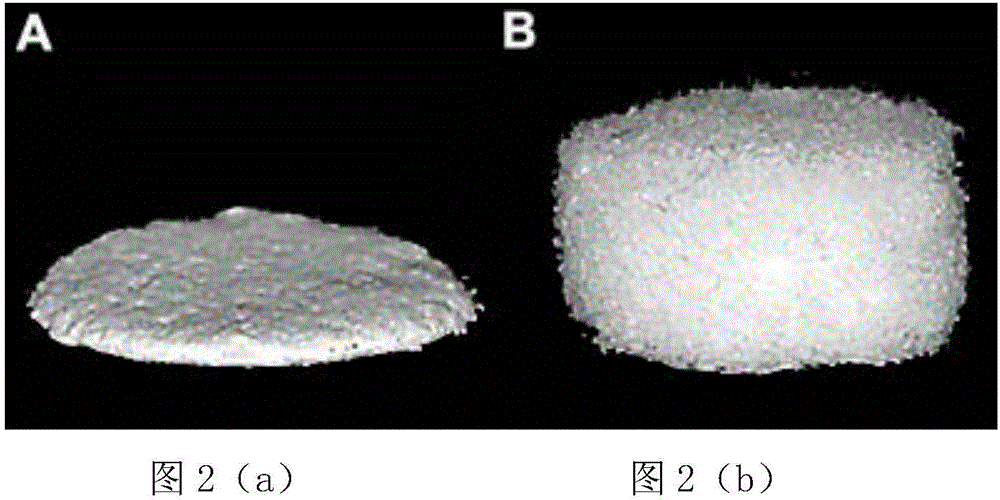

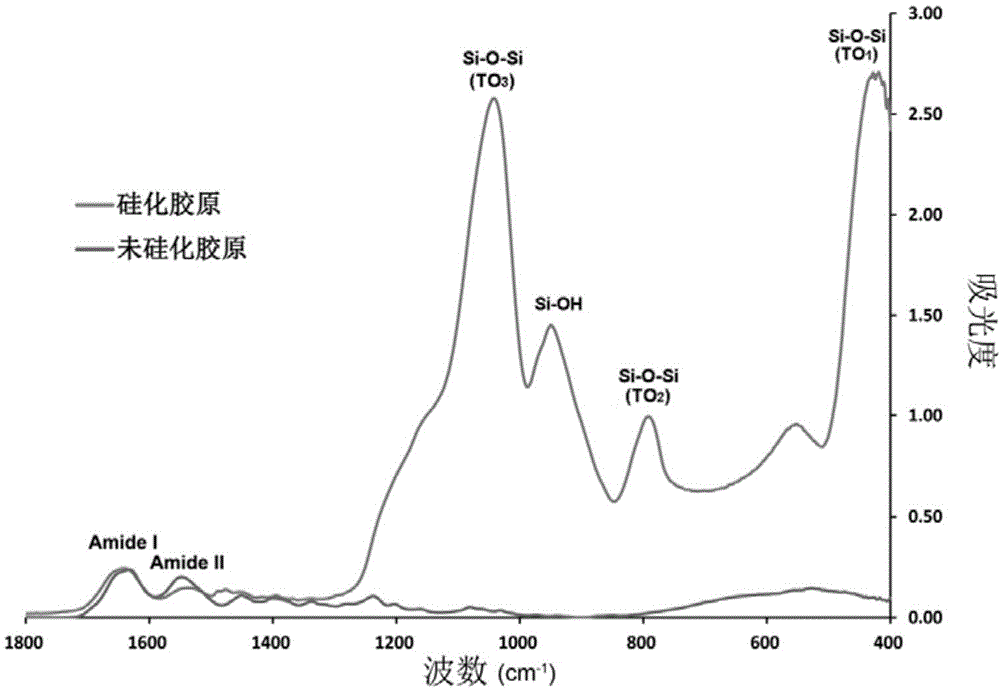

[0041] The antibacterial biomimetic silicified collagen scaffold material construction method of this embodiment, according to the following steps:

[0042] (1) Preparation of collagen sponge scaffold: Take 500g of fresh bovine tendon, remove fascia, fat and other impurities and cut into thin slices; add the cut tendon slices to 250mL of 0.5% protease digestion solution, and digest at a constant temperature of 37°C After 3 hours of treatment, use 100mL0.3g / L H 2 o 2The solution terminates the enzyme digestion reaction, rinses repeatedly with distilled water and then air-dries; add 100mL of 0.1% acetic acid solution to 100g of dried tendons to swell, stir evenly and centrifuge to remove impurities; use phosphate solution for repeated salting-out to improve collagen The purity of the solution; use polyethylene glycol to concentrate to prepare a collagen solution with a final concentration of 20 mg / mL; after pre-cooling at -20°C for 2 hours, freeze-dry in a positive air freeze d...

Embodiment 2

[0061] This embodiment differs from Embodiment 1 in that:

[0062] (3) Tetraethyl orthosilicate is used as raw material at room temperature to prepare orthosilicic acid with a concentration of 5% by dilute acid hydrolysis; the obtained orthosilicic acid and 6% chlorhexidine gluconate are uniformly Mix and adjust the pH value of the final solution to 5.5; centrifuge at 3000 rpm for 3 minutes, and take the supernatant to obtain a 2.5% orthosilicate precursor solution stabilized with 3% chlorhexidine gluconate.

[0063] (4) Place the surface-treated collagen scaffold obtained in step (2) in the stable silicic acid precursor solution obtained in step (3) for mineralization treatment, replace the fresh silicic acid precursor solution every day, and incubate for 6 days respectively , rinsed repeatedly with distilled water, freeze-dried for later use, and prepared an antibacterial biomimetic silicified collagen scaffold material.

Embodiment 3

[0065] This embodiment differs from Embodiment 1 in that:

[0066] (3) Tetraethyl orthosilicate is used as raw material at room temperature to prepare orthosilicic acid with a concentration of 8% by dilute acid hydrolysis; the obtained orthosilicic acid and 10% chlorhexidine gluconate are uniformly Mix and adjust the pH value of the final solution to 5.5; centrifuge at 3000 rpm for 3 minutes, and take the supernatant to obtain a 4% orthosilicate precursor solution stabilized with 5% chlorhexidine gluconate.

[0067] (4) Place the surface-treated collagen scaffold obtained in step (2) in the stable silicic acid precursor solution obtained in step (3) for mineralization treatment, replace the fresh silicic acid precursor solution every day, and incubate for 2 days respectively , rinsed repeatedly with distilled water, freeze-dried for later use, and prepared a new type of antibacterial biomimetic siliconized collagen scaffold material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com