Subcritical drum boiler water treatment method

A drum boiler and treatment method technology, applied in the direction of non-polluted water treatment, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problem of difficult to accurately determine the level of salt content in boiler water, concentration of chlorine ions in boiler water, Aggravate problems such as furnace tube corrosion, achieve the effect of avoiding hidden phenomena, cleaning the thermal system, and reducing the salt content of furnace water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for treating subcritical drum boiler furnace water, adopting a one-time uniform feeding mode to add sodium hydroxide to the subcritical drum boiler, so that the concentration of sodium hydroxide in the boiler water is 0.5% by weight, Keep the furnace water running while adding the sodium hydroxide. The pH of the furnace water before sodium hydroxide is added to the furnace water is 9.2 to 9.25, and the pH of the furnace water after adding sodium hydroxide is 9.45 to 9.5.

Embodiment 2

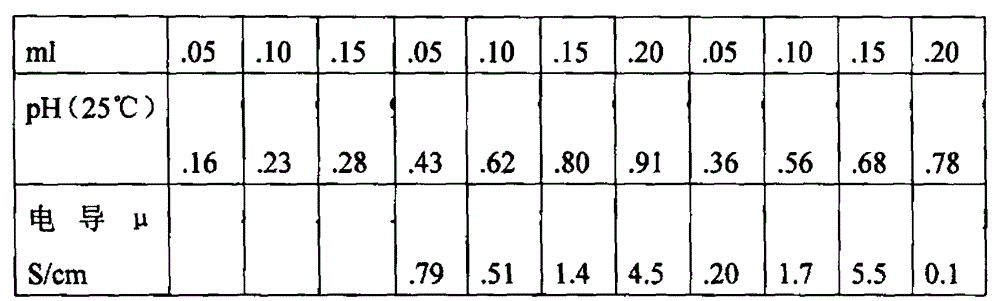

[0020] A method for treating subcritical steam drum boiler furnace water, which adopts a one-time uniform feeding mode to add sodium hydroxide to the subcritical steam drum boiler, so that the concentration of sodium hydroxide in the boiler water is 0.05% and 0.05% by weight. 0.08%, keep the furnace water running normally when adding sodium hydroxide. The pH of the furnace water before sodium hydroxide is added to the furnace water is 9.2 to 9.25, and the pH of the furnace water after adding sodium hydroxide is 9.45 to 9.5.

[0021] Add trisodium phosphate to furnace water in the same manner, so that the concentration of sodium hydroxide in furnace water is 0.5% by weight. The pH of the test water sample is 9.09, the conductance is 3.4 μS / cm, the water sample volume is 100ml during the test, and the comparison test of the influence of sodium hydroxide and phosphate addition on the boiler water quality is shown in Table 1.

[0022] Table 1 Sodium hydroxide, phosphate comparati...

Embodiment 3

[0028] A method for treating subcritical steam drum boiler furnace water, adopting the mode of one-time uniform dosing to add sodium hydroxide to the subcritical steam drum boiler, so that the concentration of sodium hydroxide in the boiler water is 1% by weight percentage, Keep the furnace water running while adding the sodium hydroxide. The pH of the furnace water before sodium hydroxide is added to the furnace water is 9.2 to 9.25, and the pH of the furnace water after adding sodium hydroxide is 9.45 to 9.5.

[0029] In this example, the boiler water of No. 2 unit of Waigaoqiao Power Plant is treated with sodium hydroxide, and the quality of the boiler water is stable, and all indicators meet the third part of the steam-water chemistry guidelines for thermal power plants: drum boiler boiler water sodium hydroxide treatment ( DL / T805.3-2004) furnace water quality standard.

[0030] Sodium hydroxide treatment of furnace water eliminates the "temporary disappearance" phenomen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com