Preparation method of C/C composite material

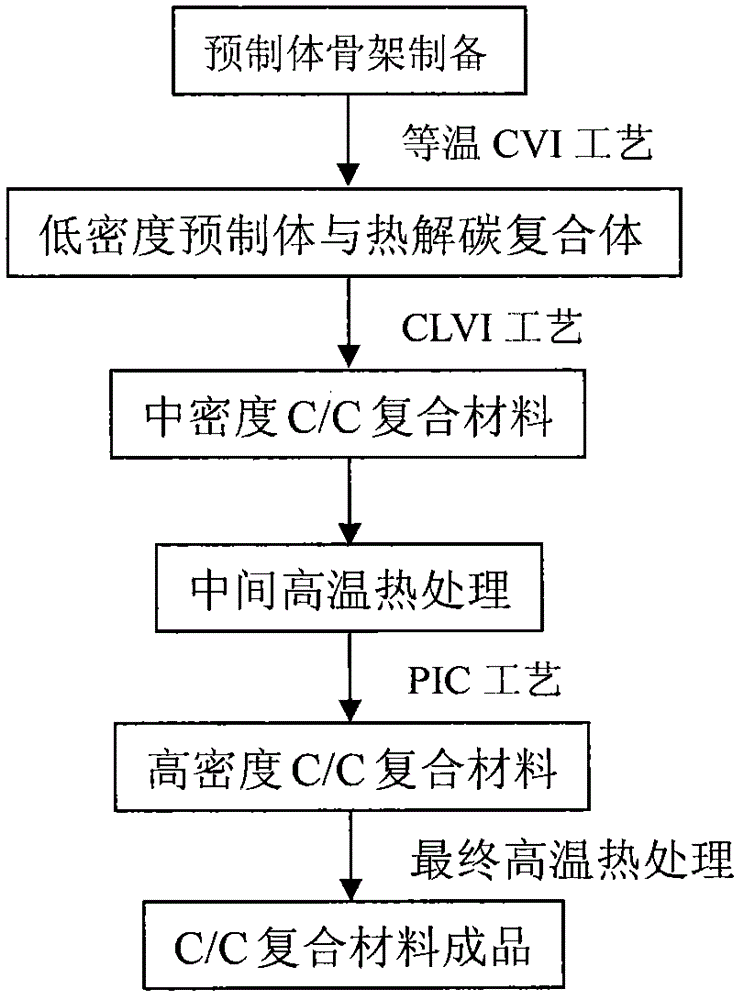

A carbon composite material and composite material technology, which is applied in the field of carbon/carbon composite material preparation, can solve the problems of poor bonding between fiber and matrix interface, low utilization rate of raw materials, long preparation period, etc., so as to shorten the preparation period and improve production. Efficiency and raw material utilization, effect of short deposition cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Use 6K carbon fiber with the brand name T300 as the reinforcement of the composite material, and use the three-dimensional four-way weaving method to weave into a block three-dimensional weaving prefabricated body. The carbon fiber density of the prefabricated body is 0.78g / cm 3 . The size of the prefabricated body is 100mm*100mm*100mm.

[0033] 2) Put the preform into a chemical vapor deposition furnace to infiltrate the carbon substrate, the infiltration temperature is 900°C, the furnace pressure is 150Pa, the flow rate of propylene gas is 35ml / min, the flow rate of diluent gas argon is 300ml / min, and the deposition time is 60h. The resulting density is 1.12g / cm 3 preforms and pyrolytic carbon composites.

[0034] 3) Put the low-density prefabricated body and pyrolytic carbon composite obtained in step 2 into the chemical liquid phase gasification infiltration equipment to infiltrate the carbon matrix. The liquid precursor is kerosene, and nitrogen with a flow ra...

Embodiment 2

[0039] 1) Use T700 12K carbon fiber and T700 short carbon fiber mesh tire as the composite material reinforcement, and use the relay-type acupuncture method to make a hollow cylindrical three-dimensional needle-punched felt prefabricated body, and the needle-punched density is 35-40 needles / cm 2 . The prepared preform density is 0.45g / cm 3 . The specifications of the prefabricated body are 200mm in outer diameter, 80mm in inner diameter, and 200mm in height.

[0040] 2) Put the prefabricated body into a chemical vapor deposition furnace to infiltrate the carbon matrix, the infiltration temperature is 950°C, the furnace pressure is 10kPa, the flow rate of propylene gas is 3L / min, the flow rate of diluent gas argon is 5L / min, and the deposition time is 120h. The resulting density is 0.94g / cm 3 preforms and pyrolytic carbon composites.

[0041] 3) Put the low-density prefabricated body and pyrolytic carbon composite obtained in step 2 into the chemical liquid phase gasificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com