Preparation method of pyrethroid pesticide type molecularly imprinted membrane

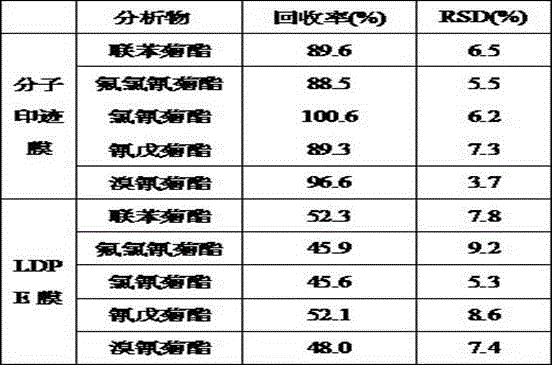

A pyrethroid, molecularly imprinted membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of permeability, high anti-pollution ability, and great promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

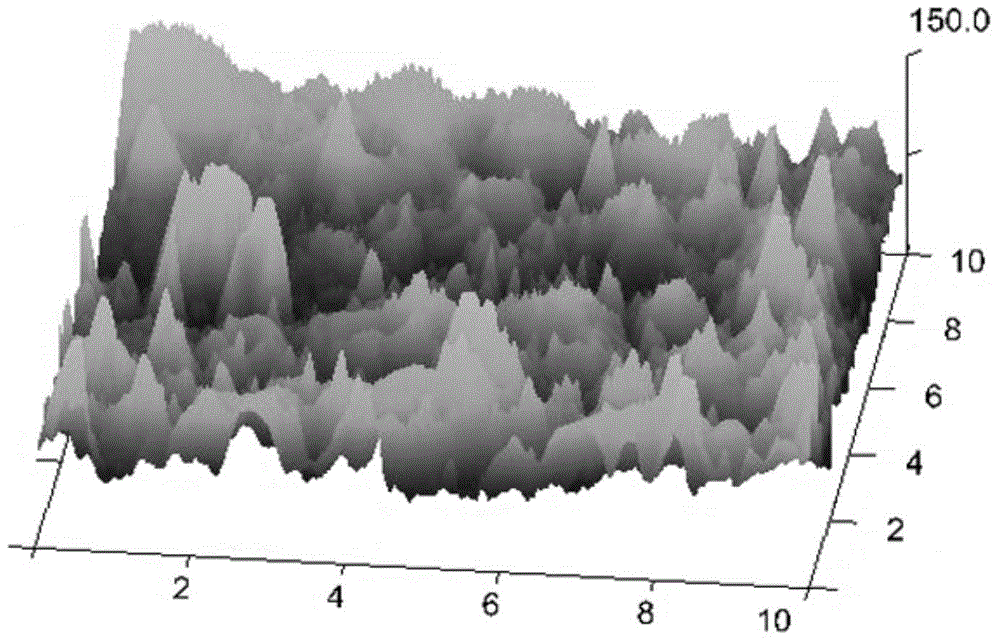

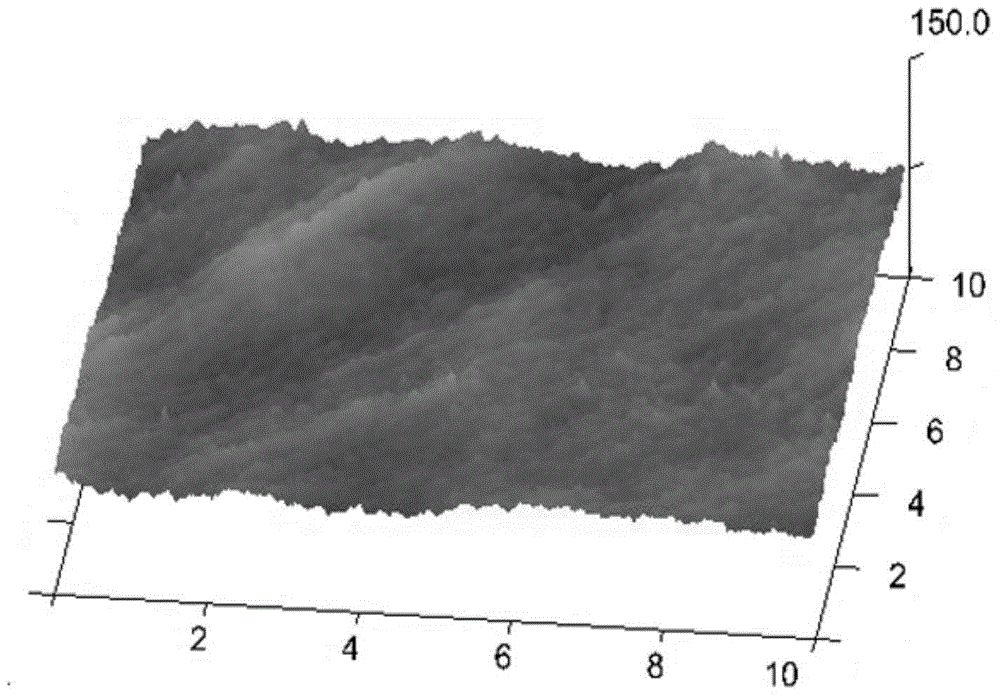

Image

Examples

Embodiment 1

[0024] A method for preparing a pyrethroid pesticide molecularly imprinted membrane, the specific steps are as follows:

[0025] (1) Clean the low-density polyethylene (LDPE) film bag sequentially with absolute ethanol, acetone and distilled water ultrasonically, each time for 8 minutes, and vacuum dry it in a vacuum oven at 45°C for 12 hours; the dried LDPE film bag Placed in the reaction chamber of the plasma processor, after passing through Ar, under the conditions of 25 Pa and 45 W, treat for 30 s to activate the surface of the LDPE film bag, wherein the thickness of the LDPE film bag is 0.02-0.05 mm, and the density is 0.915~0.940 g / cm 3 ;

[0026] (2) Mix the template molecule cypermethrin, the functional monomer methacrylic acid and the crosslinking agent ethylene glycol dimethacrylate at a molar ratio of 1:2:25 to obtain a mixture, and add the mixture to the acetonitrile / acetone mixture (9 : 1, v / v), nitrogen was introduced, and ultrasonic degassed for 14 min to obta...

Embodiment 2

[0031] A method for preparing a pyrethroid pesticide molecularly imprinted membrane, the specific steps are as follows:

[0032] (1) Clean the LDPE film bag sequentially with absolute ethanol, acetone and distilled water ultrasonically, each time for 8 minutes, and dry it in a vacuum oven at 50°C for 8 hours; place the dried LDPE film bag in plasma treatment In the reaction chamber of the instrument, after being fed with Ar, the surface of the LDPE film bag was activated under the conditions of 45 Pa and 30 w for 120 s. The thickness of the LDPE film bag was 0.02-0.05 mm, and the density was 0.915-0.940 g / cm 3 ;

[0033] (2) Mix deltamethrin, acrylic acid AA and ethylene glycol dimethacrylate EGDMA at a molar ratio of 1:8:25 to obtain a mixture, and add the mixture to the acetonitrile / acetone mixture (9:1, After v / v), nitrogen gas was introduced, and ultrasonic degassing was carried out for 16 min to obtain a grafting solution;

[0034](3) Immerse the surface-activated LDP...

Embodiment 3

[0036] A method for preparing a pyrethroid pesticide molecularly imprinted membrane, the specific steps are as follows:

[0037] (1) Clean the LDPE film bag sequentially with absolute ethanol, acetone and distilled water ultrasonically, each time for 10 min, and dry it in a vacuum oven at 48°C for 10 h; place the dried LDPE film bag in plasma treatment In the reaction chamber of the instrument, after He was introduced, the surface of the LDPE film bag was activated under the conditions of 30 Pa and 40 W for 90 s, and the thickness of the LDPE film bag was 0.02-0.05 mm, and the density was 0.915-0.940 g / cm 3 ;

[0038] (2) Mix bifenthrin, acrylamide (AM) and trimethylolpropane trimethacrylate (TRIM) at a molar ratio of 1:4:25 to obtain a mixture, and add the mixture to acetonitrile / acetone to mix After being immersed in the solution (9:1, v / v), nitrogen gas was introduced, and ultrasonic degassing was carried out for 15 min to obtain the grafting solution;

[0039] (3) Imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com