Preparation method of ITO thin film

A thin film and solution technology, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, electrical components, etc., can solve the problems of difficult control of doping amount, complicated operation, high resistivity, etc., and achieve easy control of doping amount, The preparation method is simple and the particles are dense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention provides a preparation method of an ITO thin film, and the preparation method is described in figure 1 shown. The preparation method of the ITO film comprises the following steps:

[0024] S01. Preparation of ITO sol: dissolve indium chloride in acetylacetone, stir and heat to obtain indium chloride solution, and then dissolve stannous chloride in absolute ethanol to obtain stannous chloride solution. After the indium chloride solution and the stannous chloride solution are mixed and stirred, a mixed solution containing indium chloride and stannous chloride is obtained, and then a stabilizer and a surfactant are added for aging treatment to obtain an ITO sol;

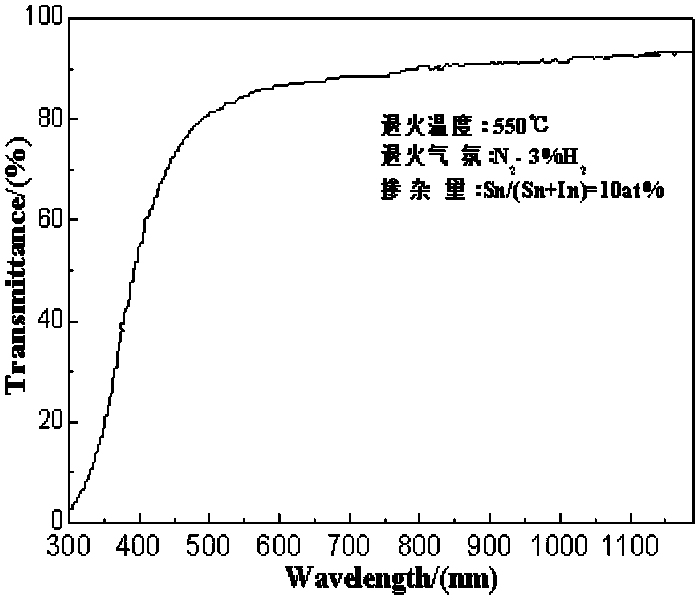

[0025] S02. Preparation of ITO thin film: the ITO solution is subjected to high temperature preheating treatment after pulling the coating film at least once on the substrate, and then annealing treatment is performed to obtain an ITO thin film, wherein the method of the h...

Embodiment 1

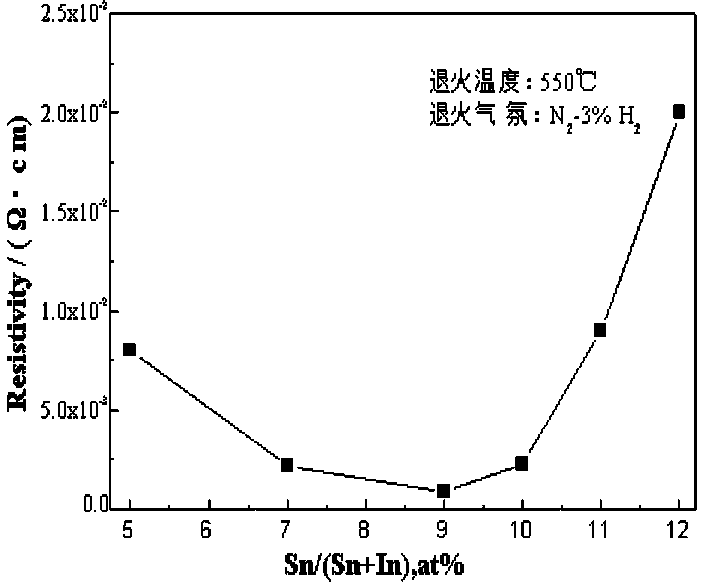

[0044] (1) Preparation of ITO sol: Dissolve indium chloride in acetylacetone at 55°C and heat under reflux for 2 hours, dissolve stannous chloride dihydrate in a small amount of absolute ethanol, and then mix and stir the two solutions at room temperature. Sn / (Sn+In)=5%, add stabilizer and corresponding surfactant, continue to stir for 2h, and obtain ITO sol after aging for 5h;

[0045] (2) Matrix treatment: first, ultrasonically clean the quartz glass for 30 minutes, rinse it with deionized water several times, then put it into acetone to cook for 15 minutes, and finally rinse it with methanol and deionized water in sequence, and then dry it in an oven at 70°C with nitrogen blowing;

[0046] (3) Pulling the coating film: ITO thin film was prepared by dipping and pulling technique, the quartz glass substrate was immersed in the gel vertically for 2 minutes, and then pulled at a uniform speed of 5cm / min to obtain a uniform gel film;

[0047] (4) Heat treatment: The gel film obt...

Embodiment 2

[0050] (1) Preparation of ITO sol: Dissolve indium chloride in acetylacetone at 60°C and heat under reflux for 2 hours, dissolve stannous chloride dihydrate in a small amount of absolute ethanol, and then mix and stir the two solutions at room temperature. / (Sn+In)=10%, add stabilizer and corresponding surfactant, continue to stir for 2h, and get ITO sol after aging for 5h;

[0051] (2) Matrix treatment: first, ultrasonically clean the quartz glass for 30 minutes, rinse it with deionized water several times, then put it into acetone to cook for 15 minutes, and finally rinse it with methanol and deionized water in sequence, and then dry it in an oven at 70°C with nitrogen blowing;

[0052] (3) Pulling the coating film: The ITO film was prepared by dipping and pulling technology, the quartz glass substrate was immersed in the gel vertically for 2 minutes, and the uniform sol film was obtained by pulling at a uniform speed of 10cm / min;

[0053] (4) Heat treatment: The gel film ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

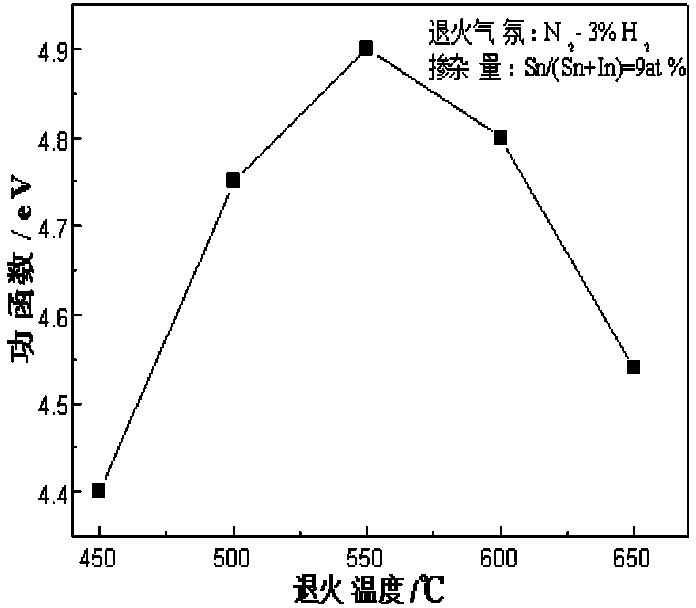

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com