Method for pre-burying of negative electrode of hybrid super capacitor

A supercapacitor and pre-intercalated lithium technology, which is applied in the field of electrochemical energy, can solve the problems of large attenuation of electrolyte concentration, and achieve the effects of saving formation time, safe technical means, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

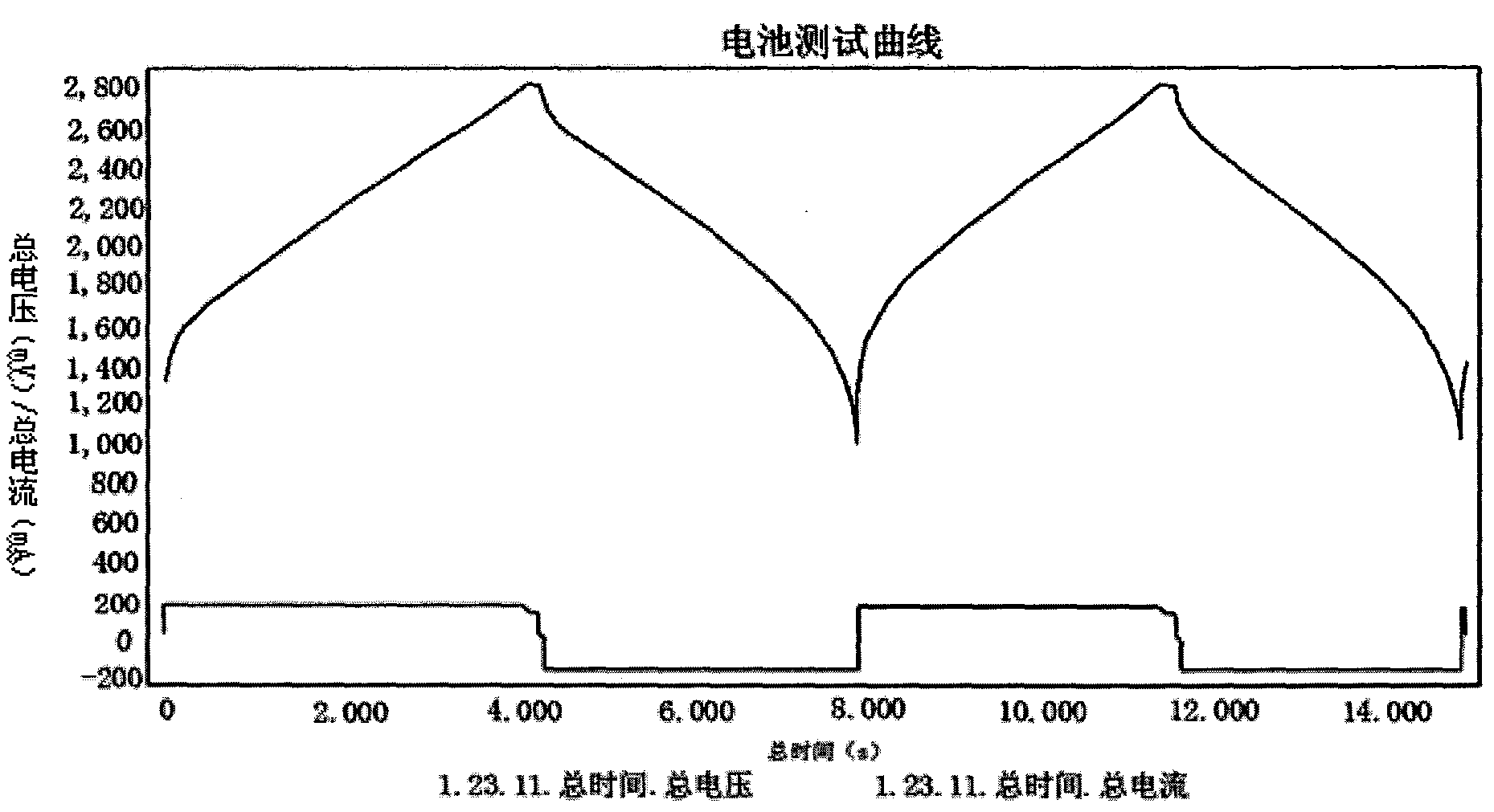

[0027] Activated carbon is used as the positive electrode active material, lithium titanate is used as the negative electrode active material, and the TF4035 diaphragm developed by NKK Company is used as the diaphragm of the lithium-ion supercapacitor. The electrolyte uses 1.2M lithium perchlorate as the main solute, organic borate lithium as the auxiliary solute, ethylene carbonate, dimethyl carbonate, and methyl ethyl carbonate as the solvent, and the film-forming additive is vinylene carbonate , 1,3 propane sultone, control the surface density of the positive and negative electrodes, make the mass ratio of the positive and negative active materials 3.5:1, separate the positive and negative plates with a diaphragm and combine them into a battery cell in a laminated manner, and then charge The positive and negative poles of the core are welded with lugs and glued, and the battery core is shaped by hot and cold pressing; then put into an aluminum-plastic film shell, top-sealed,...

Embodiment 2

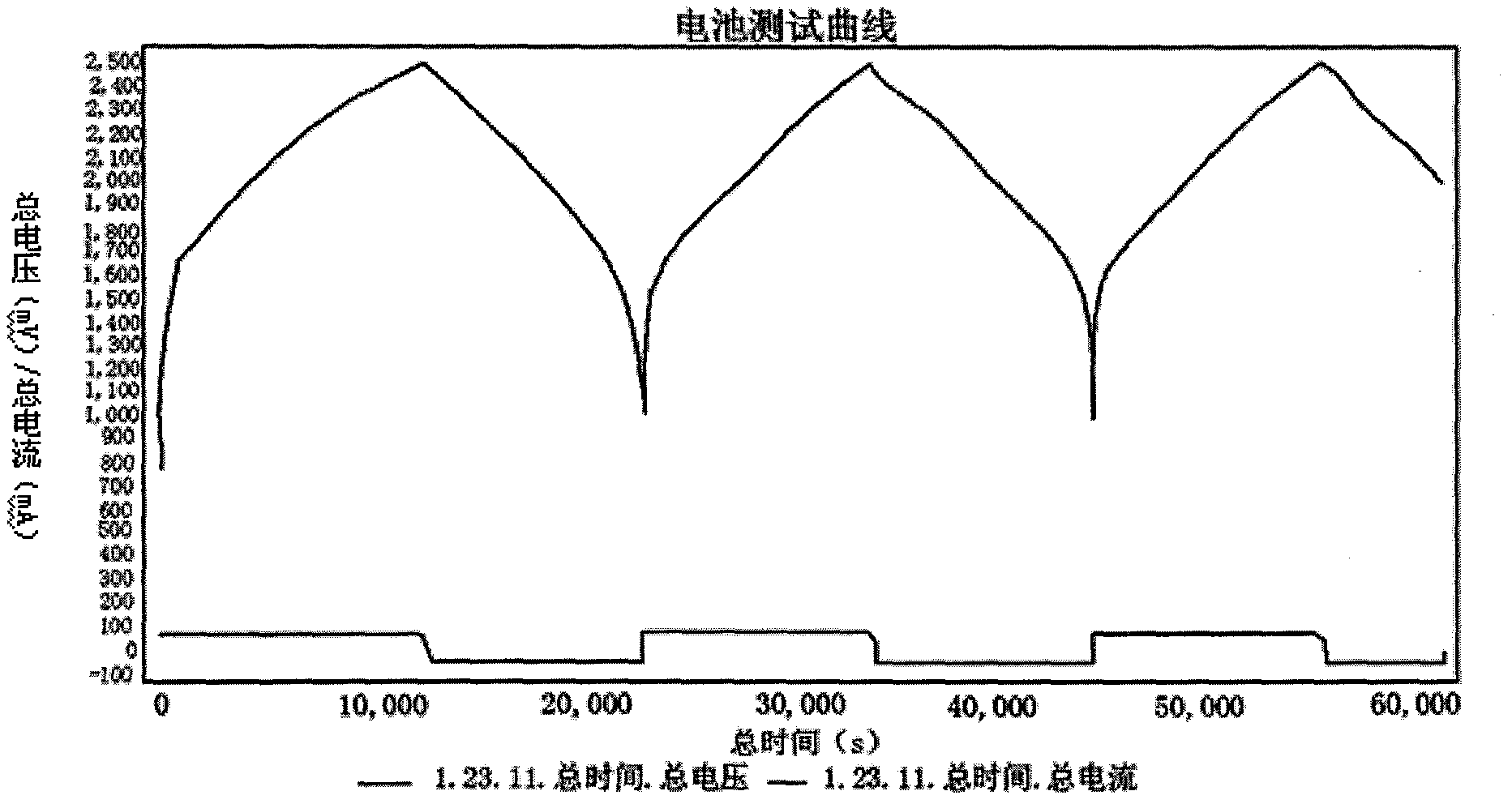

[0029]Activated carbon is used as the positive electrode active material, graphite is used as the negative electrode active material, single-layer PP, single-layer PE, and multi-layer PP and PE composite microporous film materials are used as the diaphragm of the lithium-ion supercapacitor. The electrolyte uses 1.25M lithium hexafluorophosphate as the solute, the solvent is ethylene carbonate, propylene carbonate, methyl ethyl carbonate, dimethyl carbonate, and the film-forming additives are vinylene carbonate and 1,3 propane sultone. Control the surface density of the positive and negative electrodes, set the mass ratio of the positive and negative active materials to 6.5:1, separate the positive and negative electrodes with a diaphragm and combine them into a battery cell in a laminated manner, and then weld the positive and negative electrodes of the battery to the tabs, paste Glue, the cell is reshaped by hot and cold pressing; then put it into an aluminum-plastic film casi...

Embodiment 3

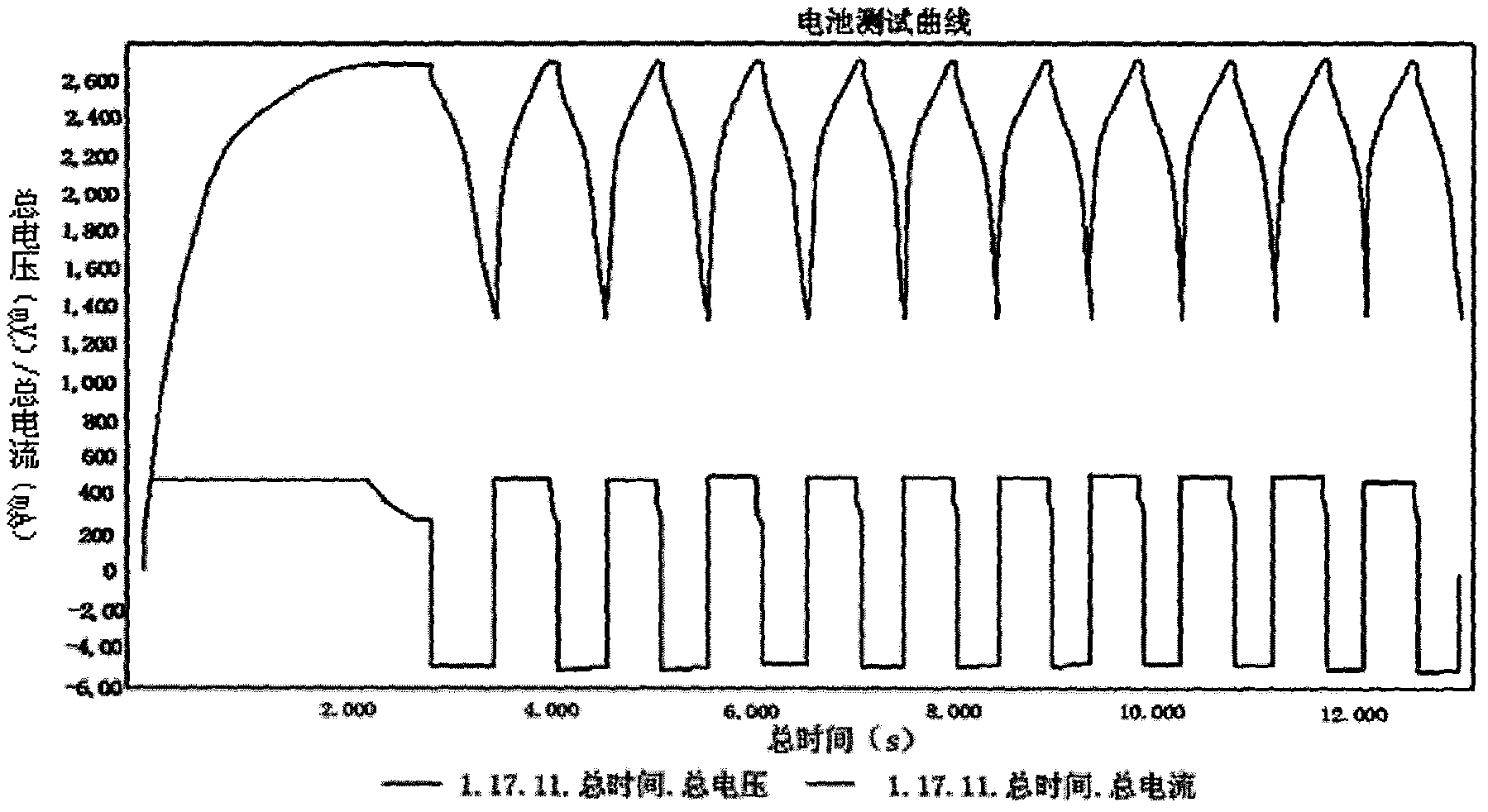

[0031] Activated carbon is used as the positive electrode active material, and mesophase carbon microspheres (MCMB) are used as the negative electrode active material. Single-layer PP, single-layer PE, and multi-layer PP and PE composite microporous film materials are used as the diaphragm of the lithium-ion supercapacitor. The electrolyte uses 1.25M lithium hexafluorophosphate as the solute, the solvent is ethylene carbonate, diethyl carbonate, dimethyl carbonate, the film-forming additives are vinylene carbonate, 1,3 propane sultone, and the positive and negative electrodes are controlled One-sided density, the mass ratio of the positive and negative active materials is 6.5:1, the positive and negative plates are separated by a diaphragm and combined into a battery cell in a laminated manner, and then the positive and negative electrodes of the battery cell are welded with tabs and glued, and the battery cell passes through Hot and cold pressure shaping; then put it into an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com