Holt-melting heat-conducting film, heat-conducting liner including hot-melting heat-conducting film and preparation method and preparation device thereof

A technology for thermally conductive gaskets and preparation devices, applied in lamination devices, chemical instruments and methods, cooling/ventilation/heating transformation, etc., can solve the problem that large-scale industrial applications cannot be realized, automatic production is difficult to achieve, and graphite sheets are fragile, etc. problems, to achieve the effect of increasing practicability and service life, improving heat conduction and heat dissipation, and increasing the area of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

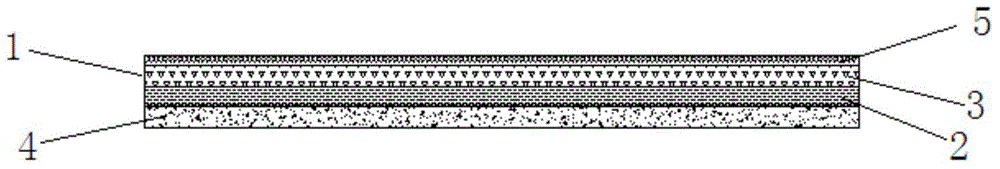

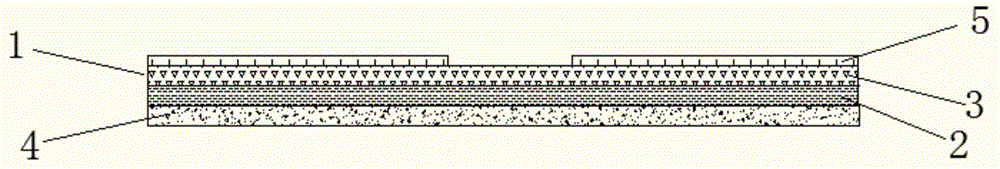

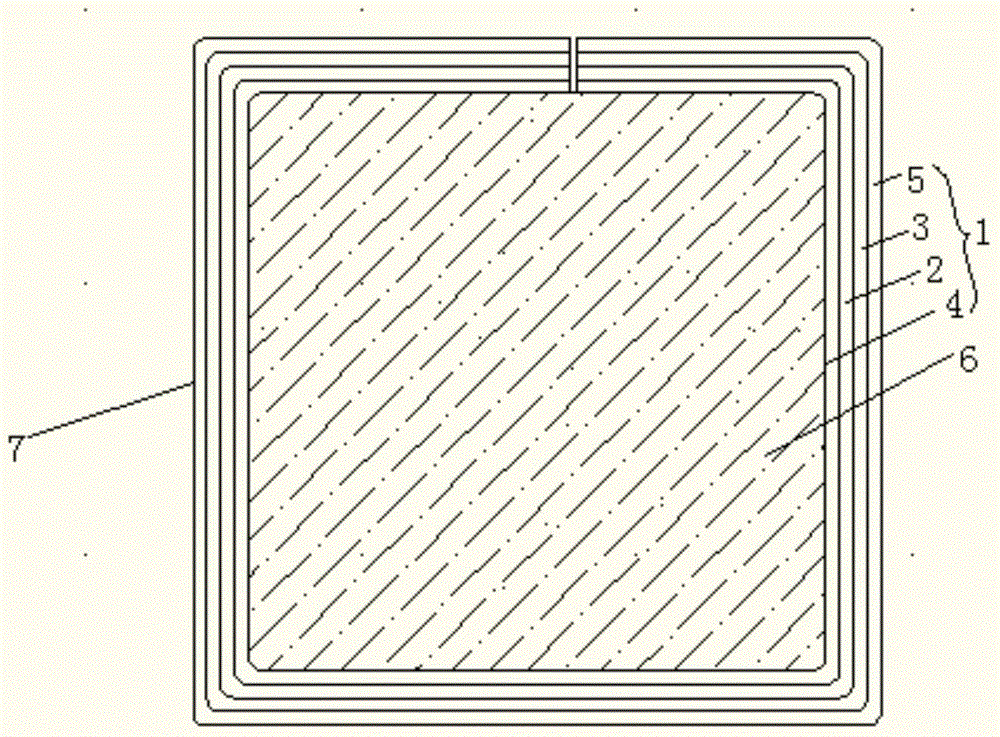

[0052] Such as figure 1 As shown, a hot-melt heat-conducting film 1 includes a heat-conducting layer 2, one side of the heat-conducting layer 2 is provided with an adhesive layer 3, and the other side of the heat-conducting layer 2 is provided with a hot-melt adhesive layer 4, and the adhesive Layer 3 is provided with a film layer 5 . The heat-conducting layer 2 is a natural graphite layer, and the film layer 5 is an insulating film layer. The insulating film layer can be a PU film, a PET film, or some films, polytetrafluoroethylene films, etc., and can also be a high-temperature-resistant film layer. Or the voltage-resistant film layer, in addition to heat conduction and heat dissipation, also has insulating properties; in addition, it can also have high-temperature or voltage-resistant properties; the hot-melt adhesive layer 4 is heated and melted, and is firmly bonded with the substrate. Adhesive layer 4 facilitates the automatic production of the heat-conducting gasket of...

Embodiment 2

[0055] Such as figure 1 As shown, a hot-melt thermally conductive film 1 includes a synthetic graphite layer 2, one side of the synthetic graphite layer 2 is provided with an adhesive layer 3, and the other side of the synthetic graphite layer 2 is provided with a hot-melt adhesive layer 4. The adhesive layer 3 is provided with a conductive film layer 5 . The conductive film layer can be a metal foil film layer, such as a copper foil film layer, an aluminum foil film layer, a silver foil film layer, a gold foil film layer, a zinc foil film layer, an iron foil film layer or an aluminum alloy foil film layer, an adhesive layer 3 and a thermal The melt adhesive layer 4 can not only prevent the graphite layer from falling off, but also prevent the hot-melt heat-conducting film 1 from breaking, increasing the practicability and service life of the hot-melt heat-conducting film 1 .

[0056] The above-mentioned hot-melt heat-conducting film 1, in addition to fast heat conduction and...

Embodiment 3

[0058] Such as figure 1 Shown, a kind of hot-melt heat-conducting film 1 comprises graphene layer 2, and one side of described graphene layer 2 is provided with viscose layer 3, and the other side of described graphene layer 2 is provided with hot-melt adhesive layer 4, so The adhesive layer 3 is provided with an antistatic film layer or an anti-EMI film layer 5 . In addition to fast heat conduction and heat dissipation, it also has antistatic or anti-electromagnetic wave performance; the hot-melt adhesive layer 4 is heated and melted, and is firmly bonded to the substrate. The adhesive layer 3 and the hot-melt adhesive layer 4 can prevent the graphene layer 2 from falling off. It can also prevent the hot-melt heat-conducting film 1 from breaking, and increase the practicability and service life of the hot-melt heat-conducting film 1 . In addition, the use of the hot-melt adhesive layer 4 facilitates the automatic production of the heat-conducting gasket of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com