Device for producing ammonium sulfate by using waste sulphur generated during gas desulfuration

A technology of coal gas and ammonium sulfate, applied in the field of coking and chemical industry, can solve the problem of unusable waste sulfur and achieve the effect of improving color and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

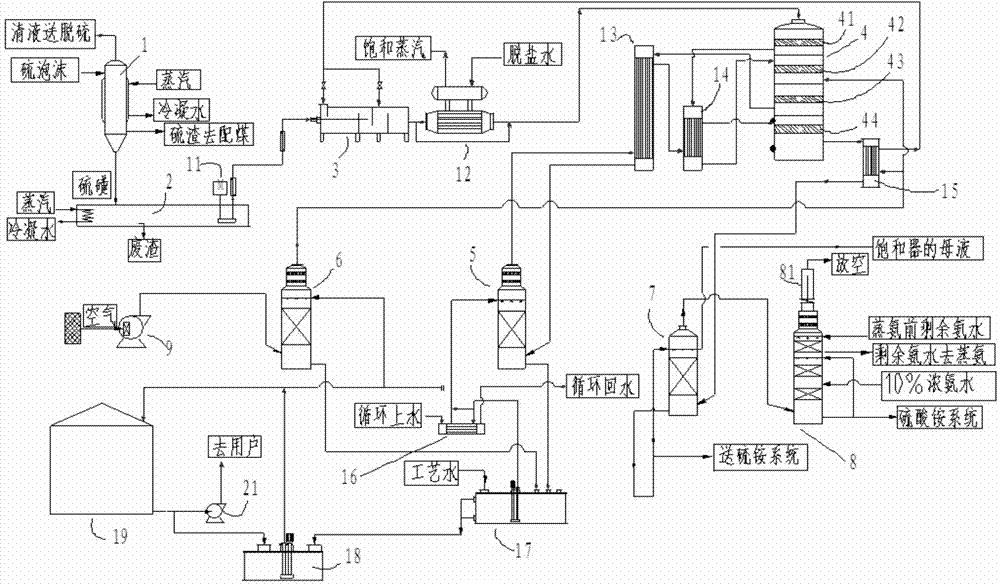

[0020] Such as figure 1 As shown, the sulfur content is 15.5%, the water content is 80.9%, and other impurities are 3.6% (including coke powder, coal powder, tar, ammonium thiocyanate, ammonium thiosulfate, ammonium sulfate, and catalyst residues), using a continuous molten sulfur purifier After purification, the sulfur was obtained with a purity of 99.6%.

[0021] After the sulfur containing 99.5% sulfur is subjected to secondary oxidation (including the primary absorption tower), the composition (volume %) of the obtained gas is SO 2 : 0.059%, SO 3 : 0.308%, O 2 : 12.023%, N 2 : 87.61%.

[0022] Composition of the above into SO 2 : 0.059%, SO 3 : 0.308%, O 2 : 12.023%, N 2 : 87.61% of the gas is absorbed by the circulating mother liquor of ammonium sulfate (the specific gravity of the mother liquor is 1.26g / cm 3 , the crystallization ratio is less than 10%, the acidity of the mother liquor is 3.5-4.5%, and the liquid-gas ratio (V / V) is 1:10; and then absorbed by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com