A flexible graphene conductive electrode, preparation method, application and flexible and bendable supercapacitor

A conductive electrode and flexible graphite technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, battery electrodes, hybrid capacitor electrodes, etc., can solve the problems of incomplete hardness and complicated process of conductive electrodes, and achieve the retention of conductivity and low cost , Improve the effect of energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

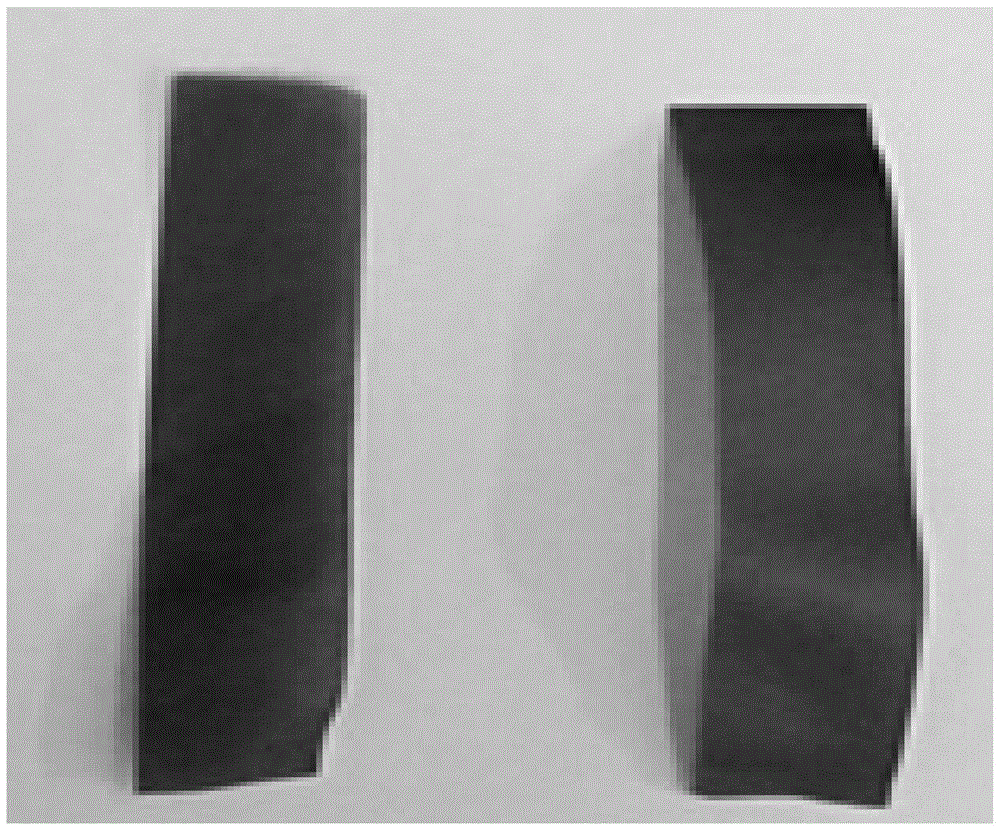

[0052] The flexible graphene conductive electrode of this embodiment is a flexible electrode made of graphene flakes made of graphite material through electron intercalation-gas phase exfoliation, and then self-assembled from the graphene flakes in a solution. The monolithic size of the graphene sheet is 10nm 2 ~1000μm 2 , the number of carbon atomic layers is 1-100. In the flexible electrode, the mass percentage of graphene material is 100%.

[0053] The preparation method of the flexible graphene conductive electrode of the present embodiment comprises the following steps:

[0054] 1) Take 1 g of lithium hexafluorophosphate and add it to 1000 ml of propylene carbonate. After stirring and dispersing, add 10 g of natural flake graphite material. After stirring and ultrasonically dispersing, mixture A is obtained; the stirring speed is 120 r / min, and the time is 1 h ; The power of the ultrasound is 100W, and the time is 2h;

[0055] 2) Place the mixture A obtained in step 1...

Embodiment 2

[0062] The flexible graphene conductive electrode of this embodiment is a flexible electrode made of graphene flakes made of graphite material through electron intercalation-gas phase exfoliation, and then self-assembled from the graphene flakes in a solution. The monolithic size of the graphene sheet is 10nm 2 ~1000μm 2 , the number of carbon atomic layers is 1-100. In the flexible electrode, the mass percentage of graphene material is 100%.

[0063] The preparation method of the flexible graphene conductive electrode of the present embodiment comprises the following steps:

[0064] 1) Add 30 g of lithium hexafluorophosphate to 1000 ml of propylene carbonate, stir and disperse, then add 40 g of artificial graphite material, stir and ultrasonically disperse to obtain mixture A; the stirring speed is 60 r / min, and the time is 5 h; The power of the ultrasound is 200W, and the time is 1.5h;

[0065] 2) Place the mixture A obtained in step 1) in a closed environment, pass thro...

Embodiment 3

[0069] The flexible graphene conductive electrode of this embodiment is a flexible electrode made of graphene flakes made of graphite material through electron intercalation-gas phase exfoliation, and then self-assembled from the graphene flakes in a solution. The monolithic size of the graphene sheet is 10nm 2 ~1000μm 2 , the number of carbon atomic layers is 1-100. In the flexible electrode, the mass percentage of graphene material is 100%.

[0070] The preparation method of the flexible graphene conductive electrode of the present embodiment comprises the following steps:

[0071] 1) Add 70g of lithium hexafluorophosphate to 1000ml of carbonate (the carbonate is made by mixing 250ml of propylene carbonate and 750ml of ethylene carbonate), after stirring and dispersing, add 60g of natural flake graphite material, after stirring and ultrasonically dispersing , to obtain mixture A; the stirring speed is 100r / min, and the time is 2h; the ultrasonic power is 400W, and the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com