Method for recycling disulfide during production of low-sulfur MTBE (methyl tert-butyl ether) product

A disulfide and product recovery technology, applied in the field of oil refining and chemical industry, can solve the problems of difficult control of the liquid level at the bottom of the tower and small content of disulfide, and achieve the effects of strong practicability, simple control and operation, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

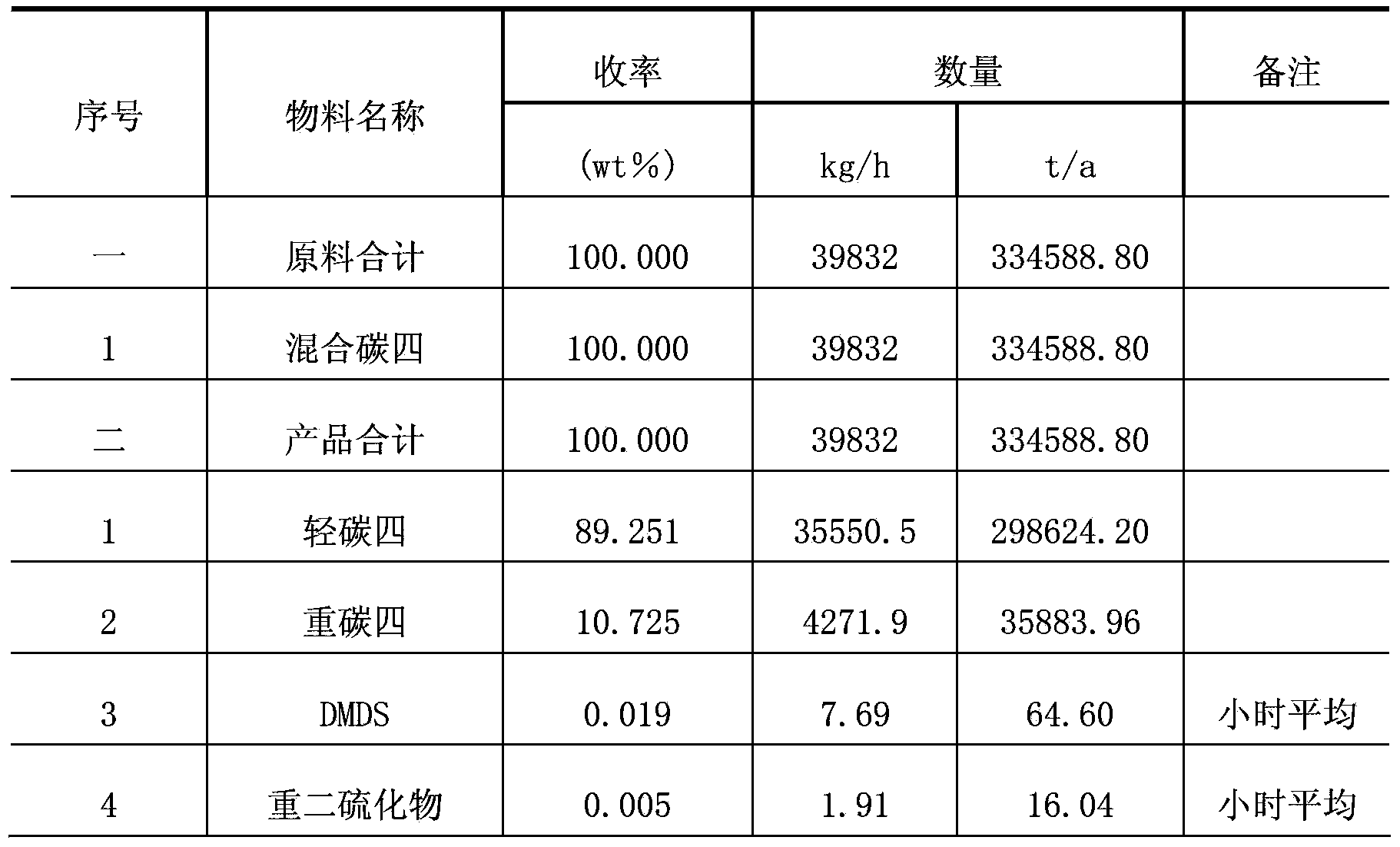

[0022] (1) C4 raw material processing capacity

[0023] The C4 raw material processing capacity is 39832kg / h (see Table 4).

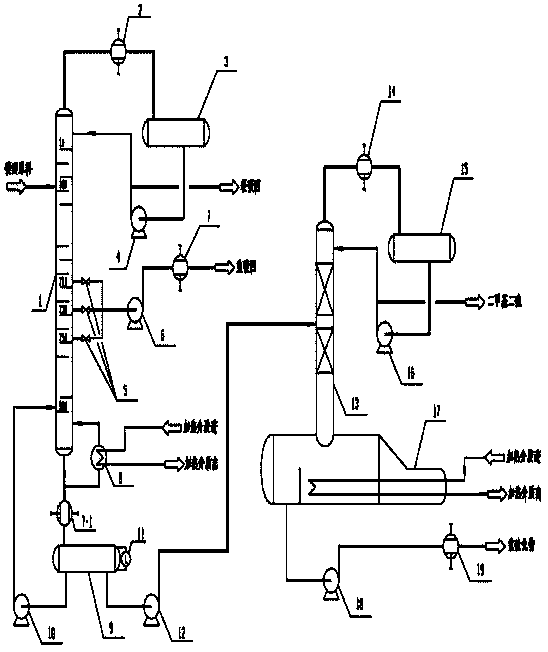

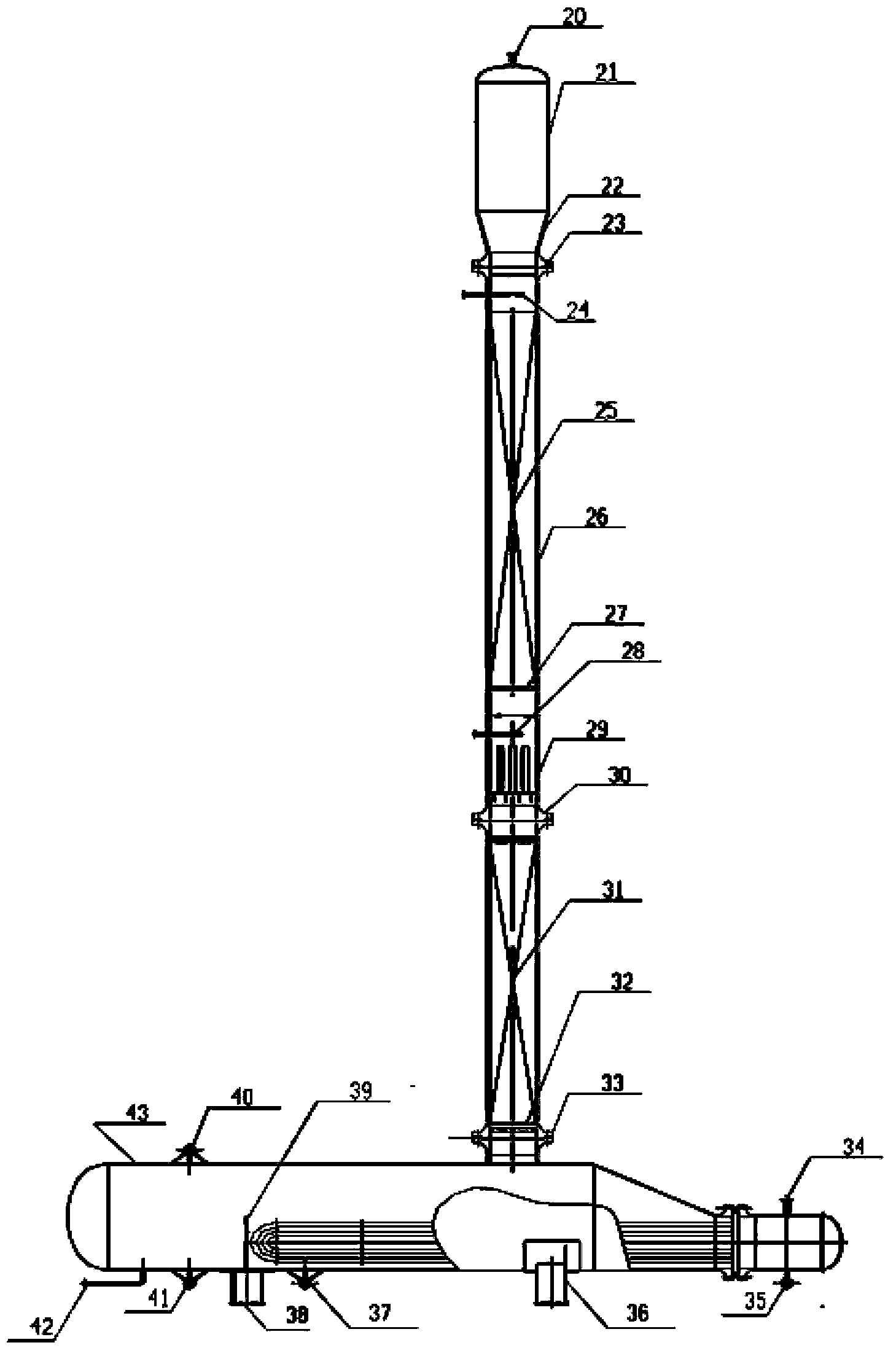

[0024] (2) Brief description of the process flow

[0025]The carbon four raw material from the gas fractionation device enters the carbon four component splitting tower, and the actual number of trays in this tower is 90. Counting from top to bottom, the position of the mixed carbon four feed plate is between the 8th and 12th trays. The light carbon four coming out from the top of the tower: After being cooled by the cooler, it enters the reflux tank, and part of the light carbon four is drawn out by the reflux pump as a liquid phase reflux, and the other part is sent to the MTBE device. Counting from top to bottom, set side draw outlets on the 70th, 72nd, and 74th trays of the carbon four-component splitting tower to extract butene, n-pentane, methyl mercaptan, ethanethiol, Heavier components such as isopropyl mercaptan and n-propylene mercaptan; an...

Embodiment 2

[0059] Embodiment 2 and comparative example

[0060] The mixed C4 flow rate from a gas fractionation device is 40000kg / h, containing 1mg / kg of methyl mercaptan, 2mg / kg of ethanethiol, 5mg / kg of isopropyl mercaptan, 1mg / kg of n-propylene mercaptan, Sulfur 149mg / kg, diethyl disulfide 32mg / kg. For example, as the raw material of MTBE plant, the sulfur content in the produced MTBE is as high as 636.9 mg / kg, which cannot meet the environmental protection requirements, so measures must be taken to reduce the sulfur content in MTBE. Embodiment 2 adopts the method described in the present invention to remove the sulfur in the C4 raw material, comparative example adopts distillation to remove the sulfur that MTBE itself exists, is about to mix sulfur-containing MTBE with desulfurized diesel oil, and the amount of added desulfurized diesel oil is 100wt% of the total weight of the sulfur-containing MTBE, the mixed mixture enters the rectification tower, and the sulfur compounds in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com