Ho/Nd-codoped sulfuretted yttrium silicate up-conversion luminescent material, preparation method of luminescent material and organic light emitting diode

A luminescent material and co-doping technology, applied in the directions of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., to achieve the effects of being beneficial to industrialized production, easy to control the preparation process, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of holmium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0028] (1) Weighing Y 2 S 3 , SiS 2 , Ho 2 S 3 and Nd 2 S 3 Powder, respectively 1.91mmol, 2mmol, 0.06mmol, 0.03mmol;

[0029] (2) Grind the powder weighed in (1) in a corundum mortar for 40 minutes to mix evenly, then burn at 980°C for 3 hours, then cool to 250°C and keep it for 2 hours, then naturally cool to room temperature Take out the bulk product and crush it to get Y 1.91 SiS 5 : 0.06Ho 3+ , 0.03Nd 3+ Up-converting phosphors.

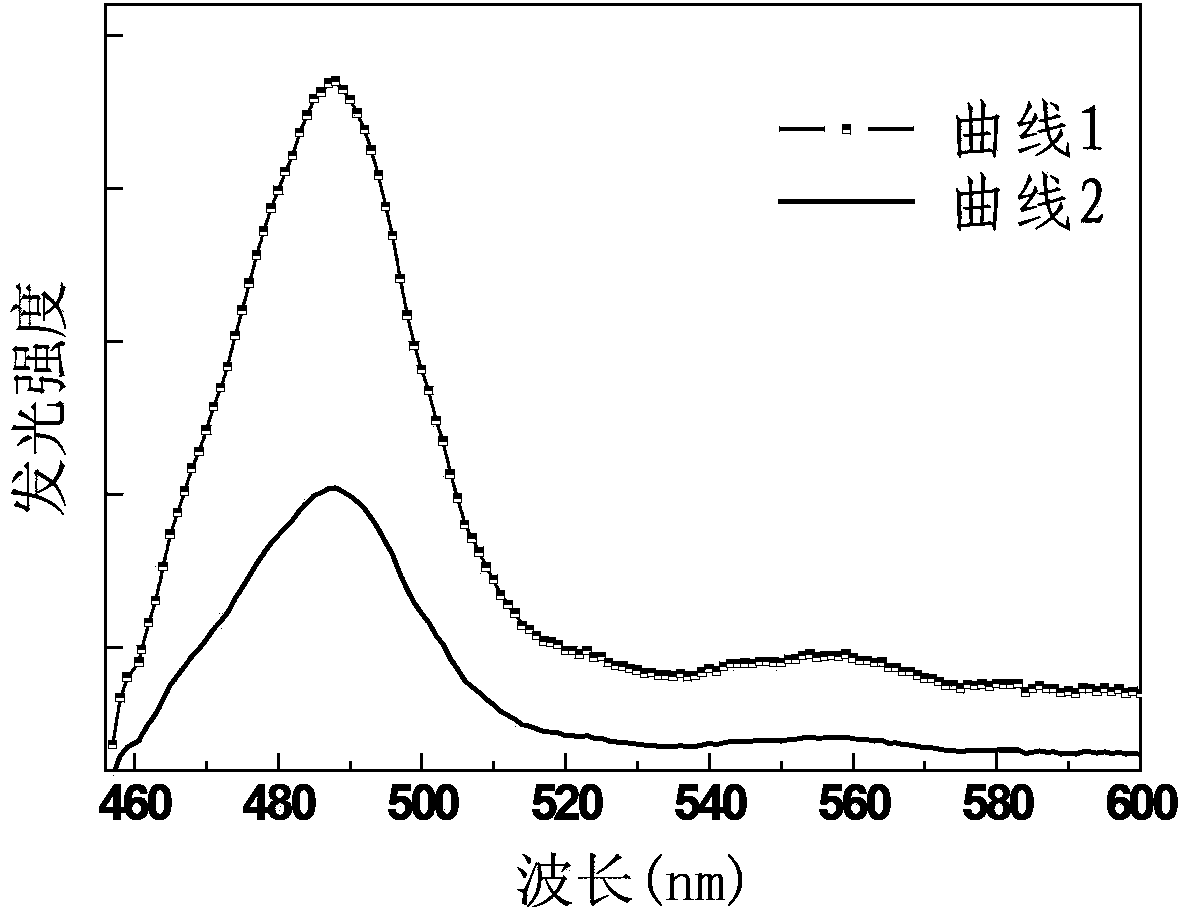

[0030] Known through spectral scanning, the obtained Y of the present embodiment 1.91 SiS 5 : 0.06Ho 3+ , 0.03Nd 3+ The optimal excitation wavelength of the up-conversion phosphor is 640nm. figure 1 Curve 1 in the figure is the photoluminescence spectrum of the holmium and neodymium co-doped yttrium thiosilicate up-conversion luminescent material in Example 1. Curve 1 shows that at an e...

Embodiment 2

[0033] A kind of preparation method of holmium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0034] (1) Weighing Y 2 S 3 , SiS 2 , Ho 2 S 3 and Nd 2 S 3 Powder, respectively 1.98mmol, 2mmol, 0.01mmol, 0.01mmol;

[0035] (2) Grind the powder weighed in (1) in a corundum mortar for 20 minutes to mix evenly, then burn at 800°C for 5 hours, then cool to 100°C and keep it for 3 hours, then naturally cool to room temperature Take out the bulk product and crush it to get Y 1.98 SiS5 : 0.01Ho 3+ , 0.01Nd 3+ Up-converting phosphors.

Embodiment 3

[0037] A kind of preparation method of holmium neodymium co-doped yttrium thiosilicate up-conversion luminescent material, the steps comprise:

[0038] (1) Weighing Y 2 S 3 , SiS 2 , Ho 2 S 3 and Nd 2 S 3 Powder, respectively 1.84mmol, 2mmol, 0.1mmol, 0.06mmol;

[0039] (2) Grind the powder weighed in (1) in a corundum mortar for 60 minutes to mix evenly, then burn at 1000°C for 0.5 hour, then cool to 500°C and keep it for 0.5 hour, then cool naturally to room temperature Take out the bulk product and crush it to get Y 1.84 SiS 5 : 0.1Ho 3+ , 0.06Nd 3+ Up-converting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com