Lithium ion battery

A lithium-ion battery and electrolyte technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effect of improving energy density and high-rate charge-discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

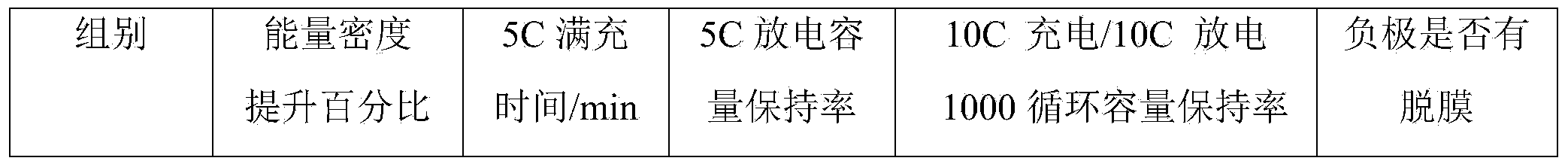

Embodiment 1

[0038] A lithium ion battery provided in this embodiment includes a positive electrode sheet, a negative electrode sheet, a separator disposed between the positive electrode sheet and the negative electrode sheet, and an electrolyte;

[0039] The negative electrode sheet includes a negative electrode current collector and a negative electrode active material layer arranged on the surface of the negative electrode current collector. In terms of mass percentage, the negative electrode active material layer includes the following components:

[0040] Negative electrode active material natural graphite 98.5%;

[0041] Negative electrode conductive agent carbon fiber 0.2%;

[0042] Negative electrode conductive agent carbon black 0.1%;

[0043] Negative electrode binder styrene-butadiene rubber 0.7%;

[0044] Negative electrode stabilizer sodium carboxymethylcellulose (CMC) 0.5%;

[0045]The viscosity of the stabilizer is 10000mPa·S;

[0046] The negative electrode current coll...

Embodiment 2

[0065] The difference from Example 1 is: the negative electrode active material is artificial graphite, and its mass content is 99.5%; the negative electrode conductive agent is carbon nanotube, and its mass content is 0.1%; the negative electrode binder is sodium alginate, and its The mass content is 0.2%; the negative electrode stabilizer is hydroxypropyl methylcellulose sodium, and its content is 0.2%, the viscosity is 7000mPa·S, and the additive includes three (pentafluoro Phenyl) borane and 2% VC in a mass ratio accounting for the total mass of the electrolyte, and a lithium salt concentration of 1.1 mol / L, the rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0071] Different from Example 1, the negative electrode active material is a mixture of natural graphite and mesocarbon microspheres, the mass ratio of the two is 5:1, and the mass content of the negative electrode active material is 98.8%; the negative electrode conductive agent is carbon nanometer tube and graphene, and the mass content of carbon nanotubes is 0.1%, and the mass content of graphene is 0.1%; the negative electrode binder is polyvinyl alcohol, and the mass content of the negative electrode binder is 0.5%; the negative electrode is stable The agent is sodium hydroxymethyl cellulose, and the mass content of the negative electrode stabilizer is 0.5%, the viscosity of the negative electrode stabilizer is 11000mPa·S, and the additive includes pentafluorophenyl borax, which accounts for 0.5% of the total mass of the electrolyte The acid ester and 2% VC in the mass ratio of the total mass of the electrolyte, the lithium salt concentration is 1.15mol / L, and the rest are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com