Production method of proteoglycan protein compound functional capsule product from edible fungi/alga

A polysaccharide protein, seaweed polysaccharide technology, applied in the functions of food ingredients, the protein composition of unicellular algae, the preparation method of peptides, etc. Overcome weak and single effects of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

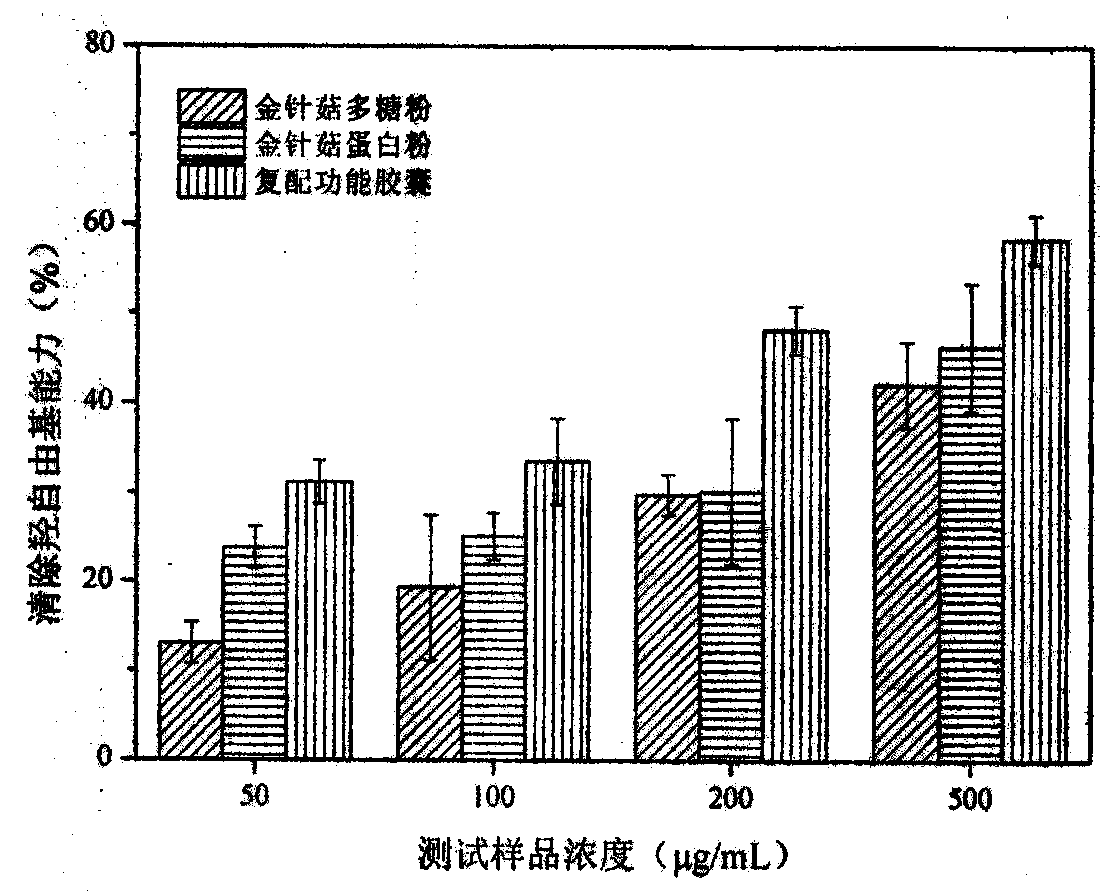

[0020] 1. Preparation of Flammulina velutipes polysaccharide and protein powder

[0021] (1) Preparation of Flammulina velutipes superfine powder: Fresh Flammulina velutipes is cleaned, cleaned, and air-dried to half-dry, then placed in an oven at 60°C for air-drying, then pulverized by a pulverizer, crushed by a double-roller crusher, and sieved with 80 mesh , pulverized by a jet mill, and sieved with 300 meshes to obtain superfine powder of Flammulina velutipes.

[0022] (2) Preparation of Flammulina velutipes polysaccharide and protein powder: Weigh Flammulina velutipes superfine powder, add 20mL 85% ethanol for every 1g of superfine powder, soak overnight at room temperature, centrifuge to get the precipitate, add 20mL of 0.05M Na 2 HPO 4 , 0.05M NaH 2 PO 4 and 0.03M NaCl in a buffer solution, stirred at room temperature for 4 hours, centrifuged and precipitated for the preparation of Flammulina velutipes polysaccharide powder, the supernatant was ultrafiltered through ...

Embodiment 2

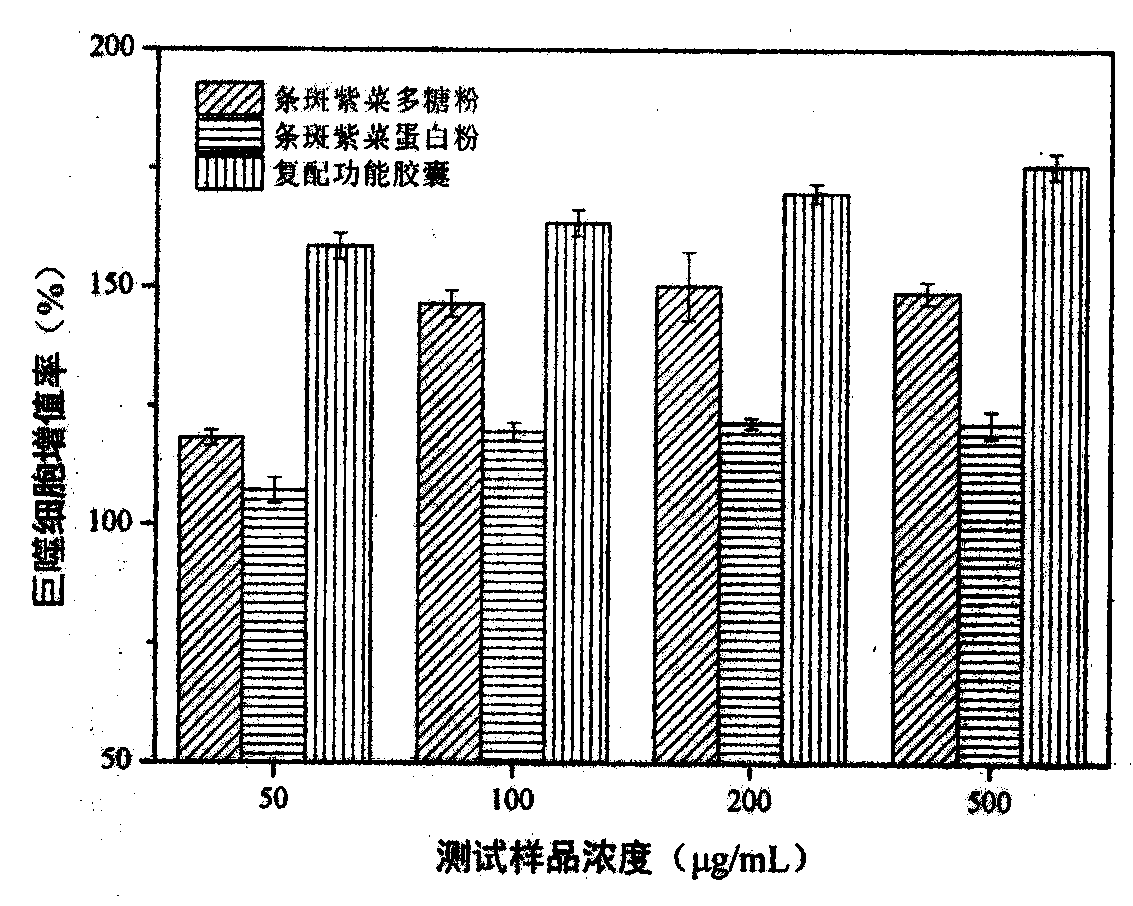

[0030] 1. Preparation of Porphyra variegata polysaccharide and protein powder

[0031] (1) Preparation of ultrafine powder of Porphyra variegata: fresh Porphyra variegata is removed from impurities, cleaned, and air-dried to semi-dry, then placed in an oven at 60°C for blast drying, then pulverized by a pulverizer, crushed by a double-roller crusher, Sieve with 80 meshes, pulverize with jet mill, and sieve with 300 meshes to obtain Porphyra zebra superfine powder.

[0032] (2) Preparation of Porphyra variegata polysaccharide and protein powder: Weigh Porphyra cerevisiae superfine powder, and use supercritical CO 2 Extraction method, degreasing pretreatment of raw materials, taking 20g of degreasing powder and adding 800mL of deionized water to swell and melt, adding papain accounting for 0.4% of the mass of degreasing powder for leaching at 70°C for 3h, then boiling water bath for 15min to inactivate the enzyme, 4000r / min After centrifugation for 20 min, the supernatant was c...

Embodiment 3

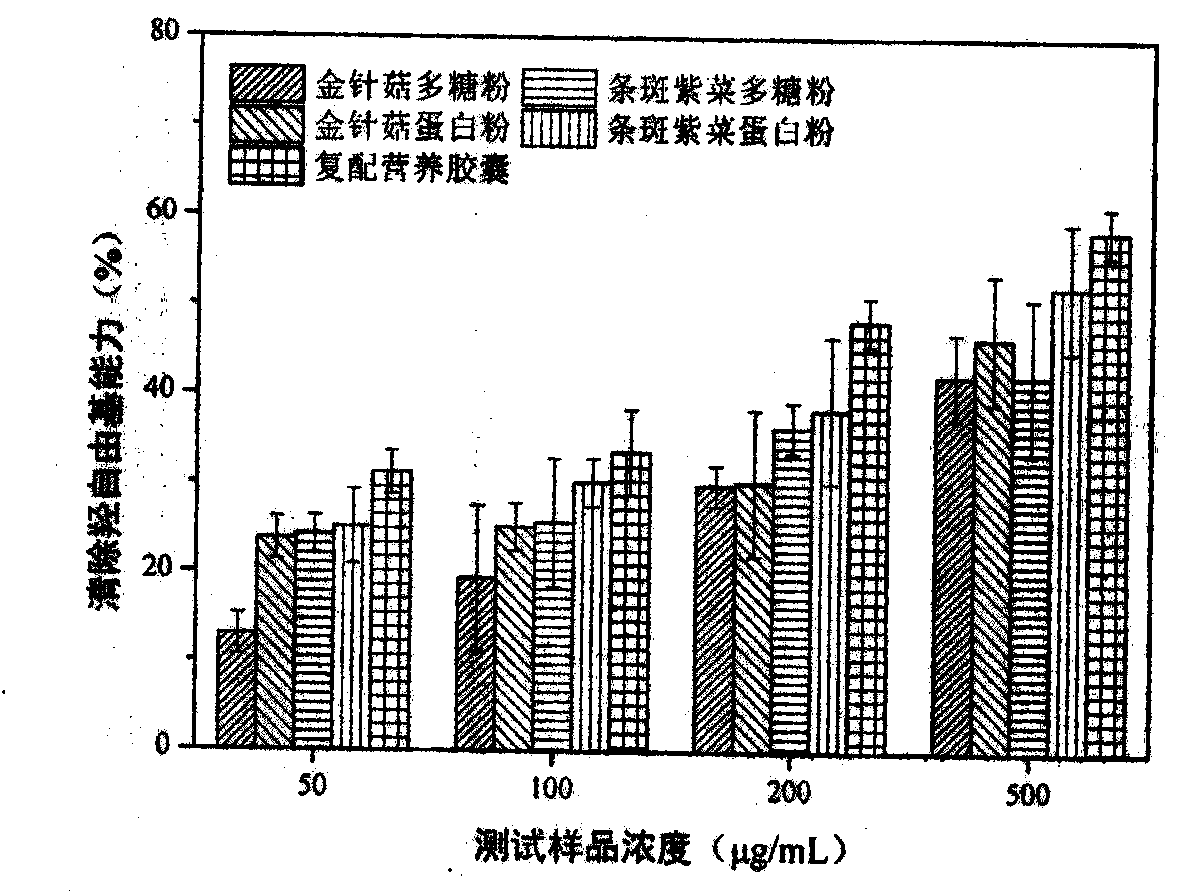

[0037] 1. Preparation of polysaccharide and protein powder of Flammulina velutipes and Porphyra variegata

[0038] (1) Preparation of superfine powder of Flammulina velutipes and Porphyra variegata: Fresh Flammulina velutipes or Porphyra variegata are cleaned, cleaned, and air-dried to semi-dry, then placed in an oven at 60°C for air-drying, and then pulverized by a pulverizer, double-rolled Crushing machine crushing, 80 mesh sieving, jet mill crushing, 300 mesh sieving, obtained Flammulina velutipes superfine powder and striped laver superfine powder.

[0039] (2) Preparation of Flammulina velutipes polysaccharides and protein powder: Weigh Flammulina velutipes superfine powder, add 15mL of 85% ethanol for every 1g of superfine powder, soak overnight at room temperature, centrifuge to get the precipitate, add 15mL of 0.05M Na 2 HPO 4 , 0.05M NaH 2 PO 4 and 0.03M NaCl buffer solution, stirred at room temperature for 3 hours, centrifuged and precipitated for the preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com