Aryl alkyl polyol ester and preparation method and application thereof

A technology for methyl aryl alkyl carboxylate and polyol ester is applied in the field of aryl alkyl polyol ester and preparation thereof, and can solve the problems of high product cost, complicated synthesis process of branched chain carboxylic acid, application limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

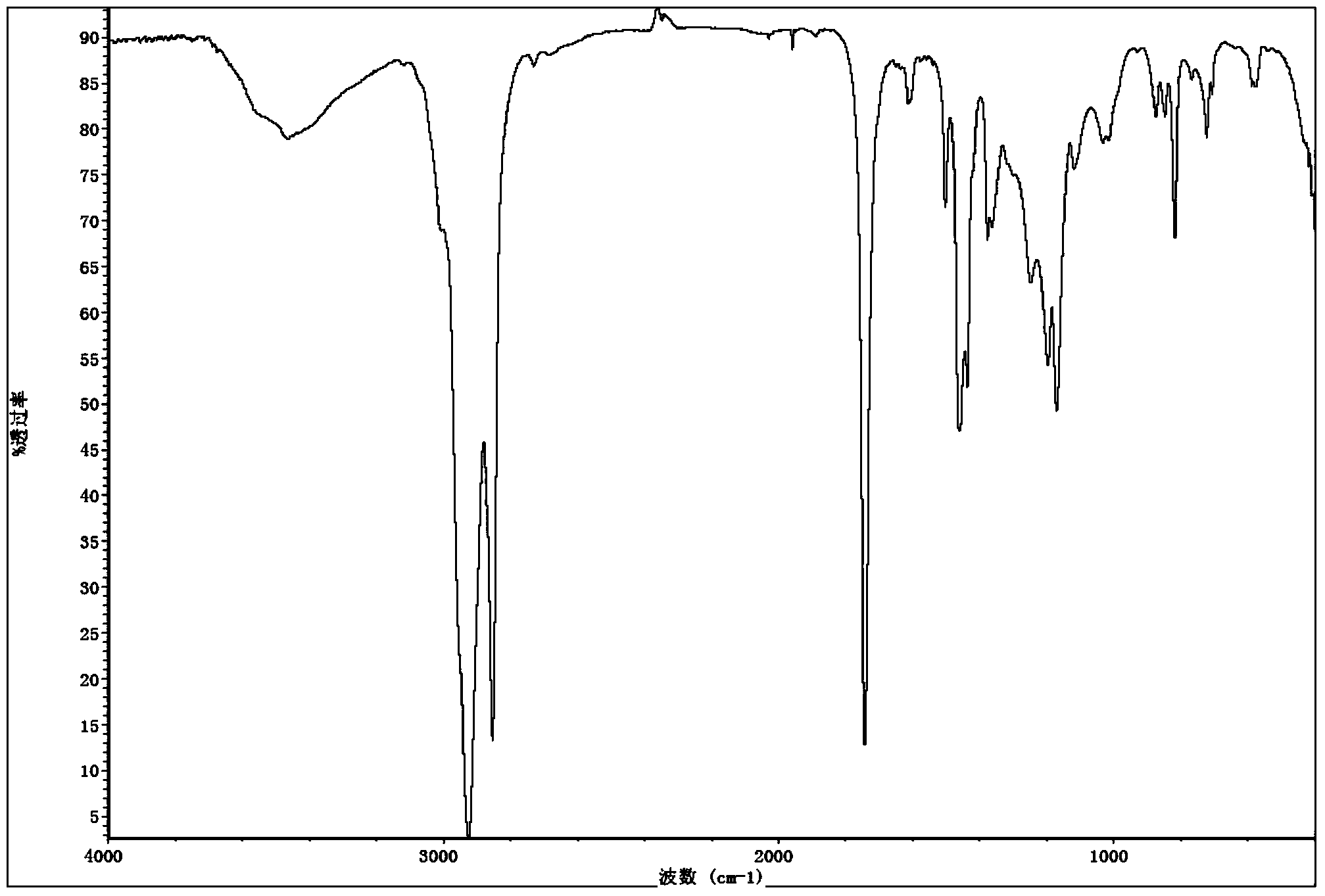

Embodiment 1

[0064] 1. Friedel-Crafts Alkylation:

[0065] ① Reactive formula

[0066]

[0067] Where: m+n=15.

[0068] ②Raw material specifications

[0069] Industrial-grade high-purity oleic acid C18:1 content ≥ 75.0%, iodine value (gI 2 / 100g) 80-100, water content ≤ 0.5%, peroxide value ≤ 10 (mg / Kg).

[0070] Industrial-grade methanesulfonic acid clear and transparent content ≥ 98.0% ion content ≤ 100ppm

[0071] Industrial grade m-xylene content ≥99.0%

[0072] ③ Raw material ratio

[0073] Oleic acid: methanesulfonic acid: m-xylene = 1:1.5:3.0 (molar ratio)

[0074] ④Synthesis process

[0075] In a sealed 2000-liter enamel reaction kettle, replace the air with nitrogen, add 496.9 kg of m-xylene and 225 kg of methanesulfonic acid, fill the reaction kettle with nitrogen protection, stir, heat up to 125 ° C, and start adding industrial high-purity oleic acid at a constant speed , control the reaction temperature at 130°C, add 440.6 kg of industrial high-purity oleic acid in 5...

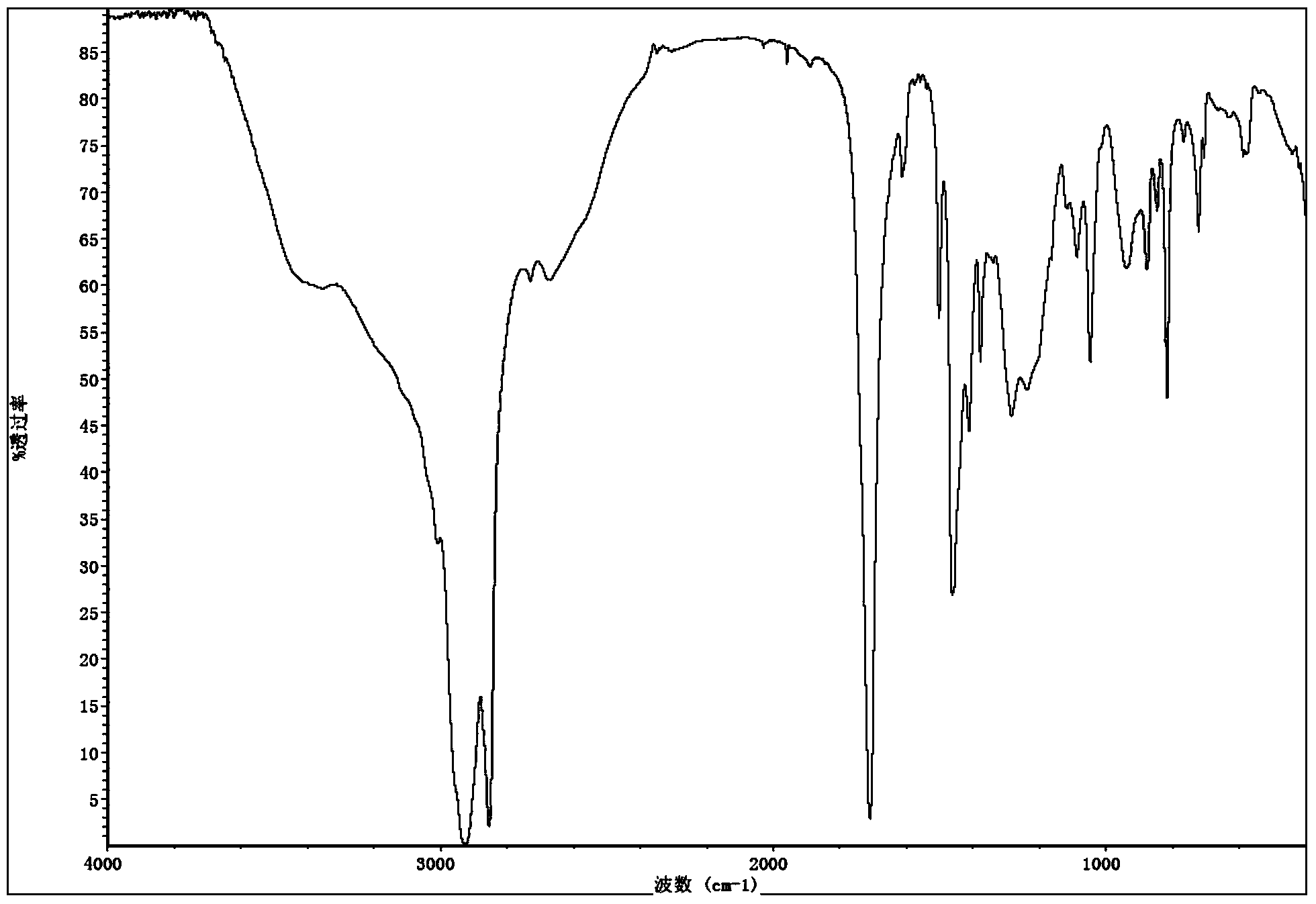

Embodiment 2

[0107] 1. Friedel-Crafts alkylation reaction: same as embodiment 1.

[0108] 2. Esterification reaction:

[0109] ① Reactive formula

[0110]

[0111]

[0112] Where: m+n=15.

[0113] ②Raw material specifications

[0114] m-xylyl octadecanecarboxylic acid: prepared by the first step, content ≥ 95%, iodine value ≤ 10 (gI 2 / 100g).

[0115] Pentaerythritol But pentaerythritol content ≥ 95% hydroxyl content ≥ 47.5% coloring degree ≤ 2.

[0116] SnO content ≥90.

[0117] ③ Raw material ratio

[0118] Pentaerythritol: m-xylyl octadecanecarboxylic acid=1:4.2 (molar ratio) 0.8% (mass ratio) of stannous oxide total material

[0119] ④ process

[0120] In a 1000ml three-neck flask, add 41g of pentaerythritol, 490g of m-xylyl octadecanecarboxylic acid, 4.3g of stannous oxide, stir at 60°C for 30min, and then react at 210°C for 5 hours under a vacuum of 0.095Mpa.

[0121] Cool down to below 80°C, and filter through G3 gravel funnel to remove stannous oxide.

[0122] Extra...

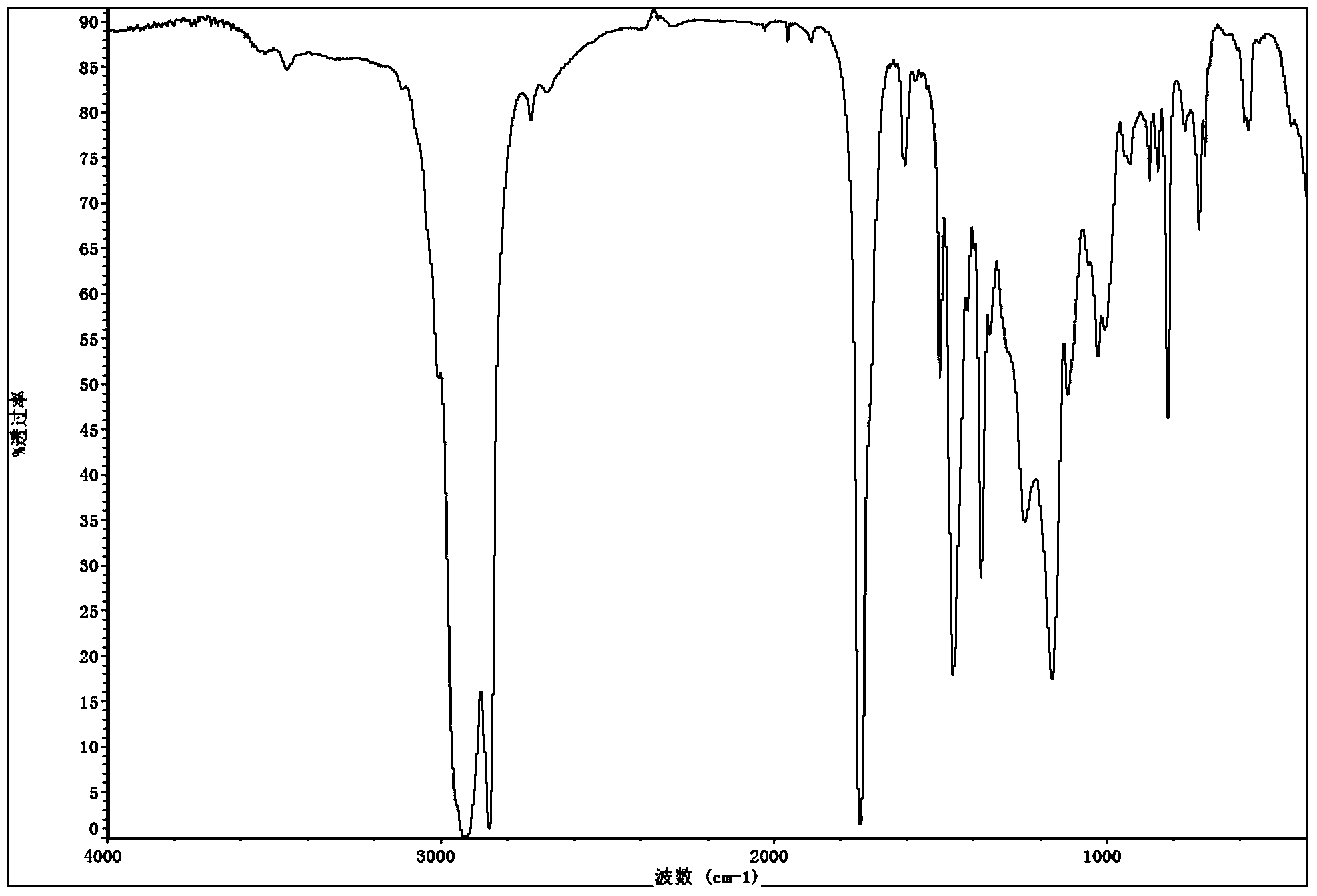

Embodiment 3

[0128] 1. Friedel-Crafts Alkylation:

[0129] ① Reactive formula

[0130]

[0131] Where: m+n=15.

[0132] ②Raw material specifications

[0133] Industrial-grade high-purity methyl oleate: C18:1 content ≥ 75.0%, iodine value (gI 2 / 100g) 80-100, water content≤0.5%, acid value≤0.5(mgKOH / g), peroxide value≤10(mg / Kg).

[0134] Industrial grade methanesulfonic acid Clear and transparent Content ≥ 98.0% Ion content ≤ 100ppm

[0135] Industrial grade m-xylene content ≥99.0%

[0136] ③ Raw material ratio

[0137] Methyl oleate: methanesulfonic acid: m-xylene = 1:1.5:3.0 (molar ratio)

[0138] ④Synthesis process

[0139] In a sealed 2000-liter enamel reaction kettle, replace the air with nitrogen, add 496.9 kg of m-xylene and 225 kg of methanesulfonic acid, fill the reaction kettle with nitrogen protection, stir, heat up to 125 ° C, and start adding industrial high-purity oleic acid at a constant speed Methyl ester, control the reaction temperature at 130°C, add 462.5 kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com