Low-temperature anti-crystalized structural adhesive and preparation method thereof

A technology of anti-crystallization and structural adhesives, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of epichlorohydrin, such as strong odor, low ambient temperature, and strong corrosion, and achieve simple and easy preparation methods Line, reduce production costs, reduce the effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The low-temperature crystallization-resistant structural adhesive provided in this example is composed of component A and component B mixed in a weight ratio of 2:1; where:

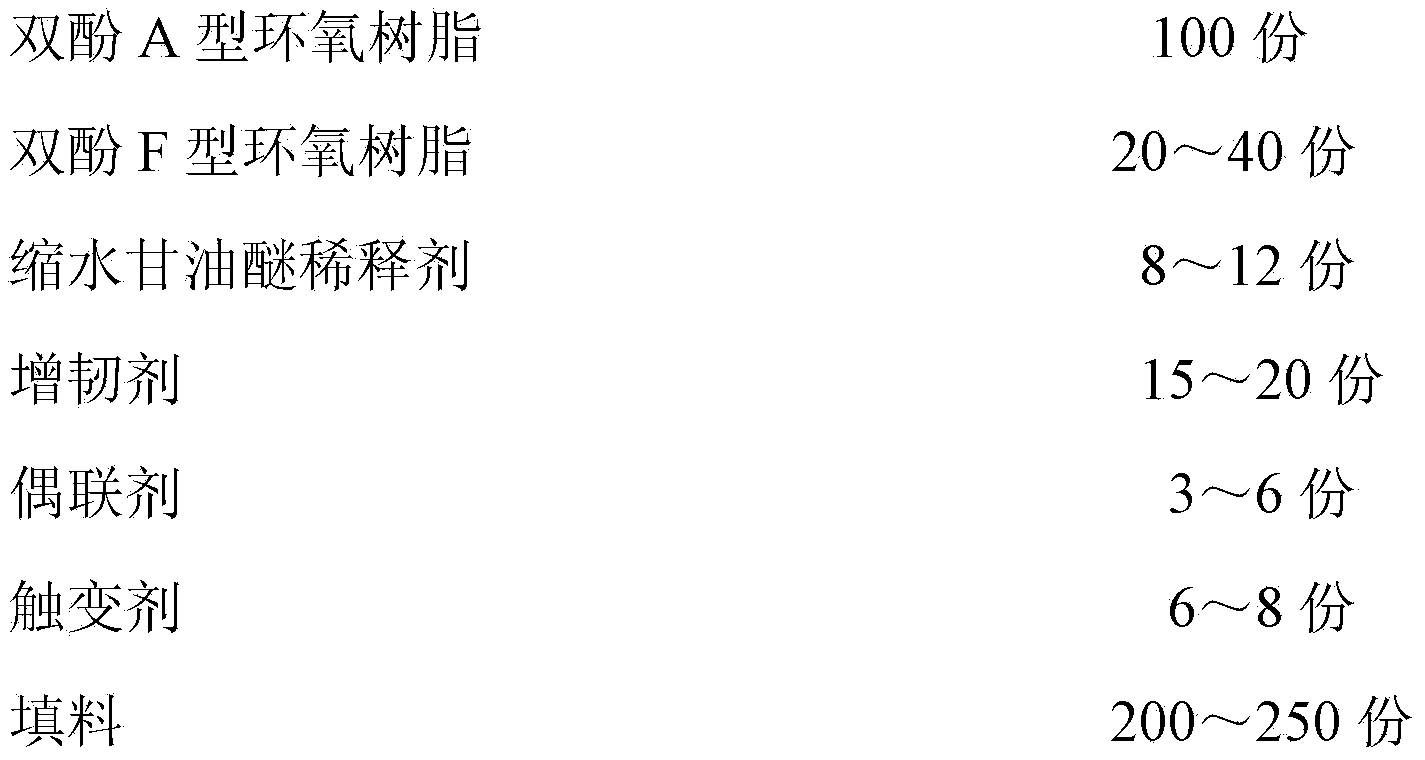

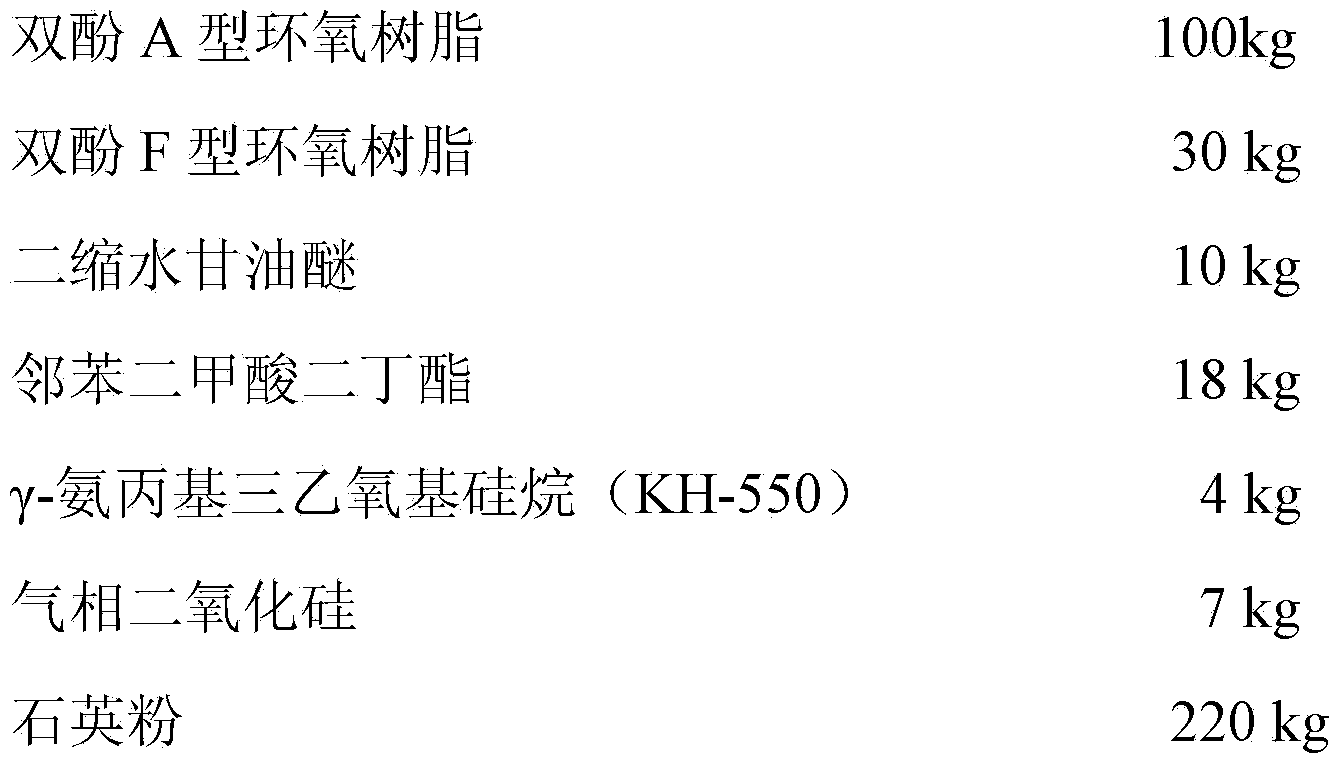

[0026] Described A component is made up of following raw material by weight:

[0027]

[0028] Described B component is made up of following raw material by weight:

[0029]

[0030] Preparation:

[0031] 1) Preparation of component A: first weigh each raw material in component A according to the above weight, and then bisphenol A epoxy resin, bisphenol F epoxy resin, diglycidyl ether, dibutyl phthalate and γ-aminopropyltriethoxysilane are added to the mixer and stirred evenly, then fumed silica is added, and finally quartz powder is added until the mixture is evenly stirred, then packaged;

[0032] 2) Preparation of component B: Weigh the raw materials in component B according to the above ratio, then add menthanediamine and 2,4,6-tris(dimethylaminomethyl)phenol into the mixer and stir eve...

Embodiment 2

[0035] The low-temperature crystallization-resistant structural adhesive provided in this example is composed of component A and component B mixed in a weight ratio of 2:1; where:

[0036] Described A component is made up of following raw material by weight:

[0037]

[0038]

[0039] Preparation:

[0040] 1) Preparation of component A: first weigh each raw material in component A according to the above weight, then bisphenol A type epoxy resin, bisphenol F type epoxy resin, polyethylene glycol diglycidyl ether, phthalate Add dioctyl formate and γ-glycidyl ether propyl triethoxysilane into the mixer and stir evenly, then add fumed silica, and finally add quartz sand until evenly stirred, then pack;

[0041] 2) Preparation of component B: Weigh the raw materials in component B according to the above ratio, then add QS-J002R and resorcinol into the mixer and stir evenly, then add bentonite, and finally add quartz sand until evenly stirred, pack ;

[0042] 3) Before use,...

Embodiment 3

[0044] The low-temperature crystallization-resistant structural adhesive provided in this example is composed of component A and component B mixed in a weight ratio of 2:1; where:

[0045] Described A component is made up of following raw material by weight:

[0046]

[0047]

[0048] Described B component is made up of following raw material by weight:

[0049]

[0050] Preparation:

[0051] 1) Preparation of component A: first weigh each raw material in component A according to the above weight, and then mix bisphenol A epoxy resin, bisphenol F epoxy resin, polypropylene glycol diglycidyl ether, polysulfide rubber and γ - Add propyltrimethylsilane to the mixer and stir evenly, then add fumed silica, and finally add silicon micropowder until it is evenly stirred, then pack;

[0052] 2) Preparation of component B: Weigh the raw materials in component B according to the above ratio, then add QS-J004R and boron trifluoride monoethylamine into the mixer and stir evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com