Extraction method of millet bran crude oil

An extraction method and grain bran technology are applied in the field of extraction of millet bran crude oil, which can solve the problems of millet bran being easily corrupted, difficult to store and transport, and the extraction rate of millet bran oil is low, and achieves good anti-oxidative stability, The effect of strong operability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for extracting millet bran crude oil, comprising the following steps:

[0027] 1) Weigh 500g of fresh millet bran and pass it through a 100-mesh sieve to remove impurities;

[0028] 2) Evenly spread the removed millet bran on the tray with a thickness of 2cm, and then use 100°C steam for 2 minutes;

[0029] 3) Evenly spray the ethanol solution of vitamin E accounting for 1% of the weight of the millet bran on the millet bran after the high-temperature steam treatment (the mass fraction of vitamin E in the ethanol solution of vitamin E is 1%);

[0030] 4) Vacuum drying at 50°C until the moisture content of millet bran is 8.13%;

[0031] 5) After cooling to room temperature, extract with n-hexane / ethanol mixed solvent (the volume ratio of n-hexane and ethanol is 1:1) at 40°C for 2 hours, wherein the solid-liquid ratio of millet bran and n-hexane / ethanol mixed solvent is 1:5, after the extraction, the solvent was removed by rotary evaporation to obtain crude mil...

Embodiment 2

[0036] A method for extracting millet bran crude oil, comprising the following steps:

[0037] Step 1)-step 4) with embodiment 1

[0038] Step 5): After cooling to room temperature, extract with n-hexane / ethanol mixed solvent (the volume ratio of n-hexane and ethanol is 3:1) at 40°C for 2 hours, wherein, millet bran and n-hexane / ethanol mixed solvent feed liquid The ratio is 1:5, and after the extraction is completed, the solvent is removed by rotary evaporation to obtain crude millet bran oil.

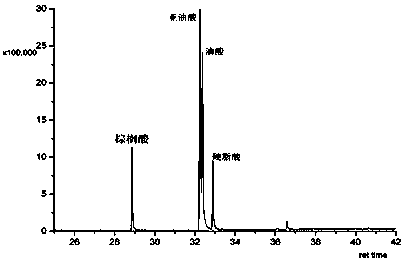

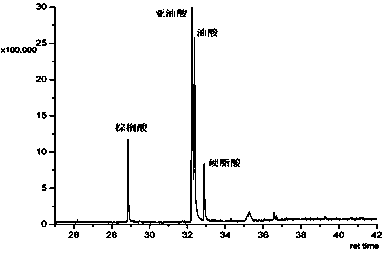

[0039] The quality of millet bran oil obtained in this example is 100.05g, and the extraction rate is 20.01%. The obtained rice bran oil is measured by the method specified in GB / T5530-2005. - Measured by the method stipulated in 2005, its peroxide value is 0.023g / 100g. GC-MS analysis showed that the content of unsaturated fatty acid in crude bran oil was about 84%. GC-MS component analysis of millet bran crude oil obtained in this example see figure 2 .

[0040] Table 2 Compone...

Embodiment 3

[0043] A method for extracting millet bran crude oil, comprising the following steps:

[0044] Steps 1), 3), 4), and 5) are the same as in Example 2;

[0045] Step 2): Spread the removed millet bran evenly on a tray with a thickness of 2 cm, and then use 100°C steam for 4 minutes at high temperature.

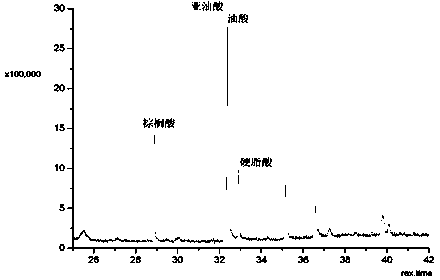

[0046] The quality of the millet bran crude oil obtained in this example is 100.21g, and the extraction rate is 20.04%. The obtained rice bran crude oil is measured by the method specified in GB / T5530-2005, and its acid value is 2.7mg KOH / g. - Measured by the method stipulated in 2005, its peroxide value is 0.038g / 100g. GC-MS analysis showed that the unsaturated fatty acid content of crude bran oil was about 85.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com