Phosphorus-containing epoxy resin, composition containing phosphorus-containing epoxy resin as essential component, and cured product

A technology of epoxy resin and composition, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc. Toxic halide and other problems, to achieve the effect of good flame retardancy, good permeability and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Although an Example and a comparative example are given and this invention is concretely demonstrated, this invention is not limited to these. Unless otherwise specified, "part" means a mass part, and "%" means a mass %. Measuring method The measurement was performed by the following methods, respectively.

[0067] The measurement method is as follows.

[0068] Epoxy equivalent: According to JIS K7236.

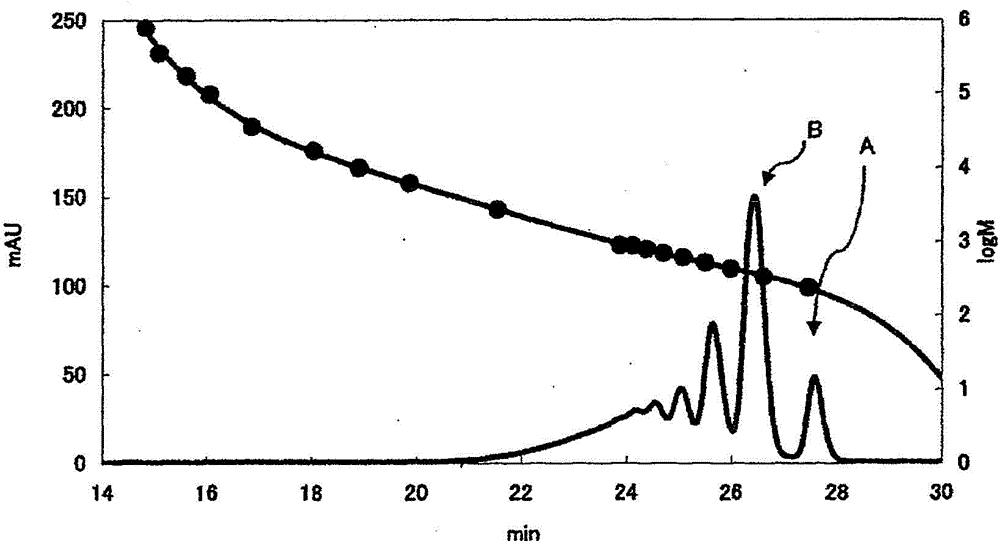

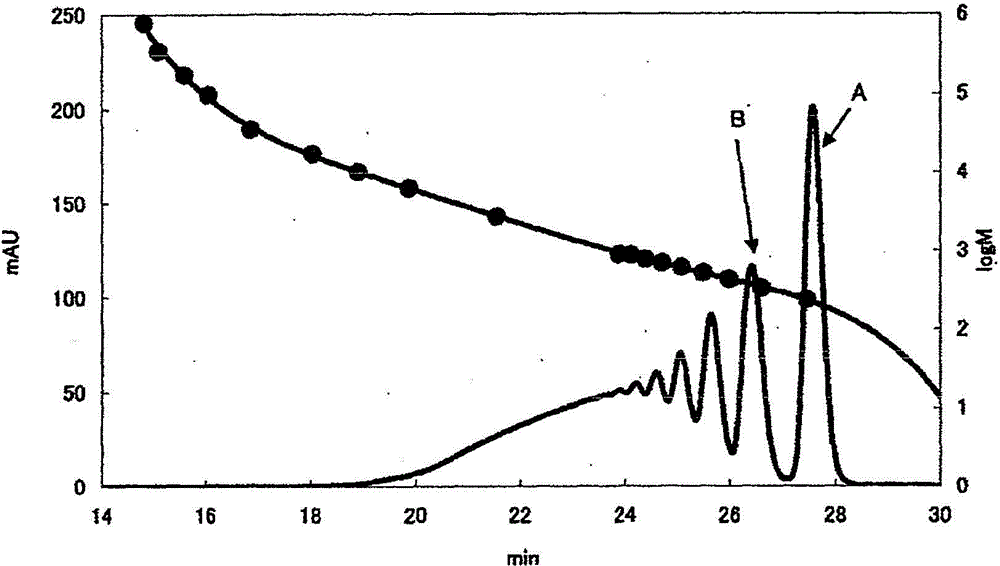

[0069] Dinuclear body content rate, trinuclear body content rate, tetranuclear body content rate, pentanuclear body content rate, number average molecular weight (Mn), weight average molecular weight (Mw), and dispersion (Mw / Mn): Gel permeation chromatography was used to measure the molecular weight distribution. The dinuclear body content rate, trinuclear body content rate, tetranuclear body content rate, and pentanuclear body content rate were calculated from the peak area %, and the number average molecular weight, weight average molecular weight, and dispersion w...

Synthetic example 1

[0078] Synthesis Example 1 (Synthesis of Novolak Resin)

[0079] 2500 parts of phenol and 7.5 parts of oxalic acid dihydrate were charged into a 4-necked glass separable flask equipped with a stirring device, a thermometer, a condenser, and a nitrogen gas introduction device, stirred while introducing nitrogen gas, and heated to raise the temperature. Dropwise addition of 474.1 parts of 37.4% formalin was started at 80°C, and it took 30 minutes to complete the dropwise addition. Furthermore, the reaction temperature was kept at 92° C., and the reaction was performed for 3 hours. The temperature was raised, and the temperature was raised to 110° C. while removing the reaction-generated water to the outside of the system. The residual phenol was recovered at 160° C. under reduced pressure to obtain a novolak resin. Further, the temperature is raised to recover a part of dinuclear bodies. The dinuclear body content and trinuclear body content of the obtained novolac resin were...

Synthetic example 2

[0080] Synthesis example 2 (synthesis of novolac type epoxy resin)

[0081]Into the same apparatus as in Synthesis Example 1, 665.8 parts of novolac resin, 2110.8 parts of epichlorohydrin, and 17 parts of water of Synthesis Example 1 were added, and the temperature was raised to 50°C while stirring. 14.2 parts of 49% sodium hydroxide aqueous solution was added, and reaction was performed for 3 hours. The temperature was raised to 64° C., the pressure was reduced to such an extent that water reflux occurred, and 457.7 parts of a 49% sodium hydroxide aqueous solution was added dropwise over 3 hours to perform a reaction. The temperature was raised to 70° C. for dehydration, and the temperature was set to 135° C. to recover residual epichlorohydrin. Return to normal pressure, add 1232 parts of MIBK, and dissolve. 1200 parts of ion-exchanged water was added, stirred and left to stand, and the by-product common salt was dissolved in water and removed. Next, 37.4 parts of 49% aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com