Compound liquorice tablet and preparation process thereof

A technology for compound licorice tablets and licorice extract powder is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. Licorice tablets have problems such as poor clinical efficacy and unstable production process, and achieve the effect of strong expectorant effect, good clinical efficacy and reduction of loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

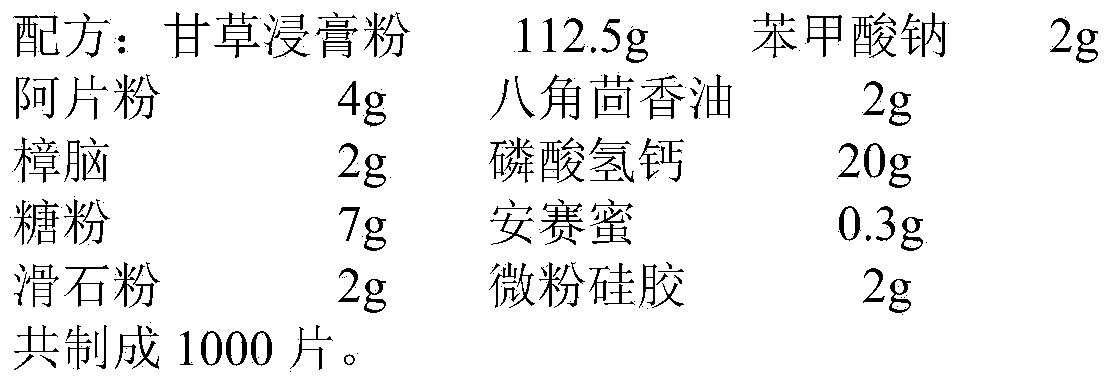

Embodiment 1

[0039]

[0040] Preparation Process:

[0041] (1) After camphor is dissolved in star anise oil, it is added in calcium hydrogen phosphate, stirred and mixed evenly, and placed for 48 hours to obtain adsorbate powder;

[0042] (2) Take licorice extract powder, opium powder, sodium benzoate, acesulfame potassium and powdered sugar by weighing the weight of raw and auxiliary materials in the prescription, grind them into fine powder respectively, cross 120 mesh sieves, and set aside;

[0043] (3) Add opium powder, sodium benzoate, sugar powder and acesulfame potassium to the licorice extract powder in equal increments, mix well to obtain a mixture, add the adsorbent powder prepared in (1), and then add talcum powder , Micropowder silica gel, mix evenly, and directly compress the powder into tablets.

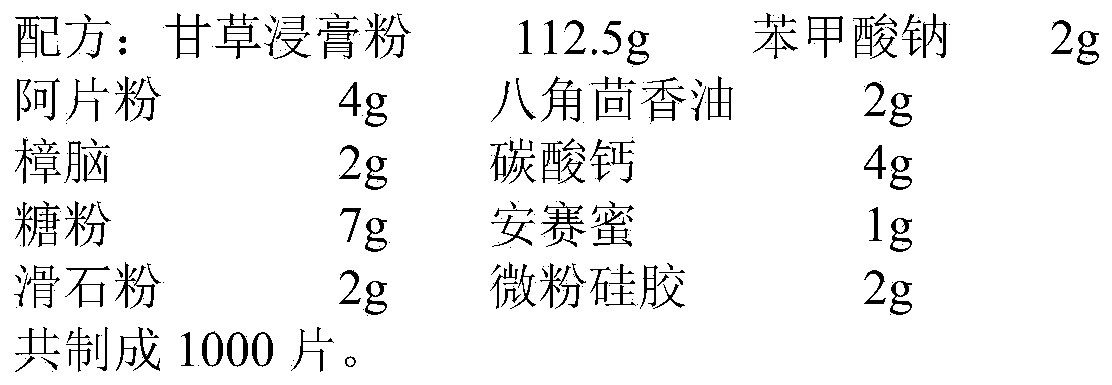

Embodiment 2

[0045]

[0046] Preparation Process:

[0047] (1) After camphor is dissolved in star anise oil, it is added in calcium carbonate, stirred and mixed evenly, and placed for 36 hours to obtain adsorbate powder;

[0048] (2) Take licorice extract powder, opium powder, sodium benzoate, acesulfame potassium and powdered sugar by weighing the weight of raw and auxiliary materials in the prescription, grind them into fine powder respectively, cross 120 mesh sieves, and set aside;

[0049](3) Add opium powder, sodium benzoate, sugar powder and acesulfame potassium to the licorice extract powder in equal increments, mix well to obtain a mixture, add the adsorbent powder prepared in (1), and then add talcum powder , Micropowder silica gel, mix evenly, and directly compress the powder into tablets.

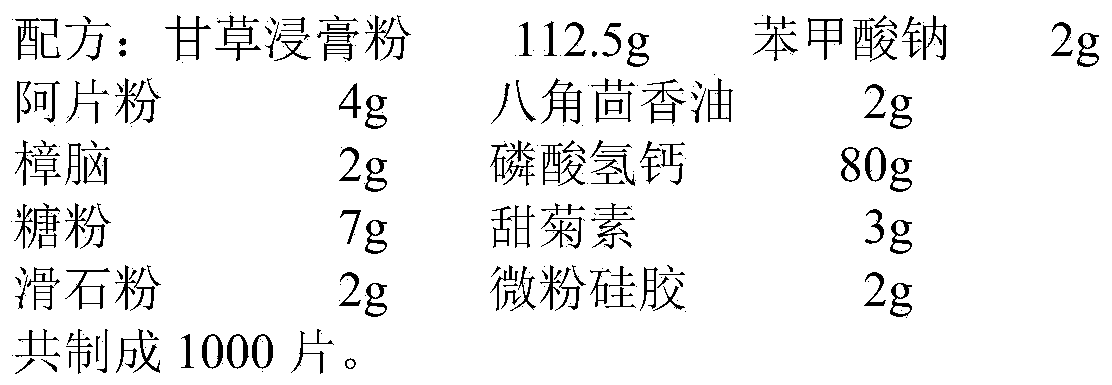

Embodiment 3

[0051]

[0052] Preparation Process:

[0053] (1) After camphor is dissolved in star anise oil, it is added in calcium hydrogen phosphate, stirred and mixed evenly, and placed for 24 hours to obtain adsorbate powder;

[0054] (2) Take licorice extract powder, opium powder, sodium benzoate, stevioside and powdered sugar by weighing the weight of raw and auxiliary materials in the prescription, grind them into fine powder respectively, pass through a 120 mesh sieve, and set aside;

[0055] (3) Add opium powder, sodium benzoate, powdered sugar and stevioside to licorice extract powder in an equal increment method, mix well to obtain a mixture, add the prepared adsorbate powder in (1), add talcum powder, micronized silica gel , mixed evenly, and the powder is directly compressed into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com