Preparation method of heavy metal ion stabilizer for dehydrating electroplating sludge

A technology for heavy metal ions and electroplating sludge, which is applied in dewatering/drying/concentrating sludge treatment, metallurgical wastewater treatment and other directions, can solve the problems of secondary treatment of lost filtrate, and achieves a simple preparation process and avoids safety and environmental risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

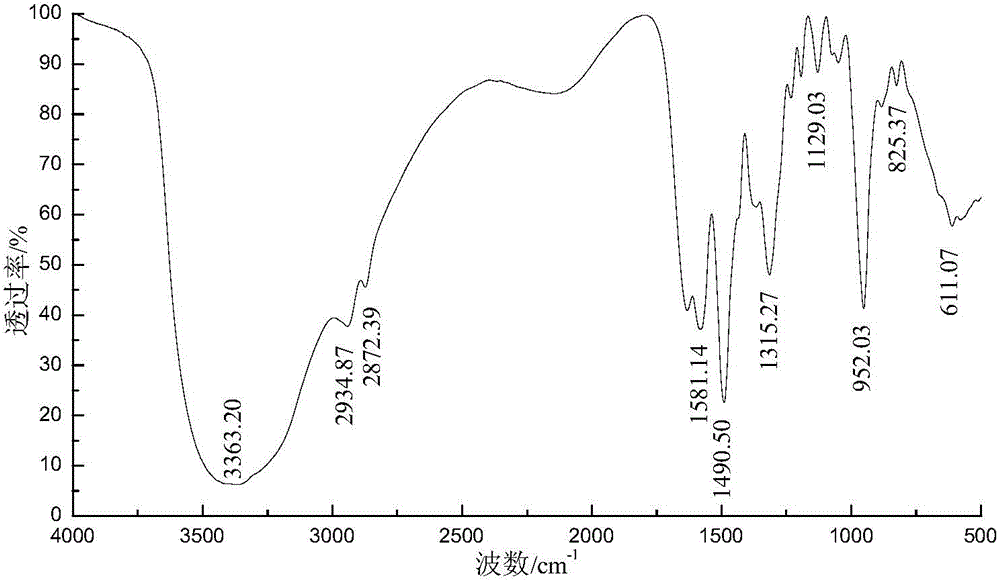

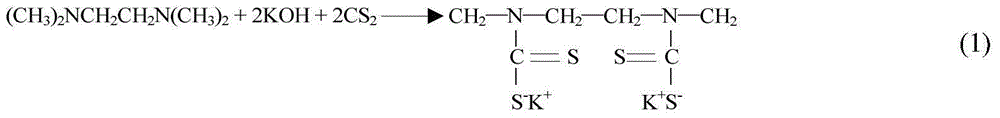

[0029] The invention provides a preparation method of a heavy metal ion stabilizer used for electroplating sludge dehydration, which is to add 59.00kg-118.00kg tetramethylethylenediamine and 112.00kg-224.00kg ultrapure water to the reaction kettle, and raise the temperature to 28°C , start the agitator to stir, the stirring speed is 300r / min; add 28.00kg-56.00kg potassium hydroxide, after the solution is colorless and transparent, slowly add 68.40kg-140.00kg carbon disulfide, add it within 0.5h, and heat up to 44°C, reflux reaction for 6 hours, the obtained yellow, viscous liquid is the dehydration stabilizer product of the present invention.

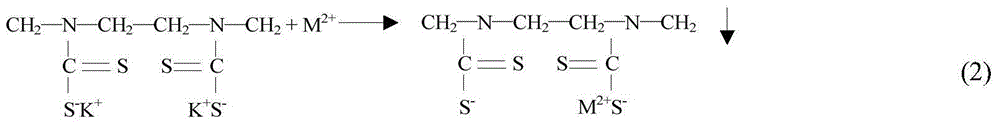

[0030] Add the prepared stabilizer solution to the undehydrated electroplating sludge by using a metering pump, mix and stir for 25-30 minutes, and perform centrifugal dehydration. When the dosage is 8-10kg / m 3 , after centrifugal dehydration (speed 2000-2500r / min), Cu 2+ 、Ni 2+ , Zn 2+ The ion stability rates were 90.80-95.77%, 91....

Embodiment 1

[0033] Add 80.50kg of tetramethylethylenediamine and 150.00kg of ultrapure water into the reaction kettle, raise the temperature to 28°C, start the agitator to stir at a stirring speed of 300r / min; add 38.33kg of potassium hydroxide until the solution is colorless After it becomes transparent, slowly add 90.50kg of carbon disulfide, complete the addition within 0.5h, raise the temperature to 44°C, and reflux for 6h. The obtained yellow, viscous liquid is the dehydration stabilizer product of the present invention.

[0034] Add the prepared stabilizer solution into the undehydrated electroplating sludge by using a metering pump, mix and stir for 30 minutes, and perform centrifugal dehydration. Take Cu 2+ 、Ni 2+ , Zn 2+As the main research object, when the dosage is 9kg / m 3 , after centrifugal dehydration at 2500r / min, Cu 2+ 、Ni 2+ , Zn 2+ The stability rates were 94.81%, 94.92%, and 71.97%, respectively.

Embodiment 2

[0036] Add 118.00kg of tetramethylethylenediamine and 224.00kg of ultrapure water into the reaction kettle, raise the temperature to 28°C, start the stirrer to stir at a stirring speed of 300r / min; add 56.00kg of potassium hydroxide, and wait until the solution is colorless After becoming transparent, slowly add 140.00kg of carbon disulfide dropwise, finish adding within 0.5h, raise the temperature to 44°C, and reflux for 6h. The obtained yellow, viscous liquid is the dehydration stabilizer product of the present invention.

[0037] Add the prepared stabilizer solution into the undehydrated electroplating sludge by using a metering pump, mix and stir for 25 minutes, and perform centrifugal dehydration. Take Cu 2+ 、Ni 2+ As the main research object, when the dosage is 8kg / m 3 , after centrifugal dehydration at 2000r / min, Cu 2+ 、Ni 2+ The stability rates were 90.80% and 91.91%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com