Method for extracting mesona chinensis benth polysaccharide through microbial fermentation

A microbial fermentation method and the technology of celestial grass polysaccharides, which are applied in the field of microbial fermentation to extract polysaccharides from plants, can solve the problems of low yield and large alcohol consumption, and achieve high yield, reduced emissions, and low-carbon and environmental protection in the extraction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

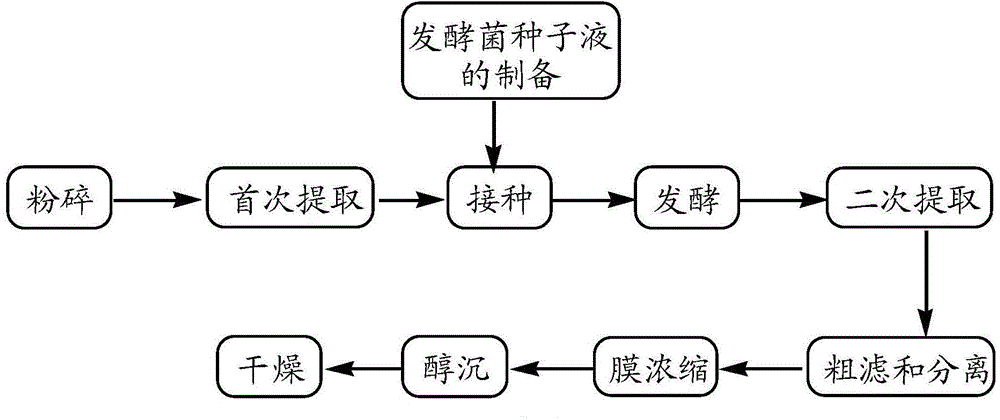

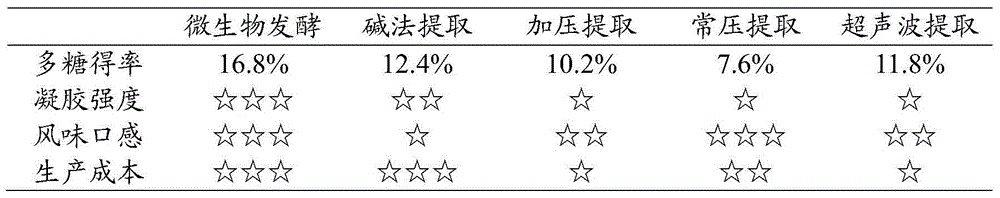

Method used

Image

Examples

Embodiment 1

[0035] 1) Pulverization: The dried grass jelly was pulverized to 20 mesh by a multifunctional pulverizer.

[0036] 2) First extraction: put the pulverized grass jelly into a fermenter, add 8 times the volume of boiling pure water of jelly jelly, adjust the pH to 4 with potassium dihydrogen phosphate buffer solution, heat the extract for 40 minutes and cool to 28°C.

[0037] 3) Preparation of fermenting bacteria seed liquid: Aspergillus niger and Aspergillus oryzae were activated at a ratio of 1:2, amplified and cultured on a shaking table at 200 rpm at 25°C for 18 hours, and amplified and cultured to obtain mixed fermented bacteria seeds liquid.

[0038] 4) Inoculation: Inoculate the fermented bacteria seed liquid prepared in step 3) into the fermenter described in step 2) under aseptic conditions with an amount of 5% of the material volume in the fermenter, and stir and mix evenly.

[0039] 5) Fermentation: Seal the fermented material in step 4) and let it stand at 28° C. fo...

Embodiment 2

[0046] 1) Grinding: Grinding the dry grass jelly raw materials to 35 meshes by a multifunctional grinder.

[0047] 2) First extraction: put the pulverized grass jelly into a fermenter, add boiling pure water 6 times the volume of jelly jelly, adjust the pH to 5 with a potassium dihydrogen phosphate buffer solution, heat the extract for 50 minutes, and then cool to 30°C.

[0048] 3) Preparation of fermenting bacteria seed liquid: Aspergillus niger and Aspergillus oryzae were activated at a ratio of 1:1, amplified and cultured on a shaker at 150 rpm at 28°C for 25 hours, and mixed fermented bacteria seeds were obtained from the amplified culture liquid.

[0049] Preparation of medium: Peel potatoes, cut into pieces, add water, heat up to 121°C in a sterilizing kettle, sterilize and boil for 30 minutes, filter with gauze, add agar to the filtrate, boil and dissolve, add glucose, make up water, pack, Sterilize and reserve.

[0050] 4) Inoculation: Inoculate the fermented bacteri...

Embodiment 3

[0058] 1) Grinding: Grinding the dry grass jelly raw material to 50 mesh by a multi-functional grinder;

[0059] 2) First extraction: put the pulverized grass jelly into a fermenter, add 8 times the volume of boiling pure water of jelly jelly, adjust the pH to 6 with a potassium dihydrogen phosphate buffer solution, keep it warm for 60 minutes and then cool to 34°C.

[0060] 3) Preparation of fermenting bacteria seed liquid: Aspergillus niger and Aspergillus oryzae were activated at a ratio of 2:1, amplified and cultivated on a shaker at 200 rpm at 28°C for 20 hours, and amplified and cultivated to obtain mixed fermented bacteria seeds liquid.

[0061] Preparation of medium: Peel potatoes, cut them into pieces, add water, heat up to 121°C in a sterilizing kettle, sterilize and boil for 30 minutes, filter with gauze, add agar to the filtrate, boil to dissolve, add glucose, make up water, pack, Sterilized, spare.

[0062] 4) Inoculation: Inoculate the fermented bacteria seed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com