Sand-blasting-free diffusion nickel plating technology of rectification monocrystalline silicon wafer

A monocrystalline silicon wafer and process technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of polluted environment, excessive dust, vibration and noise, etc., to reduce production costs, low production costs, The effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

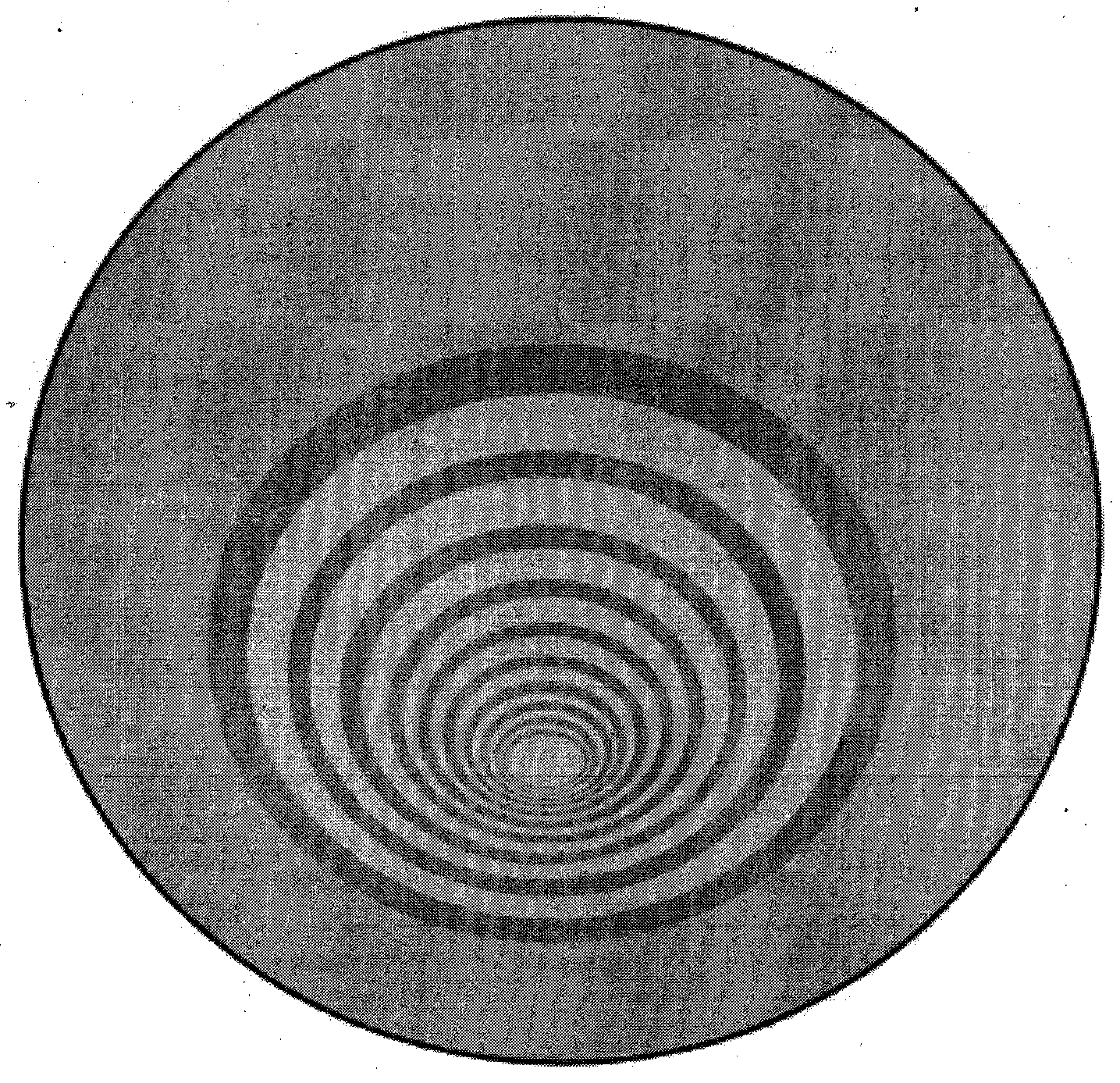

Image

Examples

Embodiment Construction

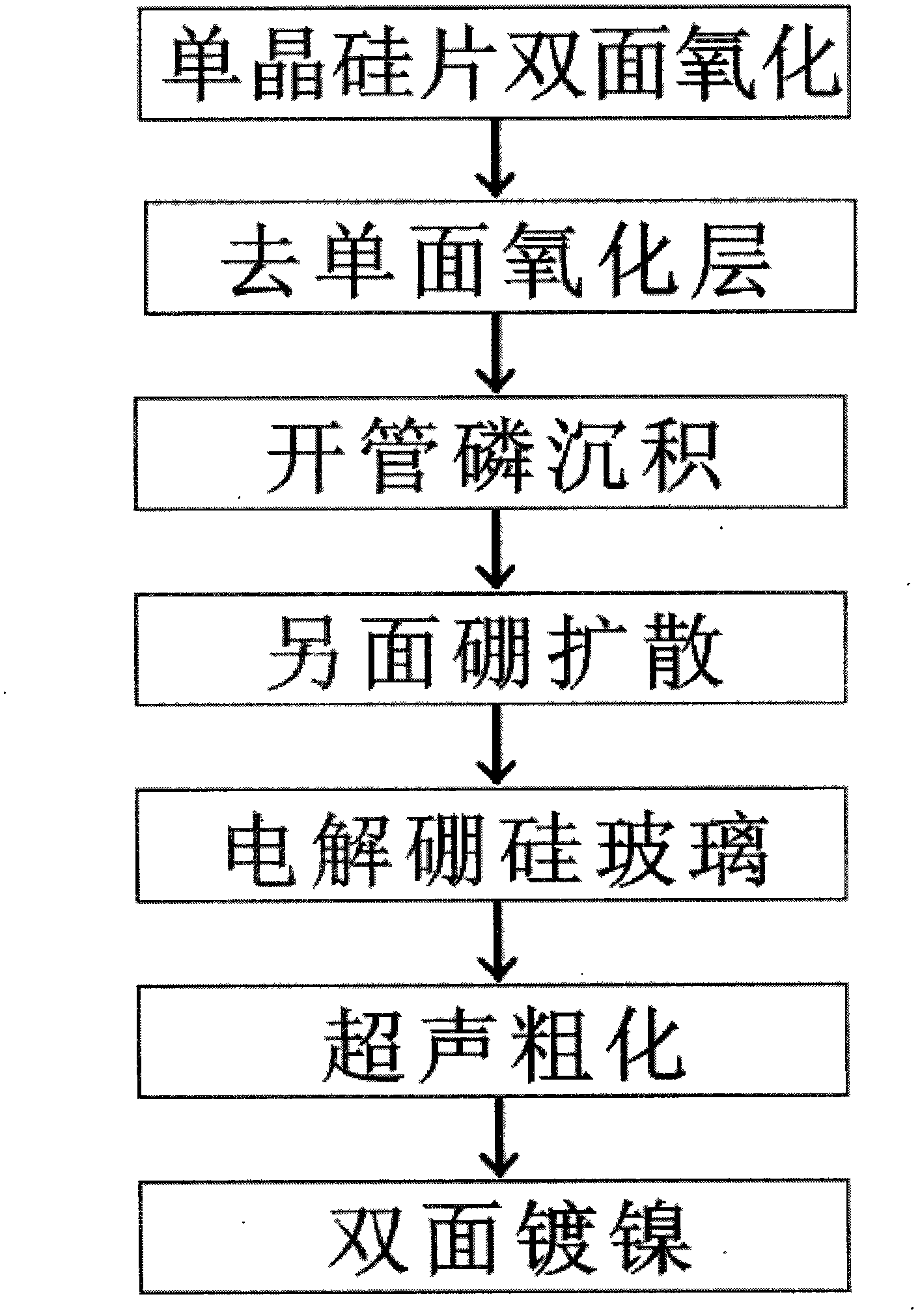

[0024] The main process flow of the rectifying single crystal silicon wafer free of sandblasting diffusion nickel plating process of the present invention is: double-sided grinding of N-type single crystal silicon wafer (raw material) - double-sided oxidation - removal of single-sided oxide layer - open-tube phosphorus deposition - Boron diffusion on the other side - Electrolytic borosilicate glass - Ultrasonic roughening - Nickel plating on both sides - Rectifying single crystal silicon wafer (product). The block diagram of its technological process is shown in the appendix of the manual. figure 2 . This manual only focuses on the implementation of new processes that have been added or transformed, and the processes that still need to be retained in traditional processes are not introduced.

[0025] The implementation of the "double-sided oxidation process": double-sided grinding of single-crystal silicon wafers, after cleaning, the double-sided oxidation process is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com