Nitrogen-doped graphene/molybdenum disulfide composite material, and preparation method and application thereof

A nitrogen-doped graphene and molybdenum disulfide technology, applied in the fields of materials science and electrochemistry, can solve the problems of limiting the activity of electrode materials, achieve the effects of enhancing cycle performance and rate performance, improving stability, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preferred embodiment of the present invention provides a method for preparing a nitrogen-doped graphene / molybdenum disulfide composite material, which specifically includes the following steps:

[0034] (1) Preparation of graphene oxide solution

[0035] Mix 1-5g of graphite flakes with 2-6g of sodium nitrate by stirring, and add 100-200mL of concentrated sulfuric acid while stirring. After stirring for half an hour, add 10-30g of potassium permanganate, then stir for one day, and place it for one week. Then add 500mL water and 20-50mL H 2 o 2 , and finally the reaction product was centrifugally dialyzed to obtain a graphene oxide solution.

[0036] (2) Preparation of nitrogen-doped graphene / molybdenum disulfide composites

[0037] Step 1. Mix graphene oxide solution, nitrogen-containing precursor, sulfur-containing and molybdenum-containing precursors in a solvent at a temperature of 40-90° C. according to a mass ratio of 1:(1-50):(5-30) , and wherein the molar r...

Embodiment 1

[0042] The present embodiment 1 provides a kind of preparation method of nitrogen-doped graphene / molybdenum disulfide composite material, specifically comprises the following steps:

[0043] (1) Preparation of graphene oxide solution

[0044] Mix 5g of graphite flakes and 5g of sodium nitrate by stirring, and slowly add 200mL of concentrated sulfuric acid while stirring, after stirring for half an hour, slowly add 20g of potassium permanganate, then stir for one day, and place it for a week, then slowly add 500mL of water, Then add 20~50mL H 2 o 2 , and finally the reaction product was centrifugally dialyzed to obtain a graphene oxide solution.

[0045] (2) Preparation of nitrogen-doped graphene / molybdenum disulfide composites

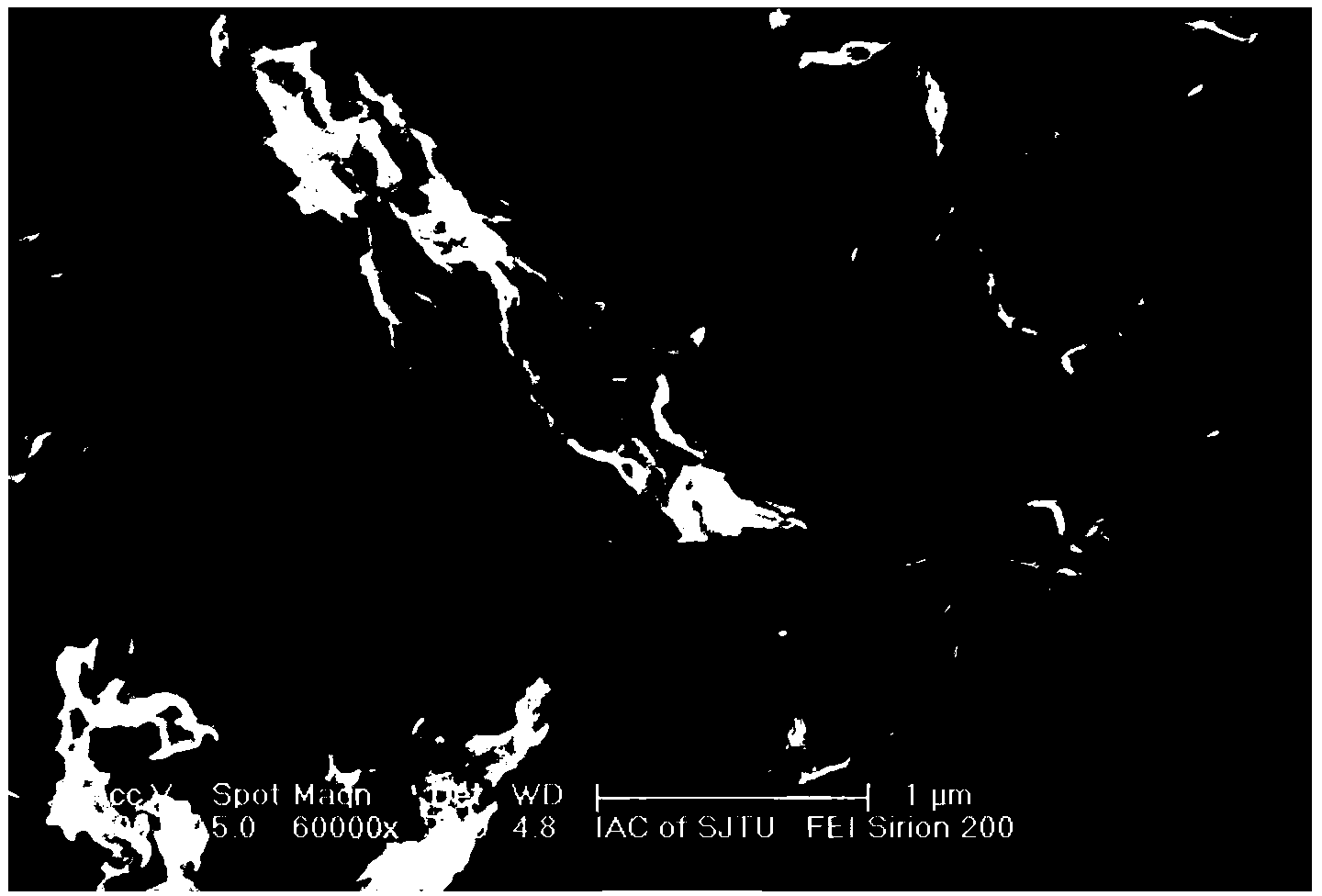

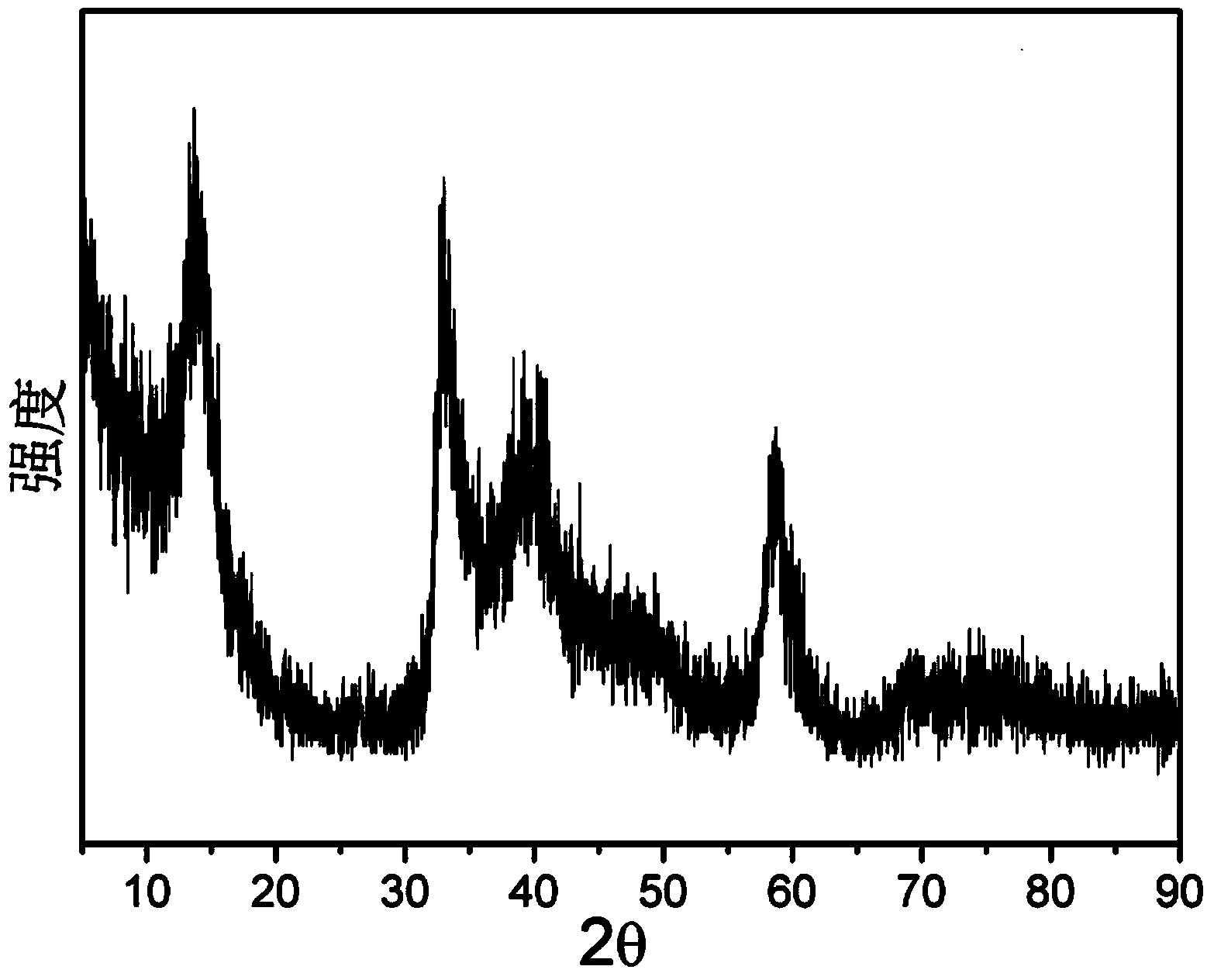

[0046] Step 1. Measure 50 mg of graphene oxide solution and disperse it in 200 mL of deionized water, then add 100 mg of graphitized carbon trinitrogen tetrachloride into it to obtain a mixed solution, ultrasonically treat the mixed solution until u...

Embodiment 2

[0050] The present embodiment 2 provides a kind of preparation method of nitrogen-doped graphene / molybdenum disulfide composite material, specifically comprises the following steps:

[0051] (1) Preparation of graphene oxide solution

[0052] Mix 5g of graphite flakes and 5g of sodium nitrate by stirring, and slowly add 200mL of concentrated sulfuric acid while stirring, after stirring for half an hour, slowly add 20g of potassium permanganate, then stir for one day, and place it for a week, then slowly add 500mL of water, Then add 50mL H 2 o 2 , and finally the reaction product was centrifugally dialyzed to obtain a graphene oxide solution.

[0053] (2) Preparation of nitrogen-doped graphene / molybdenum disulfide composites

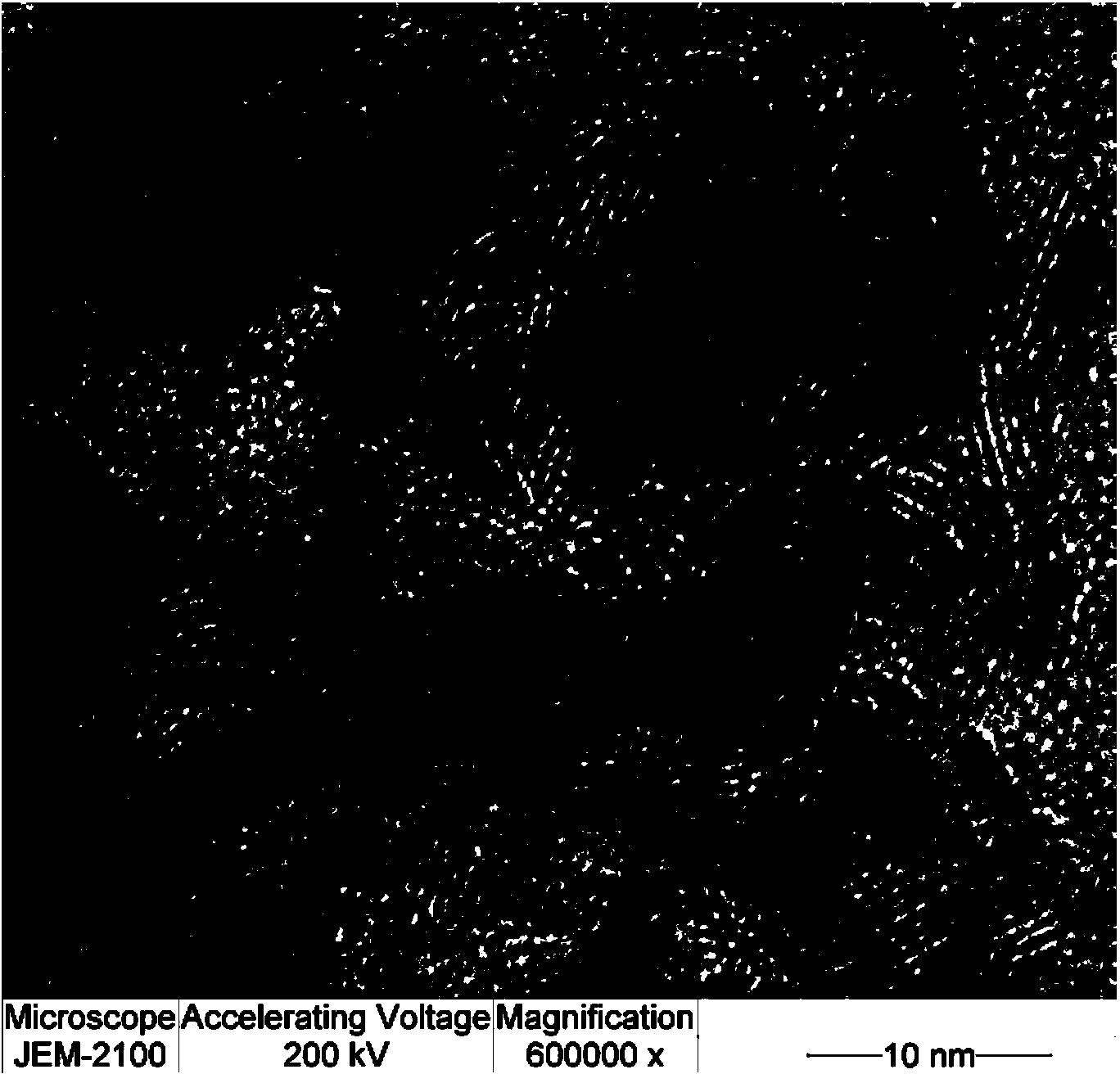

[0054] Step 1. Measure 50mg of graphene oxide solution and disperse it in 200mL of deionized water, then add 2g of urea to it to obtain a mixed solution, stir and heat the mixed solution in an oil bath at 90°C, and then put it in the mixed solution 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com