Positive pole lithium iron phosphate/carbon composite material for low-temperature battery and preparation method of composite material

A carbon composite material, lithium iron phosphate technology, applied in battery electrodes, phosphorus compounds, chemical instruments and methods, etc., can solve the problem of poor low-temperature discharge performance of lithium iron phosphate nanocrystals, high reaction equipment requirements, and increased cost pressures, etc. problems, to achieve the effect of shortening the high temperature calcination time, simplifying the synthesis process, reducing energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the positive electrode material lithium iron phosphate / carbon composite material for low-temperature batteries in this embodiment is characterized in that it includes the following steps:

[0026] a. Divalent iron compound, lithium compound, phosphorus compound and carbon source are respectively dispersed in deionized water to form a solution or suspension with a concentration of 0.5-1.5mol / L; the divalent iron compound in molar ratio: lithium compound : phosphorus compound=0.98~1:1:1~1.02; the carbon source is 1%~10% of the quality of the lithium iron phosphate cathode material obtained from the basic raw material;

[0027] b. Add the solution or suspension obtained in step a to a certain volume of liquid-phase reducing agent to form a mixed solution and then reflux at a certain temperature for 4-16 hours at normal pressure, and then separate the solid and liquid to obtain the lithium iron phosphate precursor powder ;

[0028] c. Place the li...

Embodiment 1

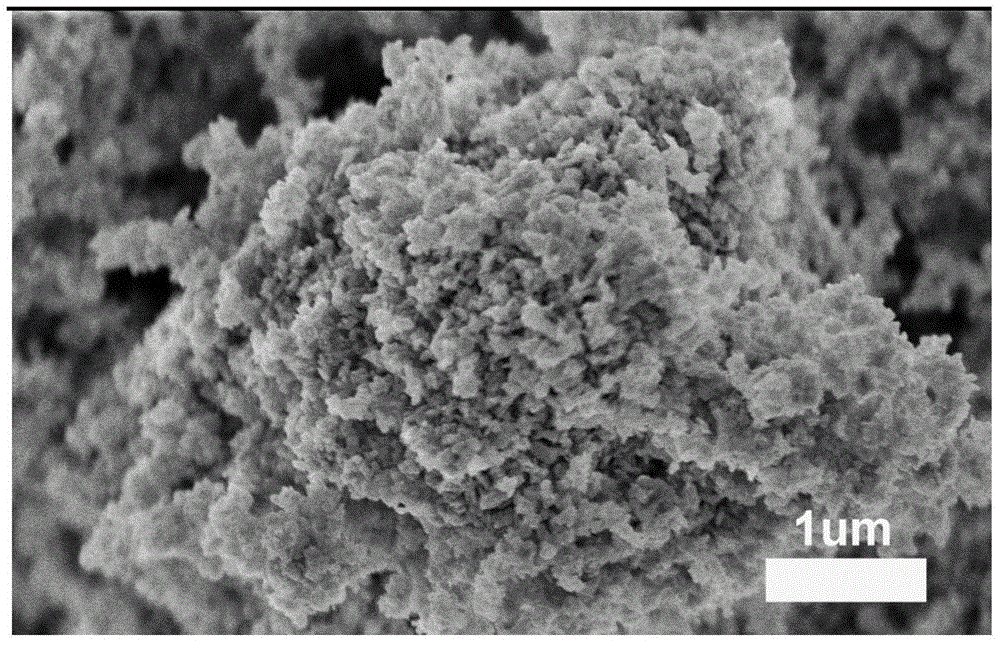

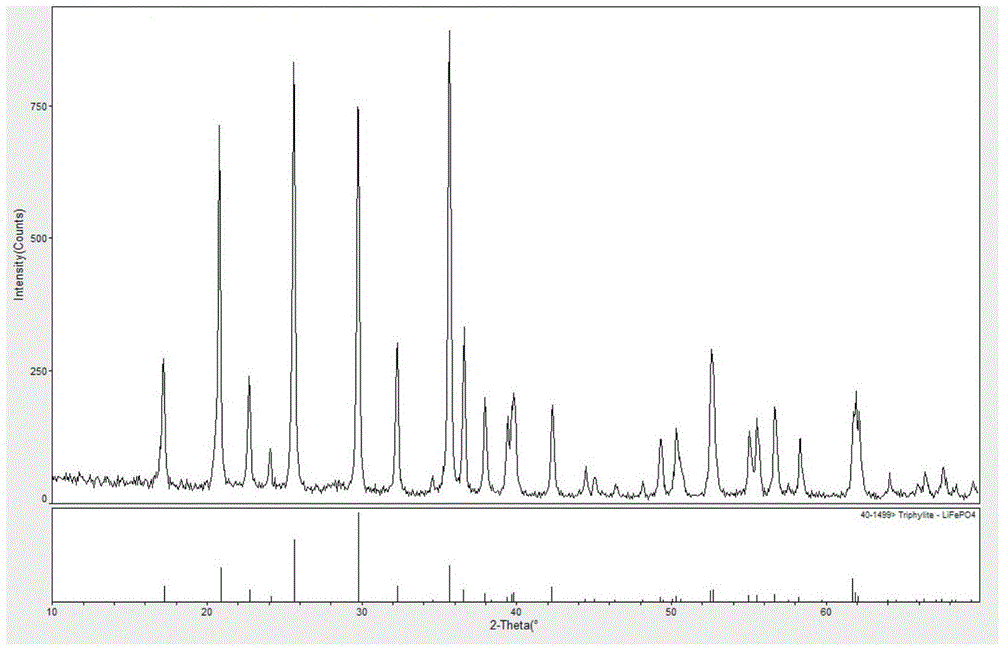

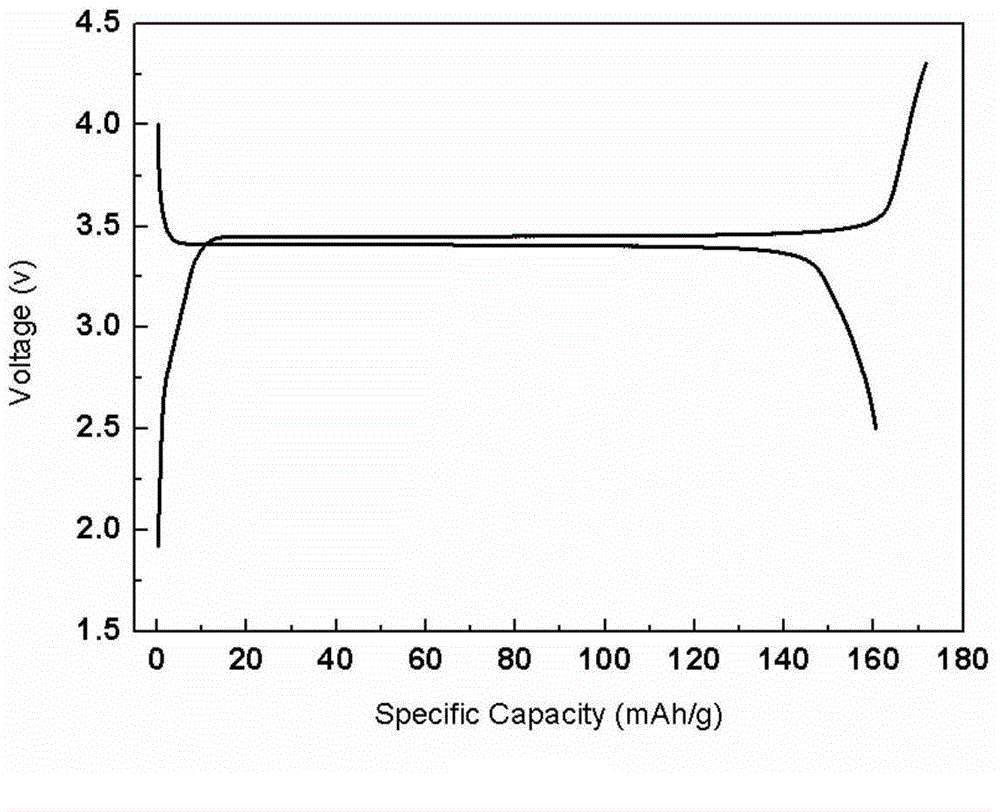

[0040]Weigh the basic raw materials ferrous phosphate, lithium hydroxide and phosphoric acid according to the ratio of element molar ratio Fe:Li:P=1.0:1.0:1.0, and weigh the amount of carbon source citric acid as 10% of the obtained lithium iron phosphate cathode material The above-mentioned raw materials are respectively dispersed in deionized water, the concentration of ferrous phosphate suspension is 1.5mol / L, and the concentration of lithium hydroxide, phosphoric acid and citric acid solution is respectively 1.0mol / L, 0.5mol / L and 0.5mol / L L, the volume ratio of the sum of the volume of the suspension and the solution to the liquid-phase reducing agent triethylene glycol is 1.0; add it to the liquid-phase reducing agent in the following order, and stir while adding: ferrous phosphate suspension-phosphoric acid solution -Citric acid solution-Lithium hydroxide solution, after mixing evenly, reflux reaction at 250°C for 8 hours, after cooling, perform centrifugation to achieve...

Embodiment 2

[0043] According to the ratio of element molar ratio Fe:Li:P=0.98:1.0:1.0, the basic raw material ferrous carbonate, lithium acetate and ammonium dihydrogen phosphate are weighed, and the amount of carbon source glucose is 10% of the obtained lithium iron phosphate positive electrode material. %; Disperse the above raw materials in deionized water respectively, the concentration of the ferrous carbonate suspension is 1.2mol / L, the concentrations of lithium acetate, ammonium dihydrogen phosphate and glucose solution are respectively 0.5mol / L, 1.0mol / L and 1.0 mol / L, the volume ratio of the sum of the volumes of the suspension and the solution to the liquid-phase reducing agent diethylene glycol is 0.5; add it to the liquid-phase reducing agent in the following order, and stir while adding: ferrous carbonate suspension- Ammonium dihydrogen phosphate solution-glucose solution-lithium acetate solution, after mixing evenly, reflux at 240°C for 12 hours, and then perform centrifugati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com