Suspension polymerization preparation method of polystyrene-coated ferriferrous oxide composite particle

A magnetic composite particle, ferric oxide technology, applied in the direction of iron oxide/iron hydroxide, organic material/organic magnetic material, ferrous oxide, etc. High requirements, poor dispersion and other problems, to achieve the effect of low price, simple coating operation and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

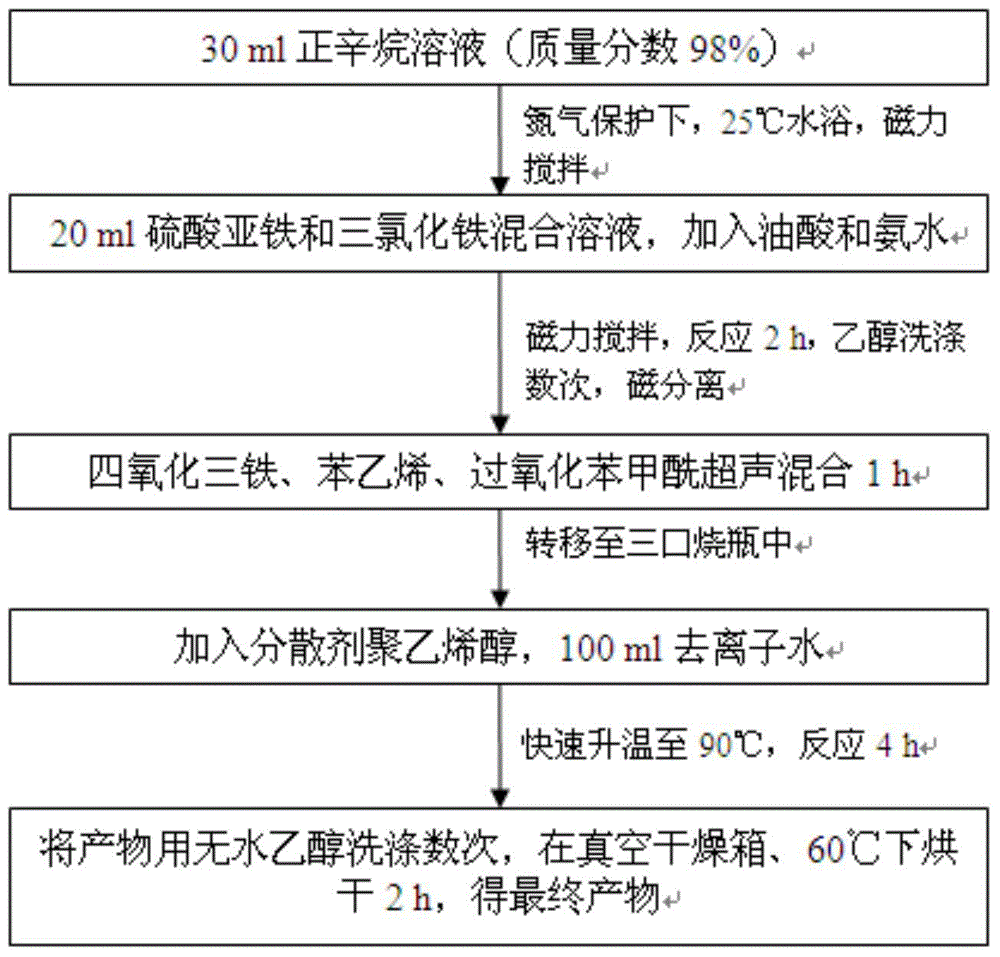

[0029] 1. Take 30ml of n-octane solution and add it to a three-necked flask, and place it in a water bath at 25°C;

[0030] 2. Weigh 0.444g (0.01mol) of ferrous sulfate and 0.864g (0.02mol) of ferric chloride to form a 20ml solution, and slowly add it into the three-necked flask with a syringe under sufficient stirring;

[0031] 3. Weigh 4.0g of sodium oleate to make 20mL solution, take 1ml of sodium oleate solution, and slowly add it into the three-neck flask with a syringe under sufficient stirring;

[0032] 4. Take 1.8 mL of ammonia water with a mass fraction of 27%, slowly add it into a three-necked flask with a syringe, age in a water bath for 2 hours, wash with ethanol for several times, and centrifuge at 10,000 rpm to obtain oil-soluble ferric oxide.

[0033] 5. Take 1 g of the above-mentioned oil-soluble ferric oxide, 16.91 ml of styrene (washed three times with 5% sodium hydroxide solution), and 0.9 g of benzoyl peroxide and ultrasonically mix them for 1 h and set asi...

Embodiment 2

[0037] 1. Take 30ml of n-octane solution and add it to a three-necked flask, and place it in a water bath at 25°C;

[0038] 2. Weigh 0.444g (0.01mol) of ferrous sulfate and 0.864g (0.02mol) of ferric chloride to form a 20ml solution, and slowly add it into the three-necked flask with a syringe under sufficient stirring;

[0039] 3. Weigh 4.0g of sodium oleate to make 20mL solution, take 1ml of sodium oleate solution, and slowly add it into the three-neck flask with a syringe under sufficient stirring;

[0040] 4. Take 1.8 mL of ammonia water with a mass fraction of 27%, slowly add it into a three-necked flask with a syringe, age in a water bath for 2 hours, wash with ethanol for several times, and centrifuge at 10,000 rpm to obtain oil-soluble ferric oxide.

[0041] 5. Take 1 g of the above-mentioned oil-soluble ferric oxide, 16.91 ml of styrene (washed three times with 5% sodium hydroxide solution) and 2.0 g of benzoyl peroxide and ultrasonically mix them for 1 h and set asid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com