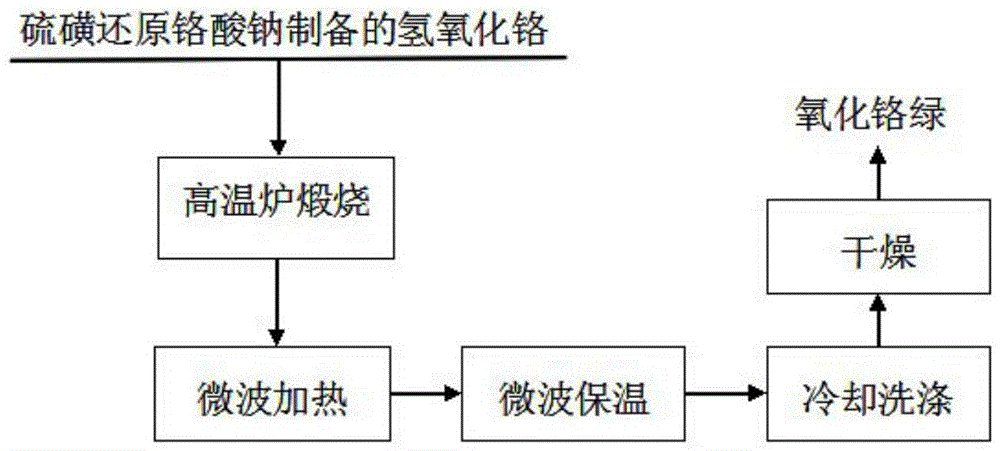

Method for preparing pigment-class chrome oxide green by adopting microwave heating

A microwave heating, chrome oxide green technology, applied in fibrous filler, dyeing physical treatment and other directions, can solve the problems of affecting quality and content, difficulty in industrialization, harsh production conditions, etc., to improve material properties, improve energy utilization, The effect of short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Sulfur powder and water with a weight ratio of 1:1 are wet ground into slurry, take 40kg of sulfur slurry and 100kg of sodium chromate alkaline solution, heat them to 150°C in the reactor, stir and react, and take samples during the reaction to detect the reaction solution When the content of hexavalent chromium in the medium is less than 0.05g / L, the reaction is stopped, and then aged for 0.5h, the reaction solution is filtered, and the filter cake is washed in multi-stage countercurrent with 90°C water until The content of sodium thiosulfate in the filtrate is less than 0.05g / L, neutralize the washed precipitate with sulfuric acid to a pH value of 7.0, and then wash with a filter, remove the supernatant after the washed slurry is precipitated, and then centrifuge Dehydration to obtain chromium hydroxide, chromium hydroxide was calcined at 1300°C for 3 hours, then washed and dried to obtain chromium oxide.

[0027] Put 2.5kg of chromium oxide in a microwave sintering f...

Embodiment 2

[0029] Using the same method as in Example 1 to prepare chromium oxide, place 1.9kg of chromium oxide in a microwave sintering furnace, using a microwave frequency of 2450MHz, first raise the temperature to 100°C at a heating rate of 100°C / min, and then use 100°C as the temperature increase range , 50°C / min is the heating rate for heating and heating. Each temperature point is kept for 10 minutes until the temperature rises to 1000°C, and the heat is kept for 85 minutes. Dry to obtain 1.8kg pigment grade chromium oxide green, after testing its Cr 2 o 3 The content is 99.1wt%, meeting the standard of pigment-grade chromium oxide green.

Embodiment 3

[0031]Using the same method as in Example 1 to prepare chromium oxide, put 3.2kg of chromium oxide in a microwave sintering furnace, using a microwave frequency of 915MHz, first raise the temperature to 100°C at a heating rate of 50°C / min, and then use 100°C as the temperature increase range 100°C / min is the heating rate for heating and heating. Each temperature point is kept warm for 5 minutes until the temperature rises to 1200°C, and the heat is kept for 60 minutes. Dry to obtain 3.0kg pigment grade chromium oxide green, after testing its Cr 2 o 3 The content is 99.5wt%, meeting the standard of pigment-grade chromium oxide green.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com