A hydrate-based method for separating CO from biogas 2 method and device

A technology of hydrate and hydrate slurry, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of high energy consumption, large CH4 consumption, complicated process, etc., achieve uniform temperature, reduce heat loss, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

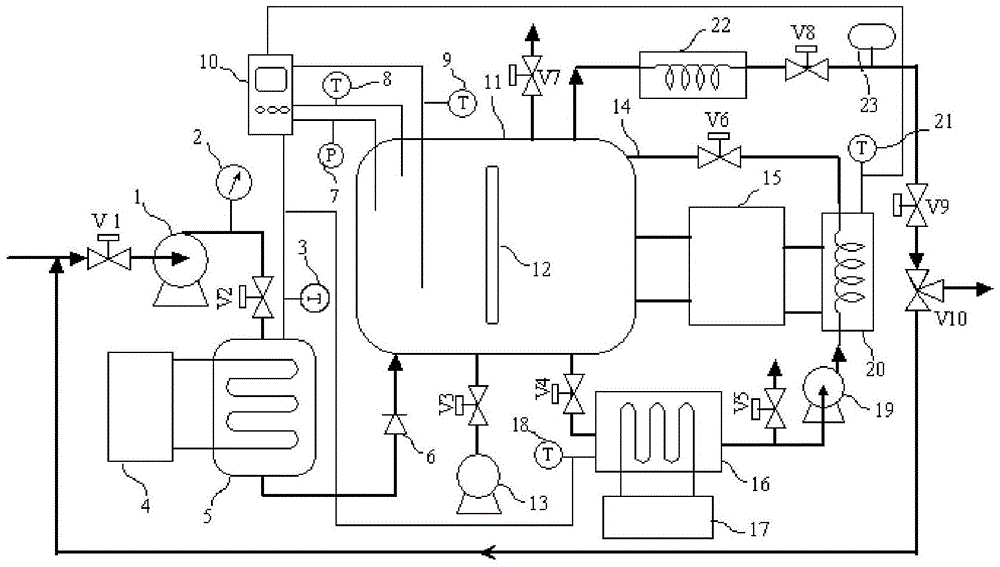

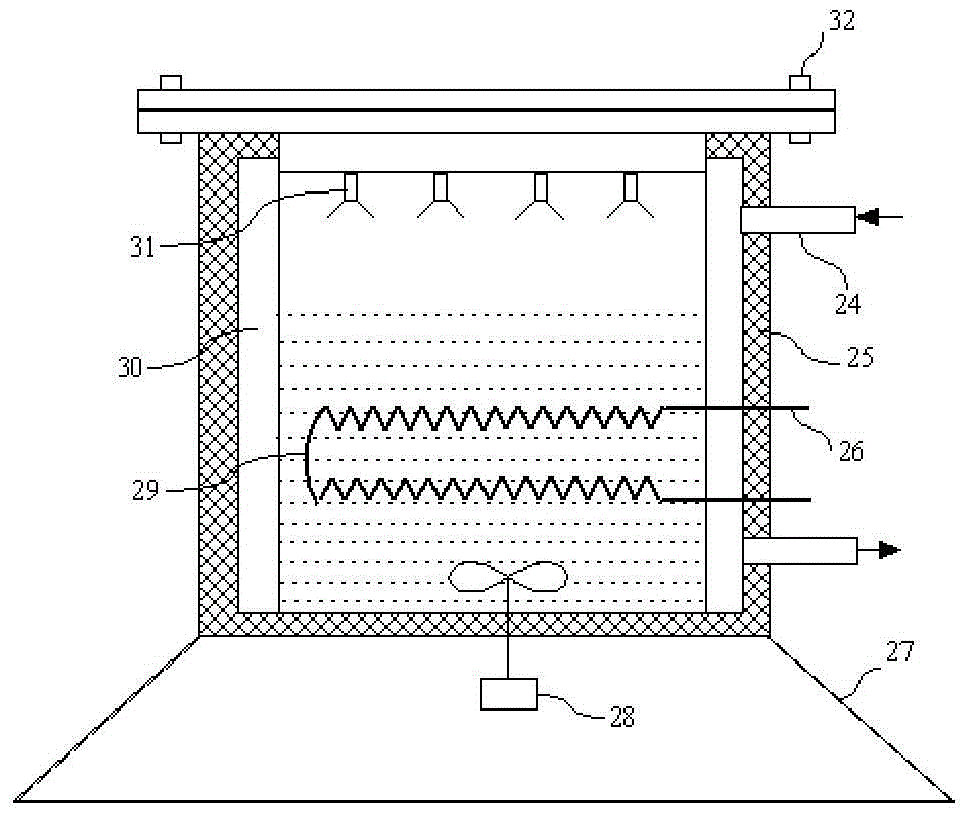

Method used

Image

Examples

Embodiment 1

[0050] Take raw gas samples, where CH 4 The content is 60%, CO 2 The content is 40%, and the SDS aqueous solution with a mass concentration of 300ppm is selected. When the temperature of the reactor is 278K and the pressure is 5MPa, after 30 minutes of reaction, the CH in the gas phase of the reactor 4 content increased to 90.8%, CO 2 The content is 9.2%, and after another cycle, the CH in the gas phase of the reactor 4 The content is 97.1%, CO 2 The content is 2.9%.

Embodiment 2

[0052] Take raw gas samples, where CH 4 Content is 50%, CO 2 The content is 50%, and the TBAB aqueous solution with a mass concentration of 0.05% is selected. When the temperature of the reactor is 276K and the pressure is 3.5MPa, after 30 minutes of reaction, CH in the gas phase of the reactor 4 The content is 88.8%, CO 2 The content of CH is 11.2%. After the hydrate is decomposed, the raw material gas goes through 2 cycles, and the CH in the gas phase of the reactor 4 The content is 95.3%, CO 2 The content is 4.7%.

Embodiment 3

[0054] Take raw gas samples, where CH 4 Content is 40%, CO 2 The content is 59%, H 2 The S content is 1%, and the mixed aqueous solution of THF with a mass concentration of 1% and 100ppm of SDS is selected. The temperature of the reactor is 278K, and the pressure is 2.5MPa. After 1 hour of reaction, CH in the gas phase in the reactor 4 The content is 85.5%, CO 2 The content is 13.9%, H 2 With an S content of 0.6%, after 3 cycles, CH 4 The content is 95.2%, CO 2 The content is 4.2%, H 2 The S content is 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com