Amino resin composition for flame-retardant wet curtain and preparation method and application thereof

A technology of amino resin and composition, which is applied in the direction of plant fiber, textile and paper making, non-fiber pulp addition, etc. It can solve the problems of poor water resistance of amino resin, affecting the use of wet curtains, and poor water resistance, so as to achieve flame retardancy Significant effect, good performance and water resistance, effect of improving performance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

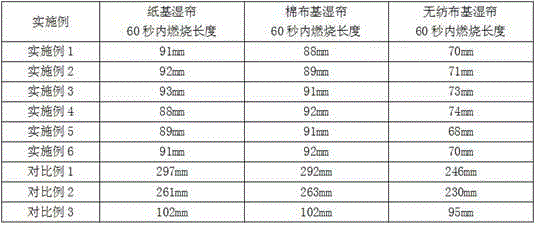

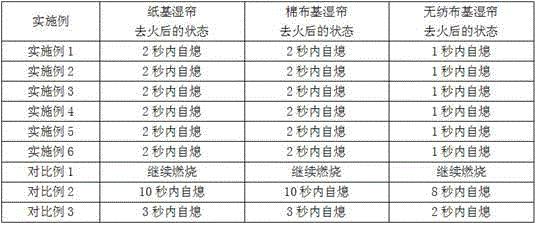

Examples

Embodiment 1

[0019] The amino resin composition for the flame retardant wet curtain of this embodiment is composed of the following raw materials in parts by weight: amino resin 100, flame retardant resin 150 and additive 310, and the additive is composed of: water 100, sodium dodecylbenzene sulfonate 10 and methanol 200.

[0020] The preparation method of the amino resin composition for the flame retardant wet curtain of this embodiment is as follows:

[0021] 1) Preparation of flame retardant resin: put 1000g phenol, 200g triphenyl phosphate, 300g ethylene glycol, 300g urea, 50g sulfuric acid (10% aqueous solution) into the reactor, raise the temperature to 120°C for 2 hours, then cool down to 70°C, Add 1800g formaldehyde (37% aqueous solution) in four times at the same time interval within 2 hours according to the weight ratio of 10%, 20%, 30% and 40%, add 50g sodium hydroxide, react at constant temperature for 2 hours, and vacuum dehydrate until the water content is 10~ 20%, dilut...

Embodiment 2

[0026] The amino resin composition for the flame retardant wet curtain of this embodiment consists of the following raw materials in parts by weight: amino resin 100, flame retardant resin 100 and additive 115, and the additive consists of: sodium lauryl sulfate 10, sodium sulfate 5 and Ethanol 100.

[0027] The preparation method of the amino resin composition for the flame retardant wet curtain of this embodiment is as follows:

[0028] 1) Preparation of flame retardant resin: put 1000g of o-cresol, 600g of triphenyl phosphite, 500g of glycerol, 700g of dicyandiamide, and 70g of hydrochloric acid (10% aqueous solution) into the reaction kettle, heat up to 100°C for 4 hours, Cool down to 60°C, add 1900g of formaldehyde (37% aqueous solution) in four times at the same time interval within 2 hours according to the weight ratio of 10%, 20%, 30% and 40%, add 60g of potassium hydroxide, react at constant temperature for 3 hours, vacuum Dehydrate to 10-20% moisture, di...

Embodiment 3

[0033] The amino resin composition for the flame retardant wet curtain of this embodiment is composed of the following raw materials in parts by weight: amino resin 100, flame retardant resin 200 and additive 230, and the additive is composed of: Tween 80 20, sodium chloride 10 and ethylene glycol Alcohol 200.

[0034] The preparation method of the amino resin composition for the flame retardant wet curtain of this embodiment is as follows:

[0035] 1) Preparation of flame retardant resin: put 1000g salicylic acid, 500g dimethyl phosphate, 500g glucose, 500g melamine, 90g phenolsulfonic acid (10% aqueous solution) into the reactor, raise the temperature to 130°C for 2 hours, cool down to 50°C, at the same time interval within 3 hours, add 700g of paraformaldehyde (96%) in four times according to the weight ratio of 10%, 20%, 30%, and 40%, add 100g of triethylamine, and react at constant temperature for 1 to 5 hours , vacuum dehydrated to 10-20% moisture, diluted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com