Ferrocene group-containing aniline derivative polymer and use thereof

An aniline derivative and ferrocene-based technology, applied in the field of aniline derivative polymers, can solve the problems of unstable voltage platform and poor cycle stability, achieve a significant charge-discharge voltage platform, and improve the charge-discharge voltage. Platform and loop performance, effect of increasing spatial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

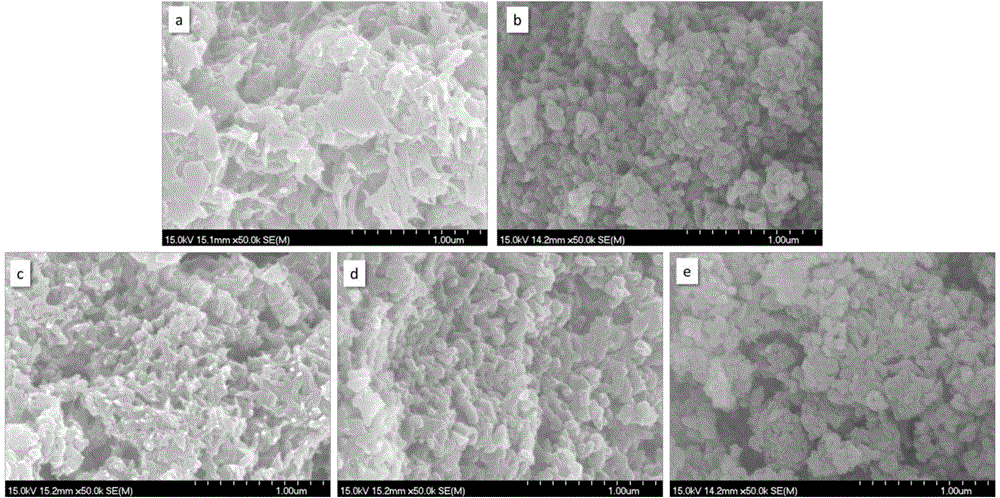

[0055] Example 1: PAnFc, P(An-co-AnFc)(2:1), P(An-co-AnFc)(3:1), P(An-co-AnFc)(5:1)

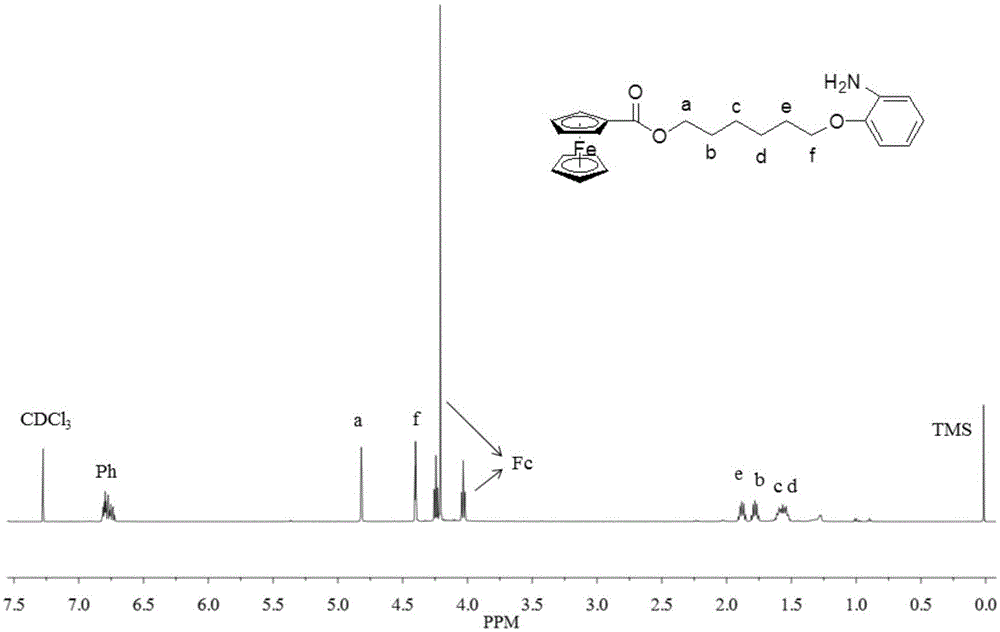

[0056] Synthesis of 6-(2-nitrophenoxy)hexanol: add 40mLN,N-dimethylformamide to a pre-dried 250mL three-neck flask, then add o-nitrophenol (2.78g), 6- Chlorohexanol (3.28g) and sodium hydroxide (1.2g) were stirred, the temperature of the reaction solution was raised to 60°C, and the reaction was continuously stirred for 72h. At the end of the reaction, extract the reaction mixture with dichloromethane to obtain the oil phase extract and dry it with anhydrous magnesium sulfate powder, then remove the solvent with a rotary evaporator, and the remaining product is separated and purified by column chromatography. The stationary phase is selected from 300 mesh silica gel. The phase was eluted with n-hexane / ethyl acetate (volume ratio 100:1), and the eluent was evaporated to remove the solvent to finally obtain 3.73 g of 6-(2-nitrophenoxy)hexanol with a yield of 78%. The product was Light green li...

Embodiment 2

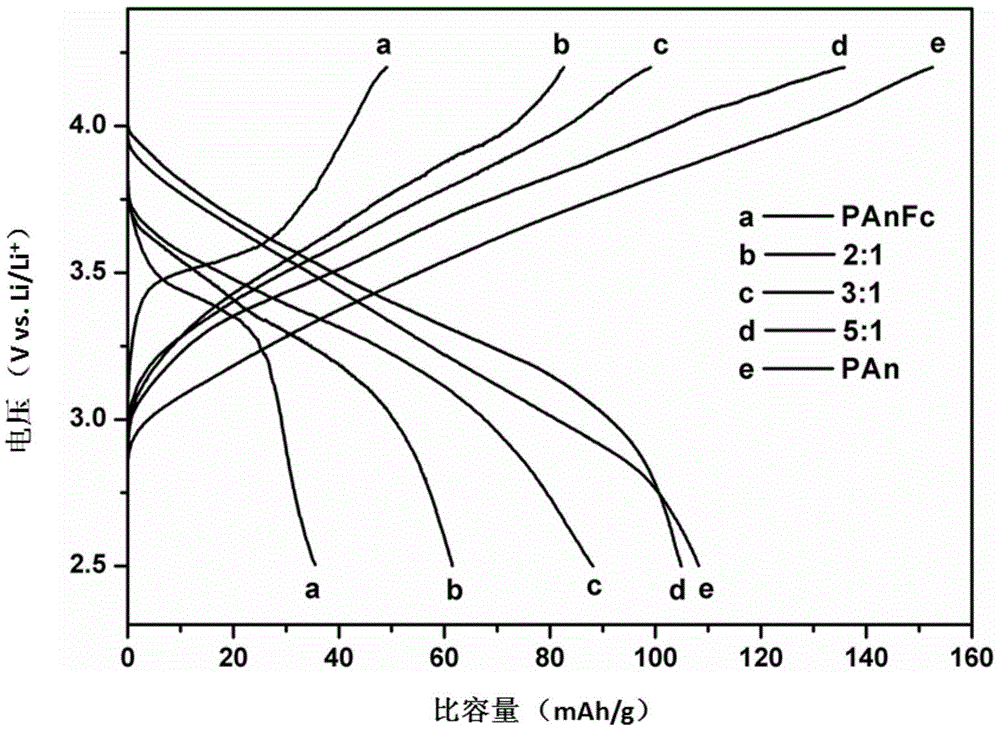

[0064] PAnFc, P(An-co-AnFc)(2:1), P(An-co-AnFc)(3:1), P(An-co-AnFc)(5:1) prepared in Example 1 respectively ) polymer respectively as the active material of positive electrode material, prepare lithium-ion battery according to the following steps:

[0065] a) Weigh 0.01 g of binder powder and disperse it in 1 mL of N-methylpyrrolidone solvent, seal and stir, and slightly heat to obtain a binder slurry.

[0066] b) Weigh 0.04g of acetylene black and 0.05g of the prepared polymer powder and mix them evenly.

[0067] c) Pour the mixture in b) into the bonding slurry in a), then add 3mL of N-methylpyrrolidone, stir and mix evenly to obtain a mixed slurry with moderate viscosity.

[0068] d) The slurry in c) is uniformly coated on the aluminum foil, and placed in an oven at 60° C. for 24 hours in vacuum to obtain a positive electrode sheet.

[0069] e) With the positive electrode sheet prepared in d) as the positive electrode, the metal lithium sheet as the negative electrode, 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com