C3-fraction liquid phase selective hydrogenation catalyst as well as preparation method and application thereof

A selective hydrogenation and catalyst technology, applied in hydrogenation hydrocarbon production, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex system, many control and influencing factors, etc. Uniform composition, narrow particle size distribution, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

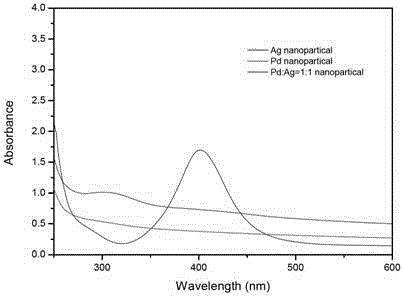

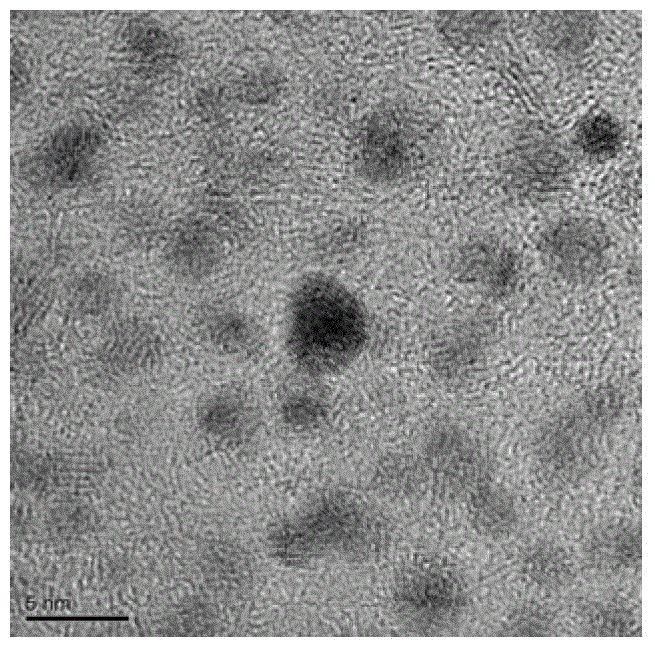

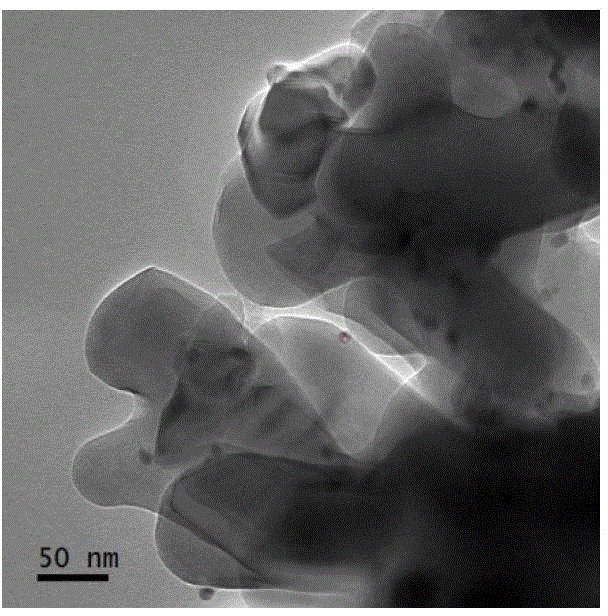

Method used

Image

Examples

Embodiment 1

[0035]① Pipette 40mgPd / ml[Pd(NH 3 ) 4 ](NO 3 ) 2 Solution 5ml, 100mgAg / ml [Ag(NH 3 ) 4 ]NO 3 Solution 6ml, weigh 1500mg of polyvinylpyrrolidone (PVP), dilute to 15g with deionized aqueous solution;

[0036] ②In a constant temperature water bath at 70°C, add 10g of non-ionic surfactant Brij35 and 10g of oil phase isooctane in a 100ml volumetric flask, stir for 4 hours by magnetic force, then add ① into ② and stir for 30 minutes to obtain a W / O microemulsion ;

[0037] 3. add reducing agent hydrazine hydrate, add in the microemulsion according to the mol ratio of metal salt and reducing agent in the water phase as 1:4, carry out reduction reaction, react for 4 hours;

[0038] ④ Weigh spherical SiO 2 Carrier 100g, impregnated with the microemulsion prepared above;

[0039] ⑤ Dry and roast the carrier impregnated with the above-mentioned microemulsion to prepare the catalyst, and obtain the catalyst GB-1, wherein the Pd-Ag alloy content is 0.8% of the total mass, and the ...

Embodiment 2

[0041] ① Pipette 10mgPd / ml[(NH 4 ) 2 Pd]Cl 4 Solution 5ml, 20mgAg / ml HAuCl 4 Solution 2.5ml, weigh 400mg polyacrylamide (PAM), dilute to 20g with deionized aqueous solution;

[0042] ②In a constant temperature water bath at 60°C, add 5g of anionic surfactant AOT, 6g of nonionic surfactant Brij72, and 15g of oil phase n-octane in a 100ml volumetric flask, stir magnetically for 2h, then add ① into ② and stir for 1h to obtain W / O microemulsion;

[0043] 3. add reducing agent sodium borohydride, add in the molar ratio of metal salt and reducing agent according to the water phase as 1:8, carry out reduction reaction, react for 8 hours;

[0044] ④ Weigh spherical TiO 2 Carrier 100g, impregnated with the microemulsion prepared above;

[0045] ⑤ Dried and calcined the carrier impregnated with the above-mentioned microemulsion to prepare the catalyst, and obtained the catalyst GB-2, wherein the Pd-Au alloy content was 0.1% of the total mass, and the mass ratio of Pd:Au was 1:1 ....

Embodiment 3

[0047] ① Pipette 20mgPd / mlK 2 [Pd(CN) 4 ] solution 5ml, 300mgAg / mlKAgCN 2 0.5ml of aqueous solution, weigh 120mg of PVP, and dilute to 12g with deionized aqueous solution;

[0048] ②In a constant temperature water bath at 45°C, in a 100ml volumetric flask, add 10g of non-ionic surfactant Brij30, 12g of oil phase n-nonane, and magnetically stir for 4h, then add ① into ② and stir for 20min to obtain a W / O microemulsion;

[0049] ③Add reducing agent hydrazine hydrate, add in the microemulsion according to the molar ratio of metal salt and reducing agent in the water phase as 1:8, carry out reduction reaction, and react for 1 hour;

[0050] ④ Weigh columnar Al 2 o 3 Carrier 100g, impregnated with the microemulsion prepared above;

[0051] ⑤ Dried the carrier impregnated with the above microemulsion in ④ at 110°C for 12 hours, and roasted at high temperature to prepare the catalyst. The obtained catalyst GB-3, wherein the Pd-Ag alloy content was 0.25% of the total mass, Pd:Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com