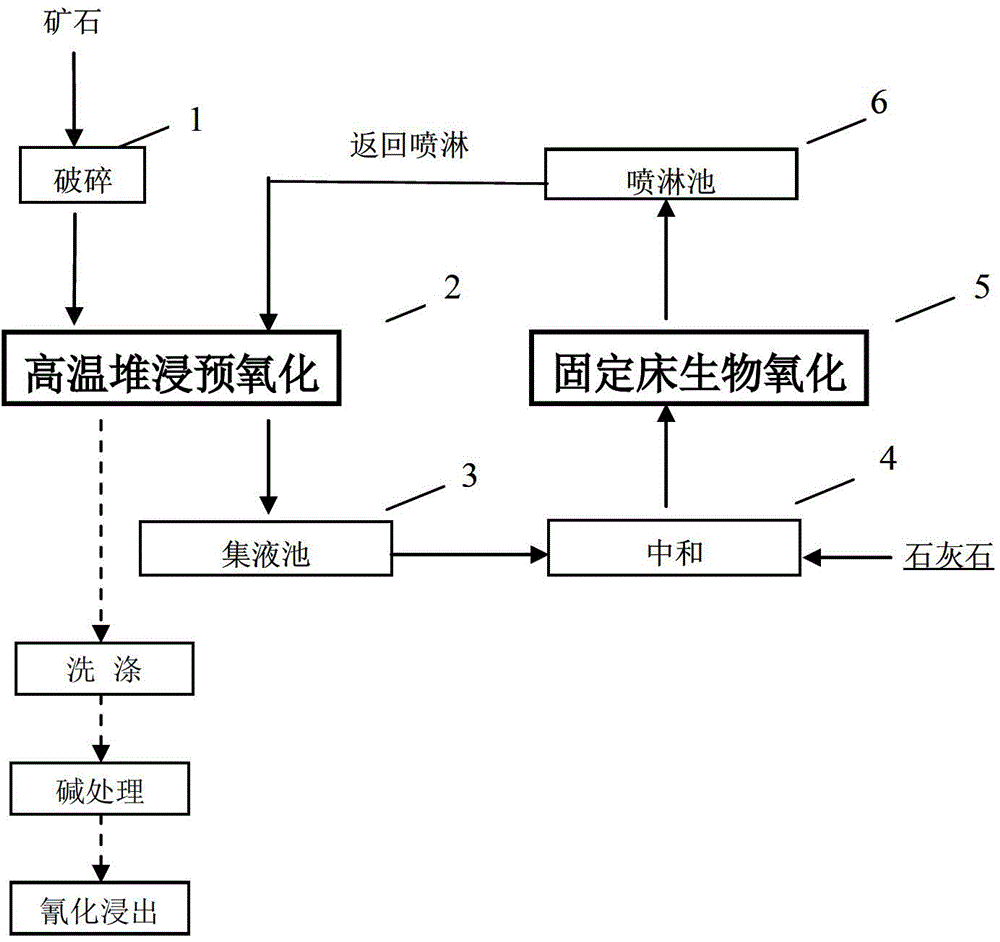

Heap-leaching based biological pre-oxidation method for refractory gold ore

A refractory gold ore pre-oxidation technology, applied in the direction of improving process efficiency, can solve the problem of rapid dissolution of difficult ferrous iron, and achieve the effects of improving oxidation efficiency, reducing production costs, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the biocolumn leaching oxidation test of pyrite concentrate, the pyrite content is 94%, and the main element components are: Fe 46.9%, TS 44.47%, Si 5.51%, Al 2.28%. The raw ore is selected-crushed-flotation to obtain pure pyrite, and then the -20mm concentrate is screened and packed into a column after rod milling and vibration. The inner diameter of the leaching column is 60mm and the effective height is 400mm. , the peristaltic pump flow rate is 150L / m 2 h. The temperature of the column leaching test is 60°C, and the temperature of the leaching solution is 55°C to 60°C. When the pH value of the oxidation solution is lower than 1.5, use limestone to neutralize, adjust the pH to 1.5-1.7, and the initial total iron concentration is 3.89g / L. In the biological oxidation fixed bed for adsorbing bacterial species, the temperature of the fixed bed is 30-35°C. After being oxidized by microorganisms in the fixed bed, the oxidation-reduction potential is controlled at 890...

Embodiment 2

[0034] In the industrial test of bioheap leaching pre-oxidation of a low-grade refractory gold ore, the ore contained 5.3% sulfur, 0.2% arsenic, and the gold grade was 2.3g / t. Crush the ore to -20mm and build a heap with a height of 20 meters. Intermittent spraying is adopted, the spraying time is 6 hours a day, and the spraying intensity is 6L / m 2 h; when the temperature of the leachate is lower than 45°C, reduce the spraying time and maintain the temperature of the leachate at 50°C to 55°C. In the initial stage of leaching, the acidic pit water of the mine is used for spraying, and the leachate is oxidized by the fixed bed of activated carbon as the main carrier and then returned to the spray pool for circular spraying; the acidophilic bacteria in the fixed bed of activated carbon are mainly from the iron-sulfur in the pit water. Oxidizing bacteria (including Spirulina ferrooxidans and Thiobacillus ferrooxidans, etc.); when the pH value of the leachate is lower than 1.5, us...

Embodiment 3

[0036] In the industrial test of bioheap leaching pre-oxidation of a low-grade refractory gold ore, the ore contained 5.3% sulfur, 0.2% arsenic, and the gold grade was 2.3g / t. Crush the ore to -20mm and build a heap with a height of 15 meters. Intermittent spraying is adopted, the spraying time is 6 hours a day, and the spraying intensity is 6L / m 2 h; when the leachate temperature is lower than 45°C, reduce the spraying time and maintain the leachate temperature at 45-50°C. In the initial stage of leaching, the acidic pit water of the mine is used for spraying, and the leachate is oxidized by the fixed bed of activated carbon as the main carrier and then returned to the spray pool for circular spraying; the acidophilic bacteria in the fixed bed of activated carbon mainly come from the iron-sulfur in the pit water. Oxidizing bacteria (including Spirulina ferrooxidans and Thiobacillus ferrooxidans, etc.); when the pH value of the leachate is lower than 1.5, use limestone to neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com