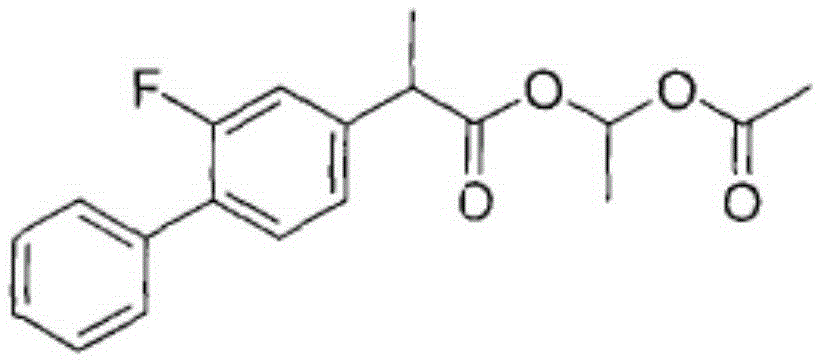

A kind of pharmaceutical composition of flurbiprofen axetil

A flurbiprofen axetil and composition technology, which is applied in the field of flurbiprofen axetil pharmaceutical compositions, can solve the problems of difficult storage, easy oxidation, particle size increase, etc., and achieve non-degradable, good stability, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

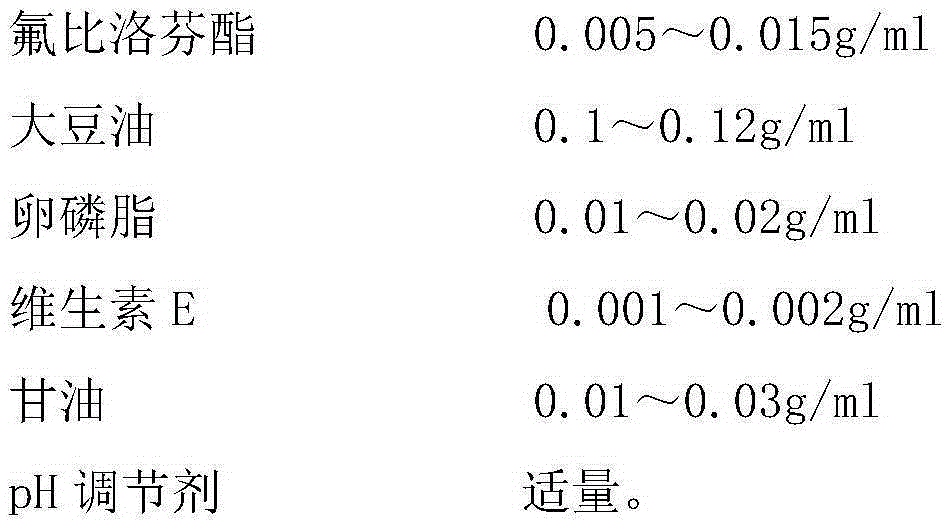

[0039] prescription:

[0040]

[0041] Preparation Process:

[0042] 1) Under nitrogen protection, soybean oil and lecithin are heated to 70°C, and while stirring, flurbiprofen axetil and vitamin E are added to dissolve to obtain an oil phase;

[0043] 2) Under nitrogen protection, add glycerol to part of the water for injection, dissolve, and obtain an aqueous phase;

[0044] 3) Under nitrogen protection, add the oil phase of step 1) into the water phase of step 2), disperse by high-speed shearing for 20 minutes, the shearing speed is 6000rpm, then adjust pH=4.5 with a pH adjuster, and add water for injection Dilute to 1000ml, stir to get colostrum;

[0045] 4) Under the protection of nitrogen, add the colostrum into the high-pressure homogenizer, set the high-pressure homogenization pressure to 800bar, and perform high-pressure homogenization 3 times. During the high-pressure homogenization process, adjust the flow of condensed water and control the temperature of the e...

Embodiment 2

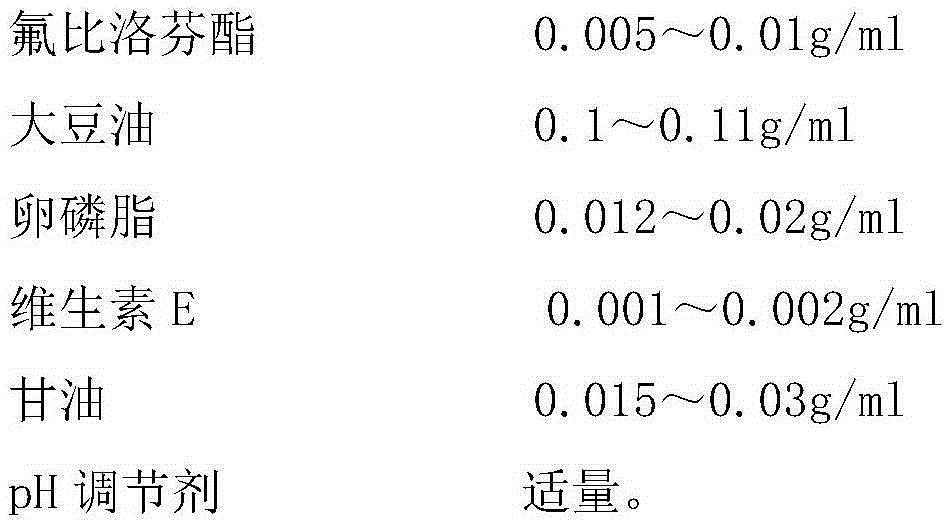

[0049] prescription:

[0050]

[0051] Preparation Process:

[0052] 1) Under nitrogen protection, soybean oil and lecithin were heated to 75°C, and while stirring, flurbiprofen axetil and vitamin E were added to dissolve to obtain an oil phase;

[0053] 2) Under nitrogen protection, add glycerol to part of the water for injection, dissolve, and obtain an aqueous phase;

[0054] 3) Under nitrogen protection, add the oil phase of step 1) to the water phase of step 2), disperse by high-speed shearing for 30 minutes, the shearing speed is 8000rpm, then adjust pH=6.5 with a pH adjuster, and add water for injection Dilute the volume to 1000ml and stir to obtain colostrum; the pH adjusting agent is disodium hydrogen phosphate and citric acid buffer, and the dosage is to make the injection pH=6.5, wherein disodium hydrogen phosphate and citric acid The molar ratio is 4:1;

[0055] 4) Under nitrogen protection, add colostrum into the high-pressure homogenizer, set the high-pressur...

Embodiment 3

[0059] prescription:

[0060]

[0061] Preparation Process:

[0062] 1) Under nitrogen protection, soybean oil and lecithin are heated to 72°C, and while stirring, flurbiprofen axetil and vitamin E are added to dissolve to obtain an oil phase;

[0063] 2) Under nitrogen protection, add glycerol to part of the water for injection, dissolve, and obtain an aqueous phase;

[0064] 3) Under nitrogen protection, add the oil phase of step 1) to the water phase of step 2), disperse by high-speed shearing for 25 minutes, the shearing speed is 7000rpm, then adjust pH=5.5 with a pH regulator, and add water for injection Dilute to 1000ml, stir to get colostrum;

[0065] 4) Under nitrogen protection, add colostrum into the high-pressure homogenizer, set the high-pressure homogenization pressure to 800bar, and perform high-pressure homogenization 4 times. During the high-pressure homogenization process, adjust the flow of condensed water and control the temperature of the emulsion to n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com