Preparation method of graphene, and graphene

A graphene and acrylate technology, applied in the field of carbon materials, can solve problems such as easy pollution of the environment, graphene surface damage, difficulty in meeting large-scale needs, etc., and achieve the effect of simple process, high unit yield, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a kind of preparation method of graphene, comprises the following steps: A) metal catalyst is mixed with carbon source, carries out adsorption, obtains the carbon source that adsorbs metal catalyst, and described carbon source comprises ion exchange resin, carbon material, One or more of biomass materials and gel materials; B) heating the reducing agent and the carbon source adsorbed with the metal catalyst in the step A) to obtain graphene.

[0047]The preparation method of graphene provided by the invention does not use strong acid, oxidant and other raw materials that seriously pollute the environment, has little environmental pollution, and is beneficial to the industrialization of graphene.

[0048] In the invention, the metal catalyst is mixed with the carbon source for adsorption to obtain the carbon source with the metal catalyst adsorbed. In the present invention, the carbon source is preferably mixed with a purification reagent for purif...

Embodiment 1

[0094] Take 100g of styrene-diethylene polyresin and crush it through a 200-mesh sieve, add it to a KOH solution with a mass fraction of 5%, stir and impregnate for 12 hours, filter and dry; add the dried ion-exchange resin to 1L of 0.05mol / L In the potassium ferricyanide solution, stir evenly, let stand for 6 hours, filter and dry; add the resin that adsorbs the metal ion catalyst into the solution containing 400g KOH, let stand for 6 hours, dry and pulverize; then mix the pulverized product with 5g aluminum powder Evenly, put it in a tube furnace, in an argon atmosphere, raise the temperature to 850°C at a heating rate of 4°C / min, keep it for 2 hours, take it out after naturally cooling down, pickle, filter, and dry in sequence to obtain graphene. The specific yield is 35%.

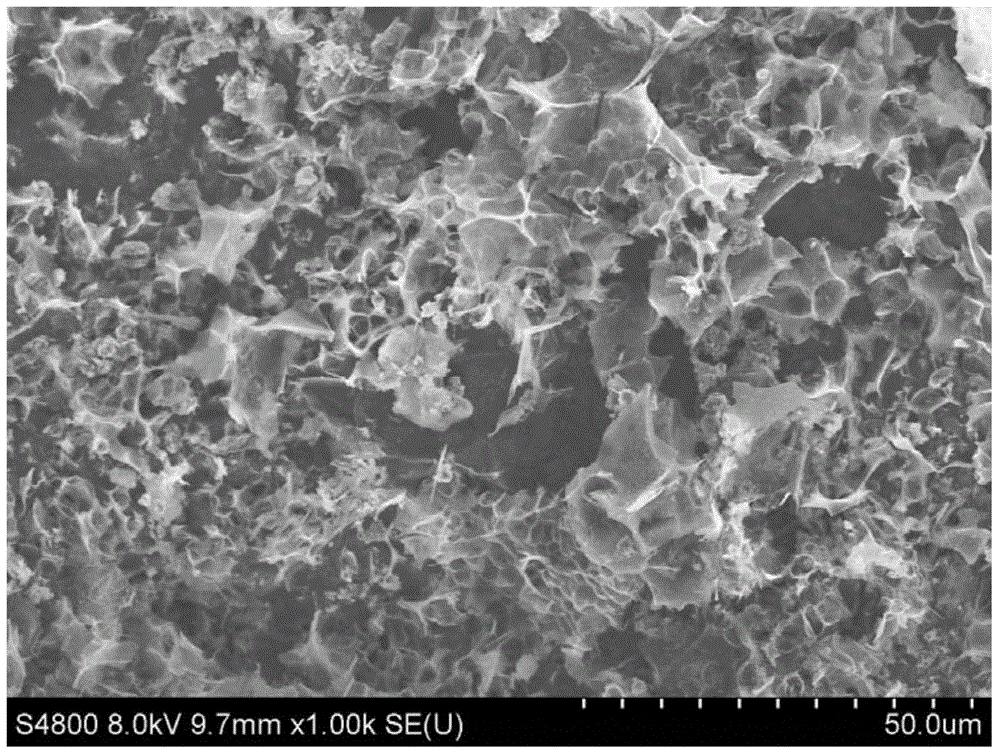

[0095] The present invention has carried out scanning electron microscope (SEM) test to the graphene that the present embodiment obtains, and the result is as follows figure 1 shown. figure 1 It is th...

Embodiment 2

[0097] Take 100g of activated carbon and crush it through a 200-mesh sieve, put it into 10% ozone gas for 12 hours and take it out; add it to 1L of 0.05mol / L nickel acetate solution, stir evenly, let it stand for 6 hours, filter and dry; put the activated carbon adsorbed metal ion catalyst Add it into the solution containing 400g KOH, let it stand for 6h, dry and pulverize it; then place the pulverized product in a tube furnace, in a hydrogen atmosphere, raise the temperature to 850℃ at a heating rate of 4℃ / min, and keep it for 2h, Take it out after natural cooling, pickle, filter, and dry in sequence to obtain graphene with a unit yield of 40%.

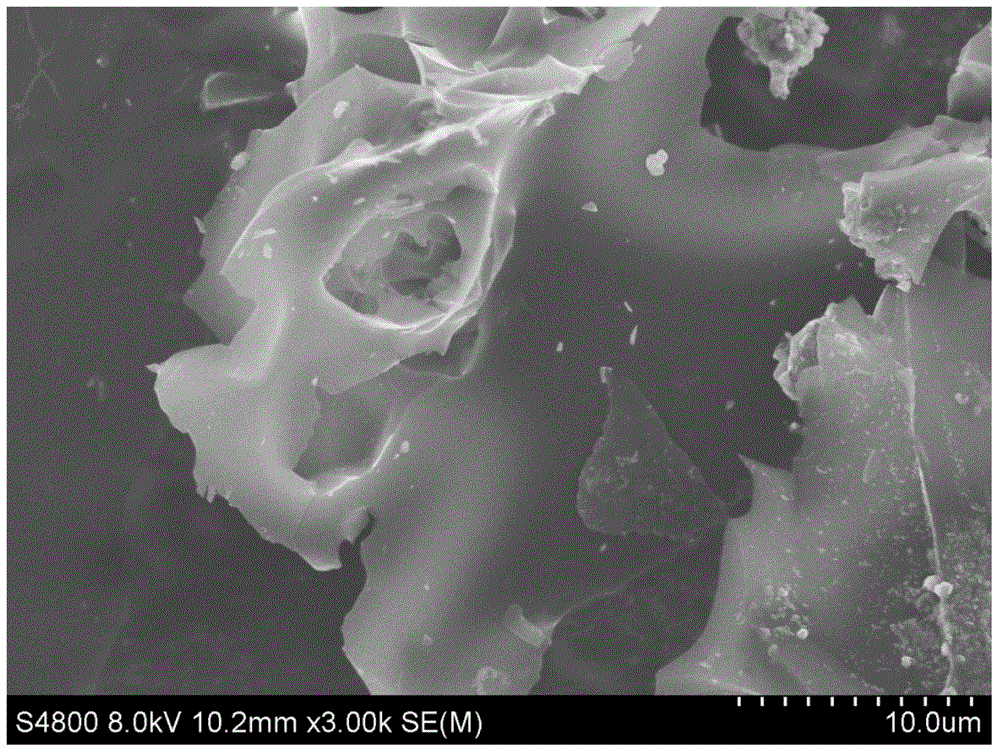

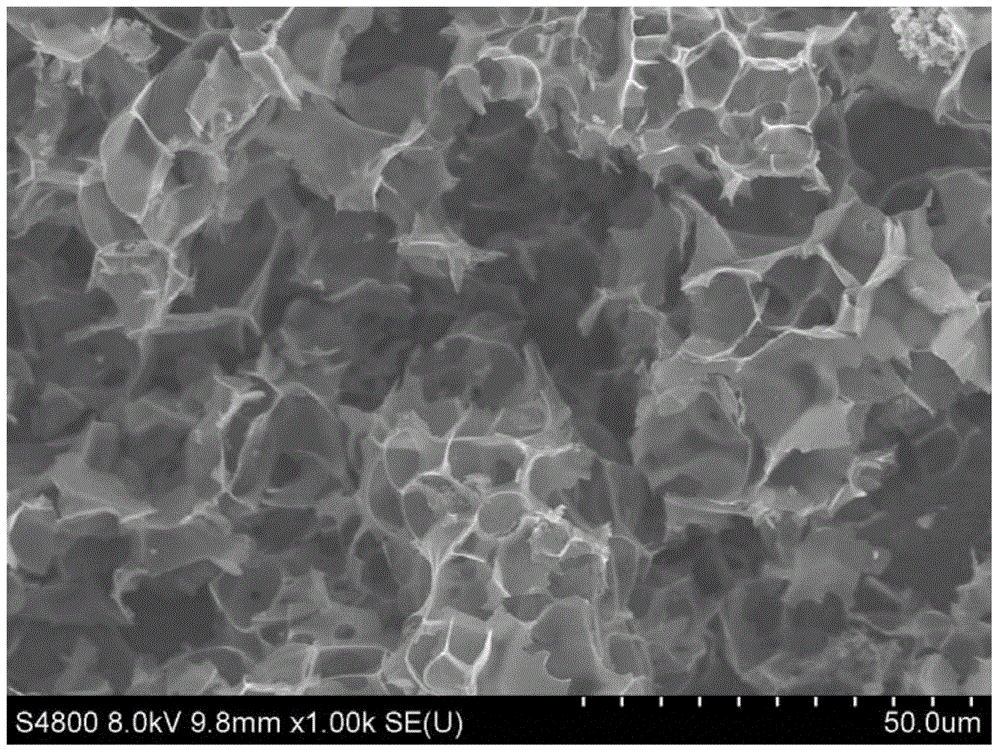

[0098] The present invention has carried out scanning electron microscope (SEM) test to the graphene that the present embodiment obtains, and the result is as follows figure 2 shown. figure 2 It is the SEM image of the graphene obtained in Example 2 of the present invention. Depend on figure 2 It can be seen that the graphene o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com