Method for preparing environment-friendly low-smoke flame retardant powdered butadiene styrene rubber

A technology of powdered styrene-butadiene rubber and styrene-butadiene latex, which is applied in the field of preparation of low-smoke and flame-retardant powdered styrene-butadiene rubber, and can solve problems such as uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

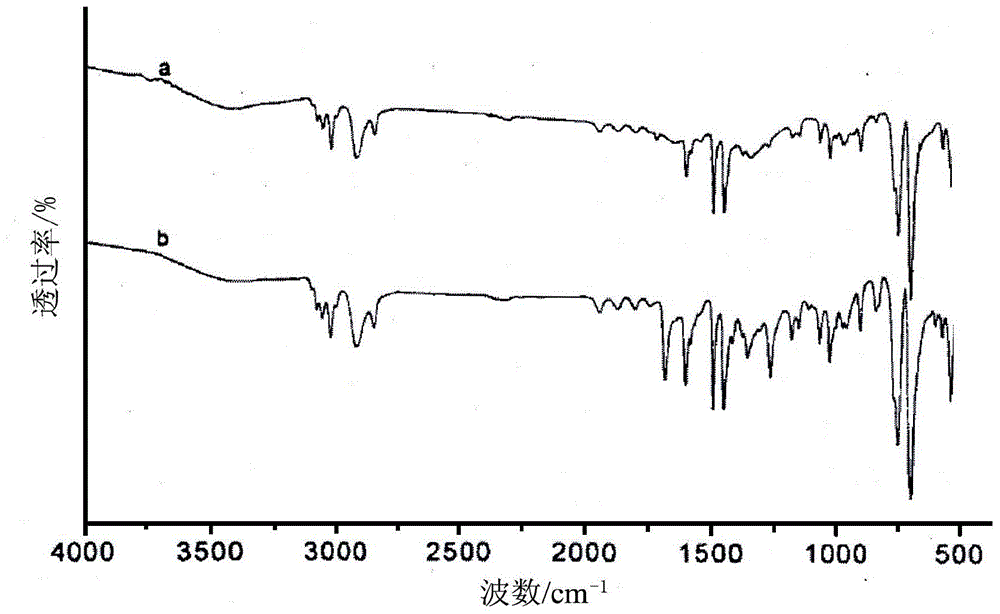

[0033] (1) Preparation of acylated styrene-butadiene latex: 100 parts of styrene-butadiene latex SBR1500, 2 parts of sodium dodecylbenzenesulfonate, 5.5 parts of CS 2 , then stirred and heated, and when the temperature of the polymerization kettle rose to 40°C, quickly added 0.05 parts of AlCl 3 , until the system turns orange-red, add 5 parts of phthalic anhydride, then react at 45°C for 2 hours, and finally add 12 parts by mass of 2.4% dilute hydrochloric acid aqueous solution to terminate the reaction, suction filter and wash to obtain phthalic anhydride SBR latex a. Sampling analysis: the measured degree of acetylation of acylated styrene-butadiene latex is 13.1%.

[0034] (2) Preparation of functionalized expandable graphite: Add 1.5 parts of NDZ-101 coupling agent, 60 parts of water, and 6 parts of ethanol into the polymerization kettle and stir and mix evenly. Adjust the pH of the system with a mass concentration of 0.05% oxalic acid solution to 5. Then add 100 parts ...

Embodiment 2

[0037] (1) Preparation of acylated styrene-butadiene latex: same as Example 1.

[0038] (2) Preparation of functionalized expandable graphite: Same as Example 1.

[0039] (3) Preparation of flame-retardant powdered styrene-butadiene rubber: Take 100 parts of acylated styrene-butadiene latex a, 4 parts of functionalized expandable graphite a, and 50 parts of water into the coagulation kettle and stir and mix for 30 minutes, then heat up to 55 °C, Add 2.5 parts of potassium oleate and 3.5 parts of magnesium chloride in sequence, adjust the pH of the system to 9 with NaOH, stir for 25 minutes when the temperature rises to 80°C for aging, and finally wash, dehydrate, and dry to obtain low-smoke, flame-retardant powdered styrene-butadiene rubber products. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0041] (1) Preparation of acylated styrene-butadiene latex: same as Example 1.

[0042] (2) Preparation of functionalized expandable graphite: Same as Example 1.

[0043] (3) Preparation of flame-retardant powdered styrene-butadiene rubber: Take 100 parts of acylated styrene-butadiene latex a, 6 parts of functionalized expandable graphite a, and 50 parts of water into the coagulation kettle and stir and mix for 30 minutes, then heat up to 55 °C, Add 2.5 parts of potassium oleate and 3.5 parts of magnesium chloride in sequence, adjust the pH of the system to 9 with NaOH, stir for 25 minutes when the temperature rises to 80°C for aging, and finally wash, dehydrate, and dry to obtain low-smoke, flame-retardant powdered styrene-butadiene rubber products. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com