Production method for compound yellow rice wine saccharomycopsis

A production method and a rice wine yeast technology are applied in the production field of compound rice wine yeast strains, which can solve the problems of high waste water treatment cost, unsatisfactory rice wine flavor, long drying time, etc., and achieve low environmental protection treatment cost and great popularization and application value. , the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

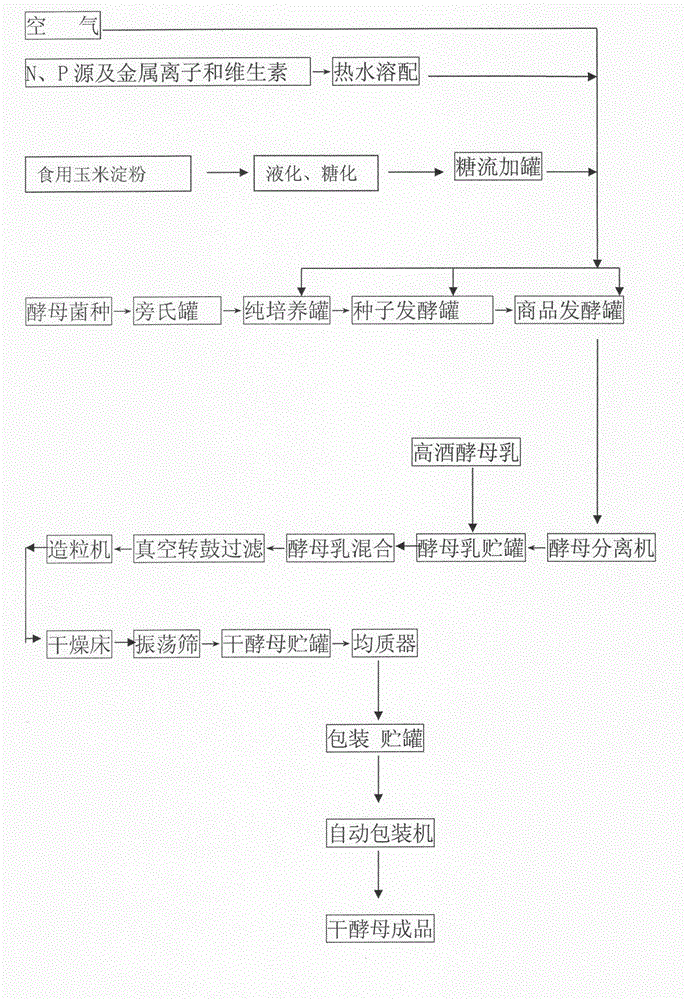

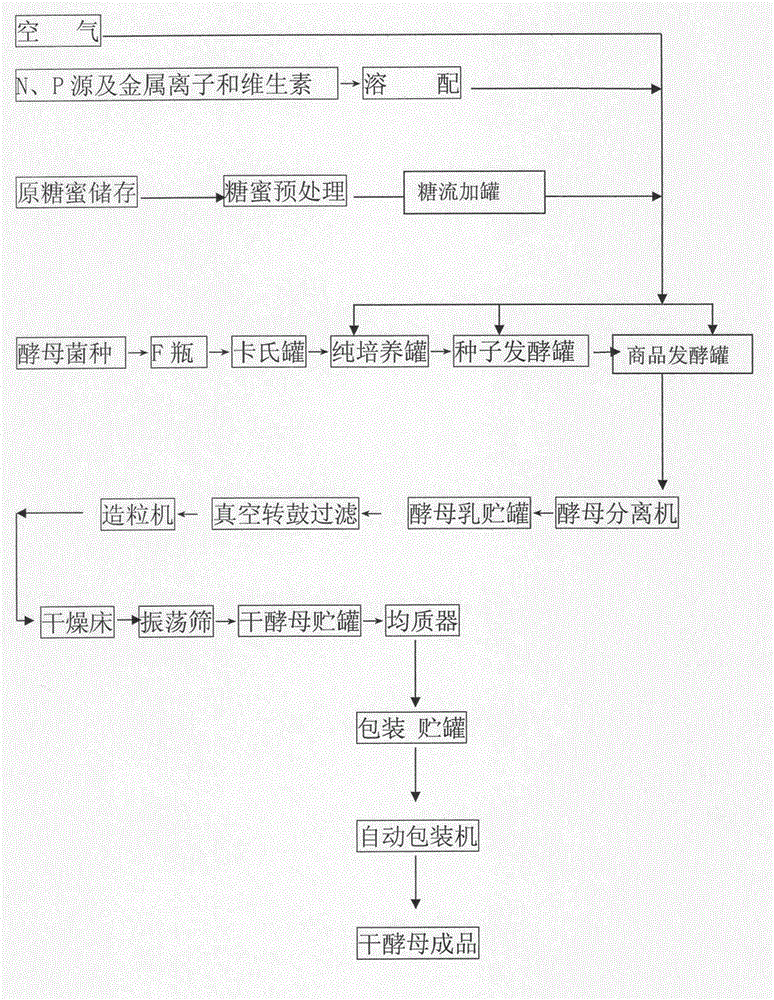

[0007] The specific method of yellow rice wine yeast production is:

[0008] 1. Screening, rejuvenation and pure culture of rice wine yeast: excellent yeast strains isolated from Shaoxing rice wine mash are screened, rejuvenated, preserved and cultivated in ampoules;

[0009] 2. Treatment of carbon, nitrogen and phosphorus sources used in yeast fermentation: select high-quality cornstarch, adjust the processing water to 16-18 degrees Baume, add acid to adjust the pH value to 5.2-5.8, and then add 0.5-1‰ high-temperature-resistant α- Amylase, fully dissolved, liquefied and hydrolyzed by a high-temperature injector, cooled to 60 degrees after passing the iodine test, and then entered the saccharification tank for saccharification, adjusted the pH value to 4.2-4.4, added 0.5-1‰ glucoamylase, and kept saccharification for 10-24 hours Afterwards, heat up to inactivate the enzyme, keep warm for more than 1 hour, and filter through the plate and frame to obtain 27-32% hydrolyzed suga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com