Method for producing multiple kinds of monosaccharide through bamboo processing residues

A technology for processing residues and monosaccharides, applied in the field of monosaccharide preparation, can solve the problems of aggravation, large loss of cellulose and hemicellulose, unsuitable lignocellulose pretreatment methods, etc., achieve good practicability and improve accessibility degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 100g of absolutely dried bamboo chips into a 1L stainless steel tubular digester, add NaOH and NaOH at a solid-to-liquid ratio of 1:5 2 S, the degree of sulfide is 20%, the amount of alkali is 2-10% (referring to NaOH+Na 2 S content, as Na 2 O meter) cooking liquor. After pre-soaking at 80°C for 20min, the temperature was raised to 160°C at a rate of 2°C / min and kept for 1h. Immediately after the reaction, take out the digester and immerse it in cold water, add distilled water to the cooked product to adjust the solid content to 5%, refine the pulp in a disc refiner at 3000 rpm for 30 minutes, separate the solid from the liquid, and wash the solid residue with distilled water to neutral. Put the solid slag into a sealed bag, balance the moisture in a refrigerator at 4°C for 2 days, measure the content of cellulose, xylan and lignin in the material, and calculate the recovery rate of cellulose, xylan and lignin removal rate, The results obtained are shown in Tabl...

Embodiment 2

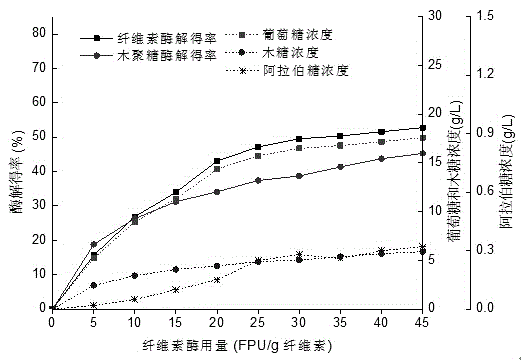

[0036] Take by weighing respectively the solid slag 7.59g (2.5g of absolute dry weight) that alkali consumption is 10% kraft method cooking pretreatment obtains in embodiment 1 in 10 250mL conical flasks, in each conical flask, add 1mol / L citric acid buffer 2.5mL, add the cellulase that enzyme dosage is 0, 5, 10, 15, 20, 25, 30, 35, 40, 45FPU / g cellulose in each triangular flask respectively, in each triangular flask Add an appropriate amount of distilled water to the bottle to make the total water volume in the enzymatic hydrolysis system 50mL, mix the reaction system thoroughly with a glass rod, cover the cap, and perform enzymatic hydrolysis in a constant temperature shaker at 150 rpm and 50°C for 48 hours. After the hydrolysis, the hydrolyzate was centrifuged at 4000 rpm for 10 min, and the supernatant was taken to measure the concentration of glucose, xylose and arabinose, and the enzymatic hydrolysis yield was calculated. Among them, cellulose enzymatic hydrolysis yield ...

Embodiment 3

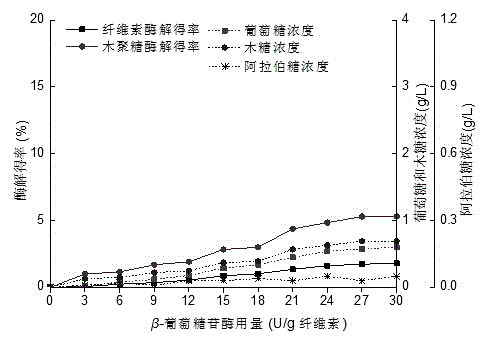

[0039] Take by weighing respectively the solid slag 7.59g (2.5g of absolute dry weight) obtained by the kraft method cooking pretreatment that alkali consumption is 10% in embodiment 1 in 11 250mL conical flasks, add 1mol / L in each conical flask Citrate buffer 2.5mL, add the β-glucosidase that consumption is 0,3,6,9,12,15,18,21,24,27,30U / g cellulose in each Erlenmeyer flask respectively, in Add an appropriate amount of distilled water to each flask to make the total volume of water in the enzymolysis system 50mL, mix the reaction system well with a glass rod, cover the lid, and enzymolyze in a constant temperature shaker at 150 rpm and 50°C for 48 hours . After the hydrolysis, the hydrolyzate was centrifuged at 4000 rpm for 10 min, and the supernatant was taken to measure the concentration of glucose, xylose and arabinose, and the enzymatic hydrolysis yield was calculated.

[0040] The effects of different amounts of β-glucosidase on the enzymatic hydrolysis yield of cellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com