Method for preparing silver plating PEEK tube for in-tube solid phase microextraction

An extraction and chemical silver plating technology, which is applied in solid solvent extraction, liquid chemical plating, metal material coating process, etc. Highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 : Preparation of 20 cm long 0.1 mm inner diameter silver-coated PEEK tubing

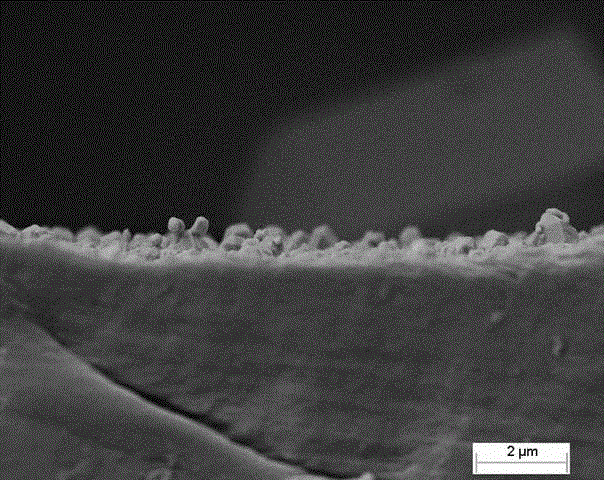

[0017] Take a PEEK tube with a length of 20 cm and an inner diameter of 0.1 mm, wash it with dilute hydrochloric acid, water, and methanol in order to remove impurities on the inner surface, and inject an electroless silver plating reaction solution mixed with silver ammonia solution and potassium sodium tartrate solution. The molar ratio of silver ammonium ions to potassium sodium tartrate is 1:1, the mass percentage of potassium sodium tartrate is 20%, the controlled reaction temperature is 20°C, after reacting for 3 hours, rinse with water and methanol successively, and dry with nitrogen, Heating and aging at 50 ℃ for 0.5 hours in a nitrogen protection environment, the number of electroless silver plating was 1 time, and a silver coating with a suitable thickness was obtained. The scanning electron microscope image of the prepared silver coating is attached figure 1 shown.

Embodiment 2

[0018] Example 2 : Preparation of 30 cm long 0.18 mm inner diameter silver-coated PEEK tubing

[0019] Take a PEEK tube with a length of 30 cm and an inner diameter of 0.18 mm, wash it with dilute hydrochloric acid, water, and methanol in order to remove impurities on the inner surface, and inject an electroless silver plating reaction solution mixed with silver ammonia solution and potassium sodium tartrate solution. The molar ratio of silver ammonium ions to potassium sodium tartrate is 1:2, the mass percentage of potassium sodium tartrate is 15%, the controlled reaction temperature is 25°C, after reacting for 6 hours, rinse with water and methanol successively, and dry with nitrogen, Heating and aging at 70 ℃ for 2.5 hours in a nitrogen-protected environment, the number of electroless silver plating was 2 times, and a silver coating with a suitable thickness was obtained.

Embodiment 3

[0020] Example 3 : Preparation of 50 cm long 0.25 mm inner diameter silver-coated PEEK tubing

[0021] Take a PEEK tube with a length of 50 cm and an inner diameter of 0.25 mm, wash it with dilute hydrochloric acid, water, and methanol in order to remove impurities on the inner surface, and inject an electroless silver plating reaction solution mixed with silver ammonia solution and potassium sodium tartrate solution. The mol ratio of silver ammonium ion and potassium sodium tartrate is 1:1.8, and the mass percentage composition of potassium sodium tartrate is 10%, and the control reaction temperature is 30 ℃, and after reacting for 9 hours, rinse with water and methanol successively, and after drying with nitrogen, Heating and aging at 80 ℃ for 4 hours in a nitrogen-protected environment, the number of electroless silver plating was 4 times, and a silver coating with a suitable thickness was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com