Method for measuring total iron

A solution and alkali fusion technology, applied in the field of analysis and detection, can solve problems such as polluting the environment, harmful to analysts' health, and inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take the GSB H 3005-97 national standard sample as the sample, which contains 56.09% iron.

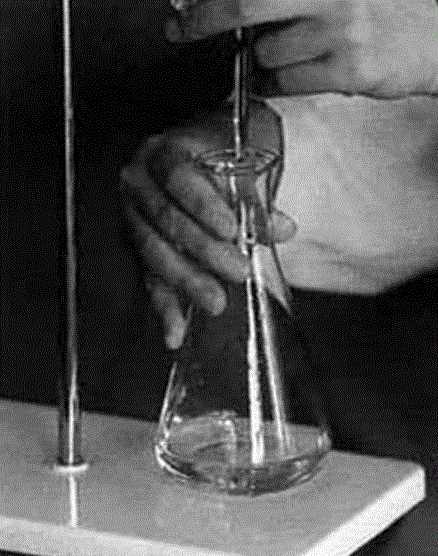

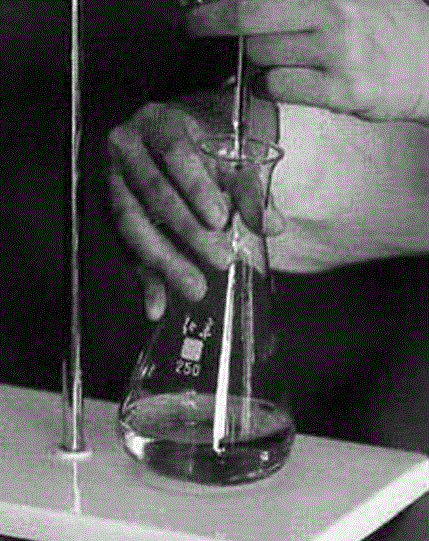

[0037] 1. Weigh 0.2g of the sample into a corundum crucible, add 2-3g of sodium peroxide, mix well, then add 1g of sodium peroxide to cover, melt in a muffle furnace at 600-700°C for 10min, take it out and cool it, and first use hot water After leaching, add 15ml of hydrochloric acid, heat to near boiling on an electric furnace, add 100g / l tin dichloride dropwise while hot to reduce to light yellow, and cool to room temperature with running water.

[0038] 2. Add 15 drops of 250g / L sodium tungstate to the solution, add titanium trichloride solution dropwise until the tungsten blue, add 2-3 drops of copper sulfate solution, shake to make the tungsten blue disappear, add 10ml sulfur phosphorus mixed acid (2 +3), 10 drops of sodium diphenylamine sulfonate, titrated with potassium dichromate standard solution to purple as the end point.

[0039] 3. The measurement result is 55.90% ...

Embodiment 2

[0041] Take the GBW 07170 national standard sample as the sample, which contains 8.93% iron.

[0042] 1. Weigh 0.2g of the sample into a corundum crucible, add 2-3g of sodium peroxide, mix well, then add 1g of sodium peroxide to cover, melt in a muffle furnace at 600-700°C for 10min, take it out and cool it, and first use hot water After leaching, add 15ml of hydrochloric acid, heat to near boiling on an electric furnace, add 100g / l tin dichloride dropwise while hot to reduce to light yellow, and cool to room temperature with running water.

[0043] 2. Add 15 drops of 250g / L sodium tungstate to the solution, add titanium trichloride solution dropwise until the tungsten blue, add 2-3 drops of copper sulfate solution, shake to make the tungsten blue disappear, add 10ml sulfur phosphorus mixed acid (2 +3), 10 drops of sodium diphenylamine sulfonate, titrated with potassium dichromate standard solution to purple as the end point.

[0044] 3. The measurement result is 8.90% iron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com